Graphene array-loaded lithium titanate/carbon nanotube composite array electrode and preparation method and application thereof

A carbon nanotube composite, graphene array technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve problems such as limited application and low electronic conductivity, and achieve multiple active sites, ultra-high rate performance, and electrode performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

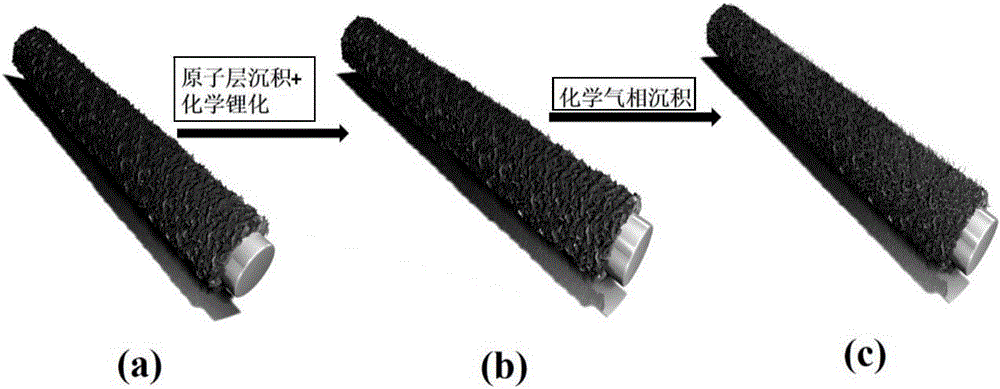

[0039] (1) Vertical graphene (VG) arrays were grown on carbon cloth by microwave plasma enhanced chemical vapor deposition (MPECVD). The carbon was arranged in a tube furnace, and 30 sccm of methane and 40 sccm of hydrogen were introduced to react at a temperature of 400° C. for 1 hour.

[0040] (2) Using atomic layer deposition (ALD) technology to grow TiO on the vertical graphene obtained in step (1) 2 , Ti source and O source are titanium tetrachloride and water, respectively, and the reaction temperature is 200 °C.

[0041] (3) Dissolve 2.9372g lithium hydroxide in 70mL water to form solution A, the concentration of lithium hydroxide in solution A is 1molL -1 .

