Cigarette water capsule with water and hydrotropic substance as core materials and manufacturing method of cigarette water capsule with water and hydrotropic substance as core materials

A water-soluble substance and hydrophilic technology, applied in the field of preparation of the water bag, can solve the problems of not being suitable for large-scale industrial production, harsh conditions, complicated packaging process, etc., so that the particle size and thickness can be easily controlled and easily The effect of realization and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

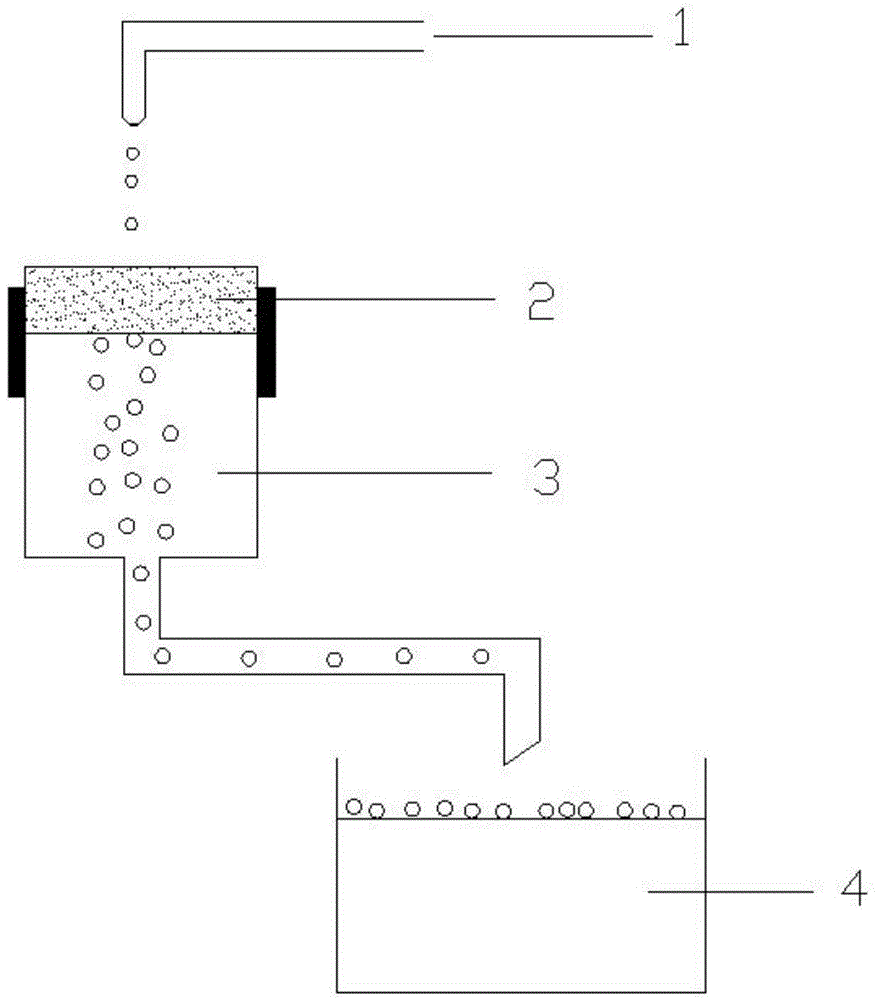

Embodiment 1

[0033] Example 1: Weigh beeswax and polyethylene according to the weight ratio of 8:2, mix the two and heat and melt them. When the mixture is completely melted and mixed, the temperature is kept constant at 110°C; preparation of core material: according to 50:15:35 Above-mentioned weight ratio, take by weighing pure water, ginseng essence and propylene glycol, and place it at 2 ℃; Through the orifice device, the weight parts of the wall material and the core material are respectively 50 weight parts and 50 weight parts, and the core material is passed through a pump to The flow rate of 600-1000 microliters / min drops the core material droplets into the melted wall material liquid. Due to the effect of surface tension, the cooled core material is wrapped by the hot melted wall material and forms a water pocket to sink, causing the wall to sink. The core material is wrapped with the core material; the formed water bladder is cured in a silicone oil coagulation bath at a temperatu...

Embodiment 2

[0035]Example 2: Weigh Sichuan wax and ethylene-vinyl acetate copolymer according to the weight ratio of 9:1, mix the two and heat and melt, until the mixture is completely melted and mixed, so that the temperature is constant at 1200 ° C; Preparation of core material: According to the above weight ratio of 60:15:25, pure water, ginseng essence and glycerin were weighed and placed at 2°C; through the orifice device, the weight parts of the wall material and the core material were 40 parts by weight and 60 parts by weight respectively , the core material drops the core material droplets into the melted wall material liquid through the pump at a flow rate of 600-1000 μl / min. Due to the effect of surface tension, the cooled core material is wrapped by the hot melted wall material to form water The bladder sinks, so that the wall material wraps the core material; the formed water bladder is cured in a silicone oil coagulation bath at a temperature of 12°C; cleaning and drying: use ...

Embodiment 3

[0037] Example 3: Weigh the microcrystalline wax and polyethylene according to the weight ratio of 8:2, mix the two and heat and melt them. When the mixture is completely melted and mixed, the temperature is kept constant at 130°C; preparation of core material: according to 68:12 : 30 above-mentioned weight ratios, take by weighing pure water, blueberry essence and sodium citrate, place it under 2 ℃; The core material is dripped into the melted wall material liquid through a pump at a flow rate of 600-1000 microliters / min. Due to the effect of surface tension, the cooled core material is wrapped by the hot melted wall material and forms a water pocket. sink, so that the wall material wraps the core material; solidify the formed water bladder in a silicone oil coagulation bath at a temperature of 12°C; cleaning and drying: use 90% concentration of ethanol aqueous solution to wash the solidification bath material remaining on the surface of the solidified water bladder , blow dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com