Sewage treatment material and preparation method thereof

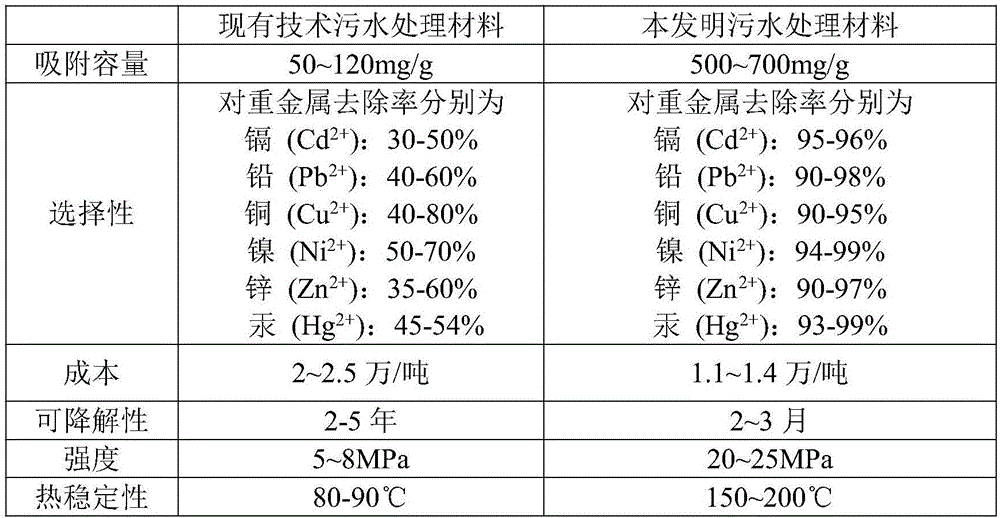

A sewage treatment and pretreatment technology, applied in the direction of water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of ineffective application of sewage treatment, complex preparation process, and poor sewage treatment effect Good and other questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A. In parts by weight, 10 parts of bamboo charcoal are added to a water bath and boiled for 5 minutes to remove dust and surface residues, then the bamboo charcoal is added to the reactor and activated for 10 minutes at 400 ° C under steam conditions, and finally cooled for 10 minutes to obtain pretreatment bamboo charcoal;

[0023] B, in parts by weight, the pretreated bamboo charcoal obtained in the step (A) is mixed with 1 part of hydrotalcite and 1 part of diatomaceous earth, and added to a grinder and ground to 100 orders to obtain mixture A;

[0024] C, in parts by weight, 5 parts of mixture A obtained in step (B) and porous starch, 1 part of carboxymethyl cellulose, 10 parts of polyvinyl alcohol, 1 part of amino resin and solvent are added in a high-speed mixer and mixed uniformly, the temperature Control at 50°C to obtain mixture B;

[0025] D. In parts by weight, add the mixture B obtained in step (C) into the screw extruder, the screw extruder speed is contro...

Embodiment 2

[0027] A. In parts by weight, 15 parts of bamboo charcoal are added to a water bath and boiled for 8 minutes to remove dust and surface residues, then the bamboo charcoal is added to the reactor and activated for 20 minutes at 500 ° C under steam conditions, and finally cooled for 15 minutes to obtain pretreatment bamboo charcoal;

[0028] B, in parts by weight, mix the pretreated bamboo charcoal obtained in the step (A) with 3 parts of hydrotalcite and 3 parts of diatomaceous earth, add in the grinder and grind to 300 mesh, obtain mixture A;

[0029] C, in parts by weight, 8 parts of mixture A obtained by step (B) and porous starch, 4 parts of carboxymethyl cellulose, 15 parts of polyvinyl alcohol, 3 parts of amino resin and solvent are added in high-speed mixer and mixed uniformly, temperature Control at 80°C to obtain mixture B;

[0030] D, in parts by weight, add the mixture B obtained in step (C) into the screw extruder, the screw extruder speed is controlled at 400r / min...

Embodiment 3

[0032] A. In parts by weight, 20 parts of bamboo charcoal are added to a water bath and boiled for 10 minutes to remove dust and surface residues, then the bamboo charcoal is added to the reactor and activated for 30 minutes at 600 ° C under steam conditions, and finally cooled for 20 minutes to obtain pretreatment bamboo charcoal;

[0033] B, in parts by weight, the pretreated bamboo charcoal obtained in the step (A) is mixed with 5 parts of hydrotalcite and 5 parts of diatomaceous earth, and added to a grinder and ground to 500 mesh to obtain mixture A;

[0034] C, in parts by weight, 10 parts of mixture A obtained by step (B) and porous starch, 5 parts of carboxymethyl cellulose, 20 parts of polyvinyl alcohol, 5 parts of amino resin and solvent are added in high-speed mixer and mix uniformly, temperature Control at 100°C to obtain mixture B;

[0035] D. In parts by weight, add the mixture B obtained in step (C) into the screw extruder, the screw extruder speed is controlle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com