Prepreg composition with low dielectric constant, copper-clad plate and method for manufacturing same

A composition and prepreg technology, applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve the problems of substrate dielectric performance degradation and achieve low dielectric constant, dielectric loss, and thermal expansion coefficient Low, effect of improving dispersion and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

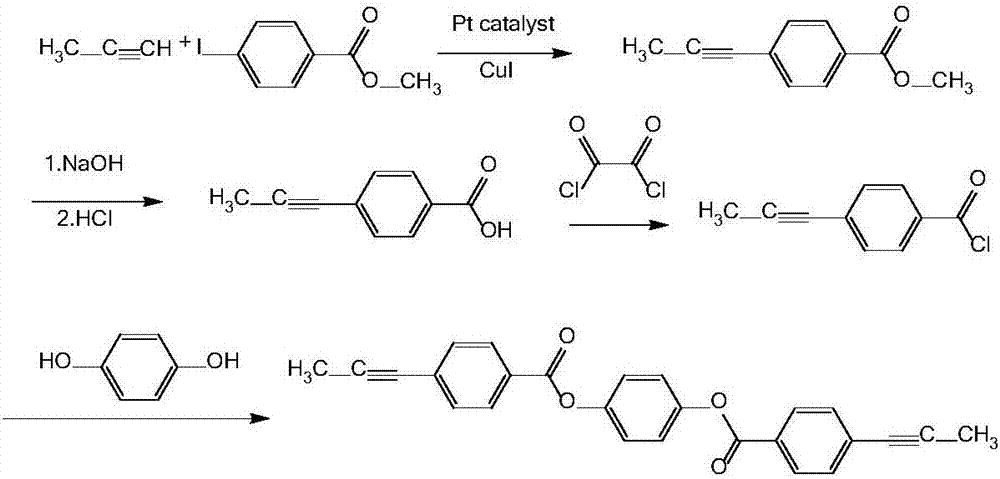

Method used

Image

Examples

Embodiment 1

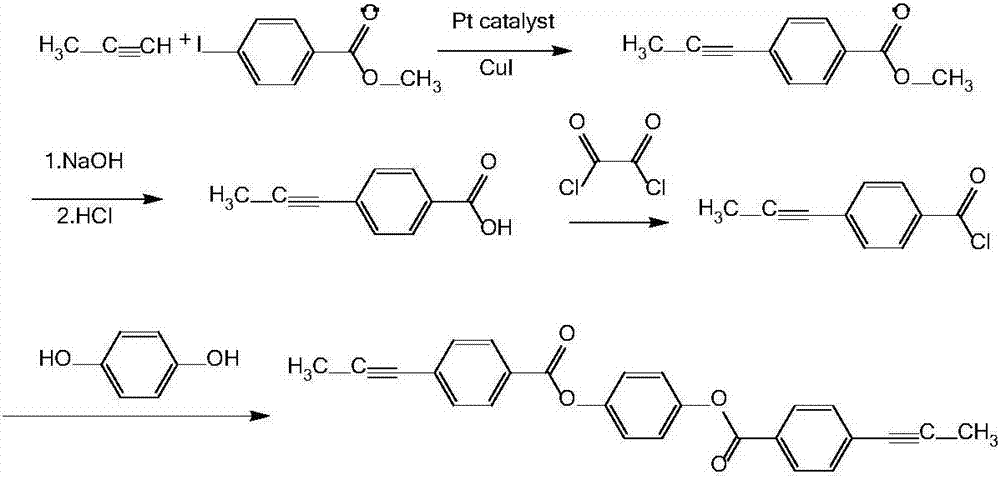

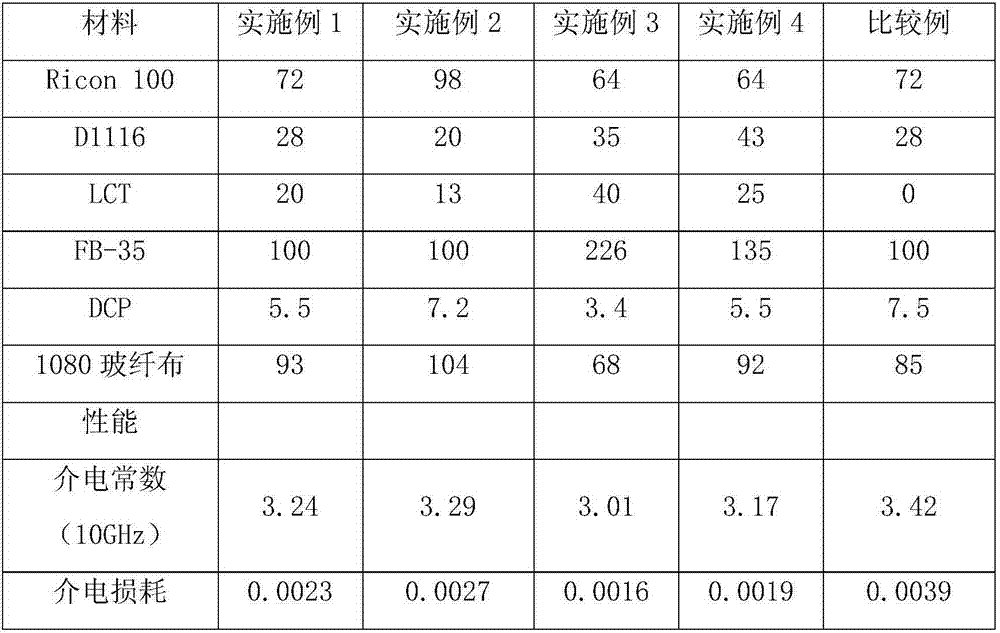

[0039] Mix 72 parts by weight of ricon100, 28 parts by weight of D1116, 20 parts by weight of LCT, 100 parts by weight of FB-35, and 6.8 parts of DCP, adjust to a suitable viscosity with xylene solvent, stir and mix evenly to make the filler uniform Dispersed in the resin, the prepared glue. Use 1080 glass fiber cloth to impregnate the above glue solution, and then dry to remove the solvent to obtain a non-sticky prepreg. Lay four prepregs together, cover both sides with copper foil with a thickness of 1 oz, and perform temperature program curing in a press with a curing pressure of 60Kg / cm 2 , the curing temperature was 170°C for 2h, and then heated to 270°C and cured for 1h to make a circuit substrate. The wireless data are shown in Table 2.

Embodiment 2

[0040] Embodiments 2, 3, and 4 have the same manufacturing process as that of Embodiment 1, and the ratio of materials is changed as shown in Table 2.

[0041] 3. Comparative example and test example

[0042] The manufacturing process is the same as that of Example 1, except that the thermosetting liquid crystal resin LCT is removed, and the material ratio is shown in Table 2. The physical properties of the circuit substrates prepared according to the above-mentioned different ingredients were analyzed, and the results are shown in Table 2.

[0043] Table 2

[0044]

[0045]

[0046] From the results of physical property data in Table 2, it can be seen that compared with the comparative examples, the dielectric constant and dielectric loss of the circuit substrate materials produced in Examples 1, 2, 3, and 4 are lower, and the high-frequency performance is good. Due to the addition of the thermosetting liquid crystal resin, the cross-linking density of the material is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com