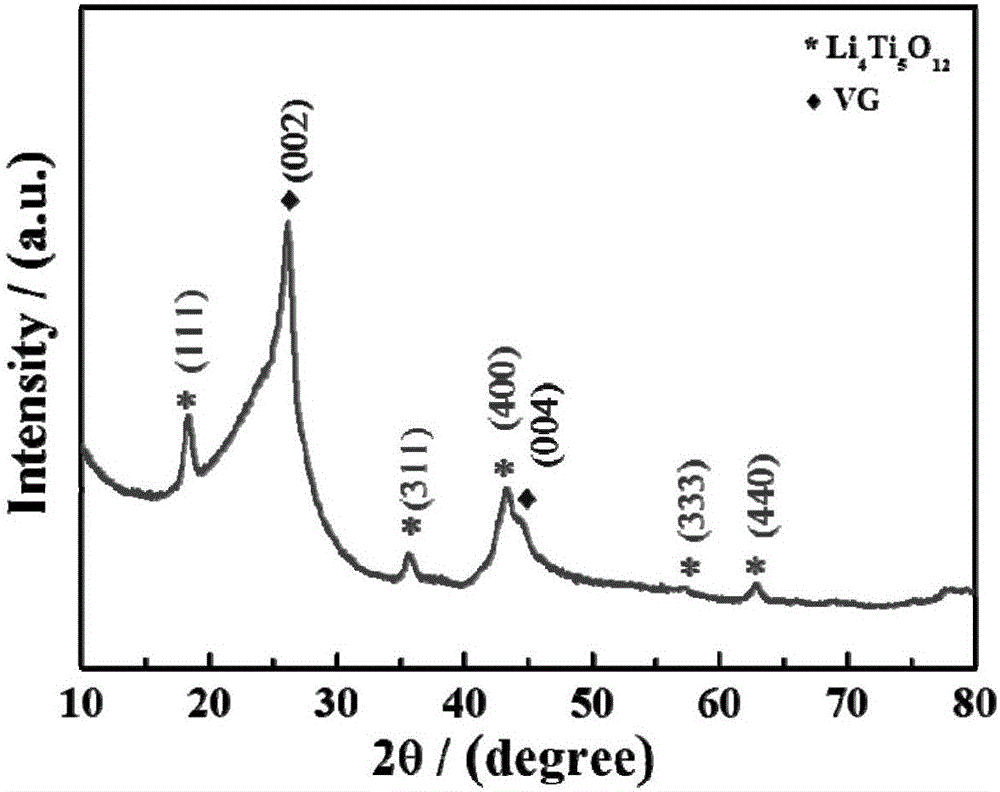

[0042] (4) Place the vertical graphene-supported titania composite electrode material obtained in step (2) in solution A, perform a hydrothermal reaction at 80°C for 1 hour, then wash and dry, and finally in an argon protective atmosphere, at 500°C Calcined for 2 hours to obtain a VG / LTO composite array structu...

Embodiment 2

[0049] (1) Vertical graphene arrays were grown on carbon cloth by microwave plasma enhanced chemical vapor deposition (MPECVD). The carbon was arranged in a tube furnace, and 40 sccm of methane and 50 sccm of hydrogen were introduced to react at a temperature of 450° C. for 2 hours.

[0050] (2) Using atomic layer deposition (ALD) technology to grow TiO on the vertical graphene obtained in step (1) 2 , Ti source and O source are titanium tetrachloride and water, respectively, and the reaction temperature is 250 °C.

[0051] (3) Dissolve 5.8744g lithium hydroxide in 70mL water to form solution A, the concentration of lithium hydroxide in solution A is 2molL -1 .

[0052] (4) Place the vertical graphene-loaded titania composite electrode material obtained in step (2) in solution A, perform a hydrothermal reaction at 85°C for 1.5 hours, then wash and dry, and finally in an argon protective atmosphere, at 550°C Calcined for 2.5 hours to obtain a VG / LTO composite array structure...

Embodiment 3

[0057] (1) Vertical graphene arrays were grown on carbon cloth by microwave plasma enhanced chemical vapor deposition (MPECVD). The carbon was placed in a tube furnace, 50 sccm of methane and 60 sccm of hydrogen were introduced, and the reaction was carried out at a temperature of 500° C. for 3 hours.

[0058] (2) Using atomic layer deposition (ALD) technology to grow TiO on the vertical graphene obtained in step (1) 2 , Ti source and O source are titanium tetrachloride and water, respectively, and the reaction temperature is 300 °C.

[0059] (3) Dissolve 8.8116g lithium hydroxide in 70mL water to form solution A, the concentration of lithium hydroxide in solution A is 3molL -1 .

[0060] (4) Place the vertical graphene-supported titania composite electrode material obtained in step (2) in solution A, react with hydrothermal reaction at 90°C for 2 hours, then wash and dry, and finally in an argon protective atmosphere, at 600°C Calcined for 3 hours to obtain a VG / LTO compos...

PUM

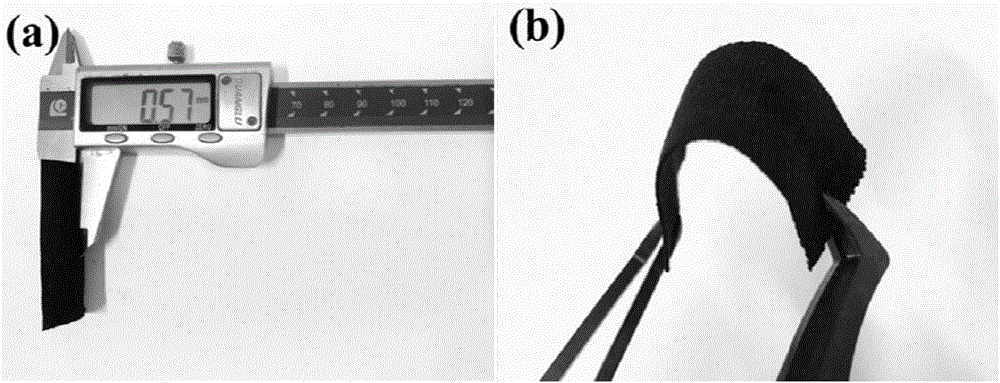

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com