Lithium-rich manganese-based precursor, preparation method thereof and lithium-rich manganese-based positive electrode material

A technology of lithium-rich manganese-based cathode materials, applied in chemical instruments and methods, battery electrodes, inorganic chemistry, etc. Performance and other issues, to achieve good electrochemical performance, uniform shape, good particle size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

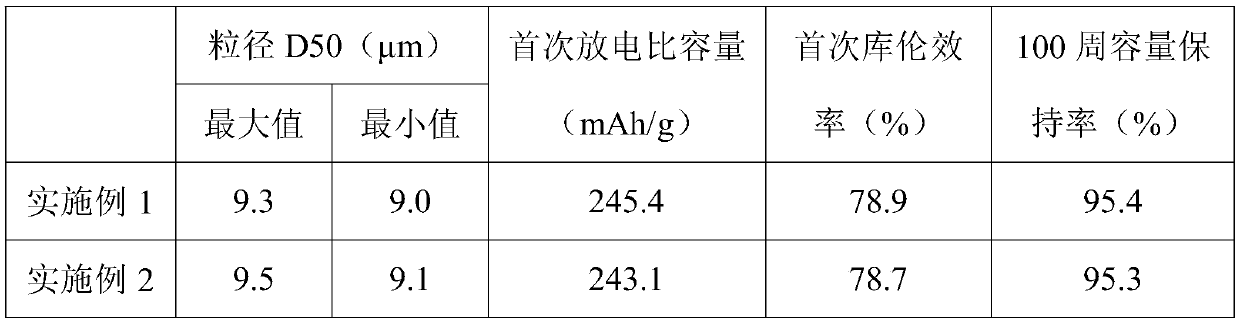

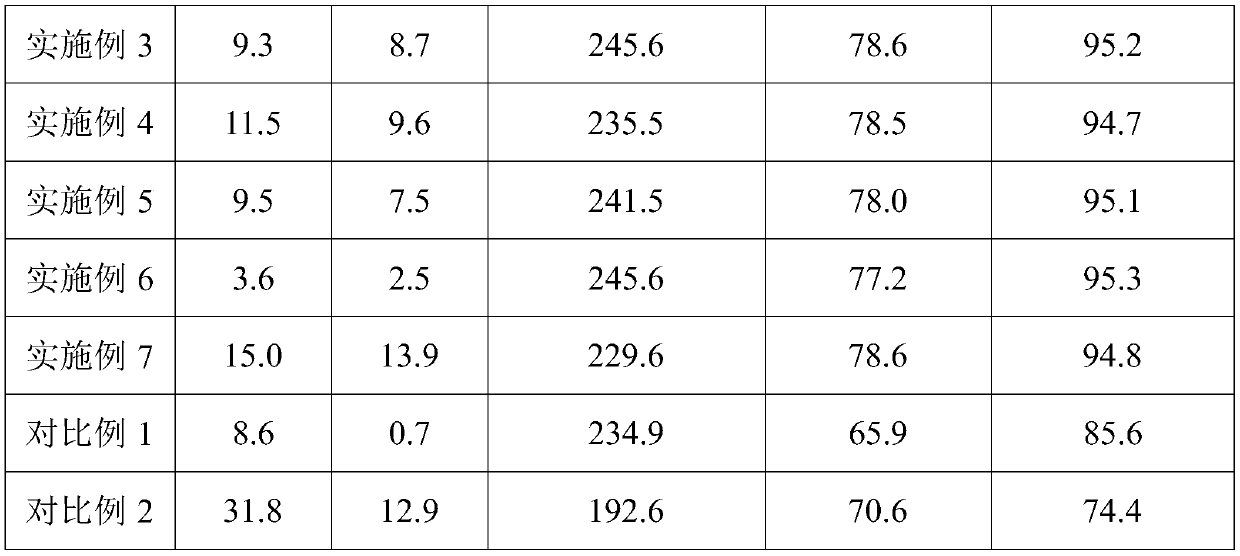

Examples

Embodiment 1

[0064] A preparation method of a lithium-rich manganese-based positive electrode material comprises the steps of:

[0065] (1) be 0.2:0.08:0.7:0.02 by the mol ratio of nickel sulfate, cobalt sulfate, manganese sulfate and aluminum sulfate, nickel sulfate, cobalt sulfate, manganese sulfate and aluminum sulfate are dissolved in water, obtain metal ion total molar concentration as 2mol / L mixed salt solution;

[0066] (2) In the mixed salt solution, adding molar concentration is 5mol / L ammoniacal liquor, the total molar ratio of ammoniacal liquor and metal ion in the mixed salt solution is 0.1:1, adding molar concentration is 10mol / L sodium hydroxide to adjust pH The value is 12, and the reaction precursor is obtained;

[0067] (3) The reaction precursor is subjected to intermittent ultrasonic vibration, the particle size in the reaction system is greater than 9.5 μm, the ultrasonic vibration is turned on, the particle size in the reaction system is less than 8.5 μm, the ultrason...

Embodiment 2

[0071] The difference from Example 1 is that the power density of ultrasonic vibration in step (3) is 5W / L.

Embodiment 3

[0073] The difference from Example 1 is that the power density of ultrasonic vibration in step (3) is 500W / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com