Preparation method of graphene-carbon nanotube-nano tin dioxide three-dimensional composite material and product thereof

A nano-tin dioxide, carbon nanotube technology, applied in the directions of tin oxide, carbon compounds, chemical instruments and methods, can solve the problems of complex preparation process, expensive equipment, structural defects, etc., and achieve uniform distribution, low cost, Lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

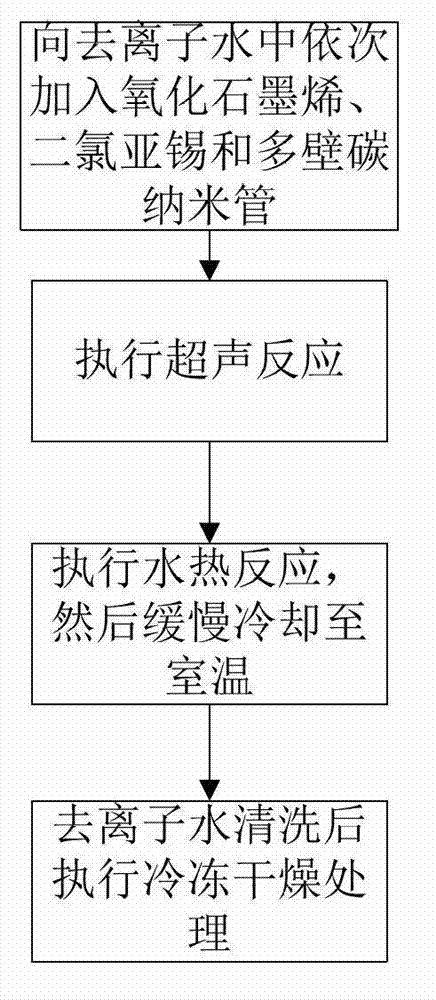

[0032]Using deionized water as a solvent, add graphene oxide, stannous chloride and multi-walled carbon nanotubes as solutes in sequence and perform mixing and stirring for about 30 minutes. The proportion of ingredients is controlled as per 100ml of deionized water, graphene oxide, The mass ratio of stannous and multi-walled carbon nanotubes is 120mg: 12mg: 60mg, respectively;

[0033] Next, the obtained mixed solution was ultrasonically reacted at a temperature of 25°C for 1 hour, wherein the ultrasonic power was set to 300W, thereby generating reactants comprising graphene oxide, tin dioxide and multi-walled carbon nanotube precursors;

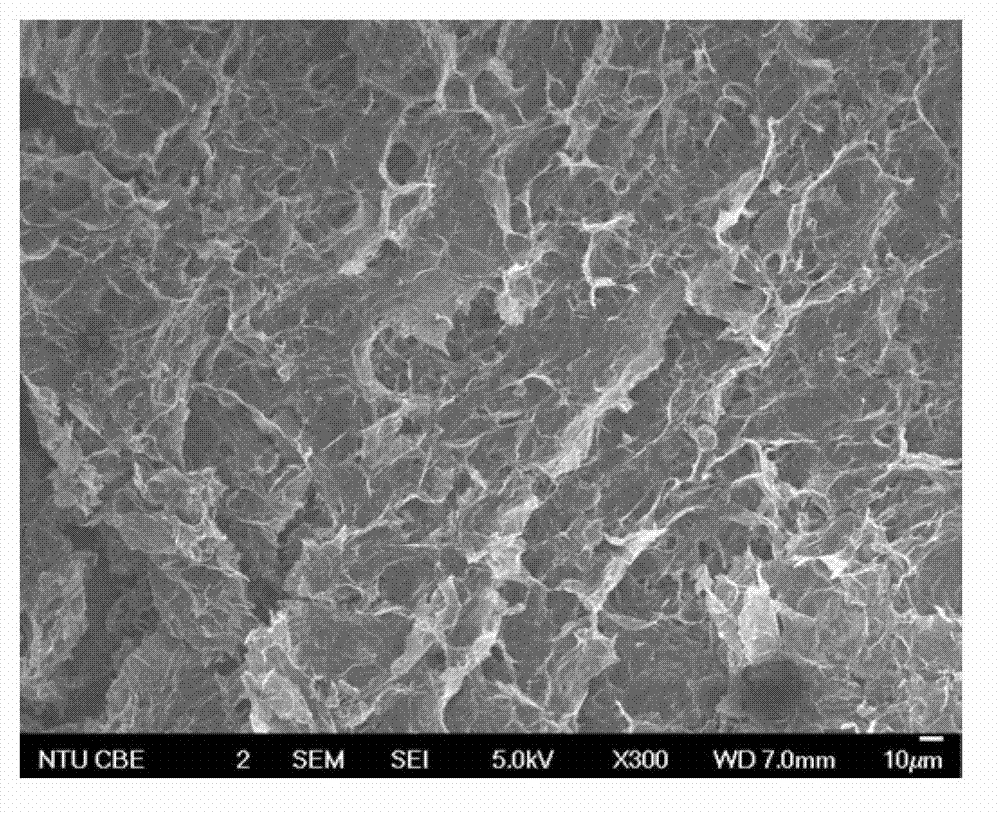

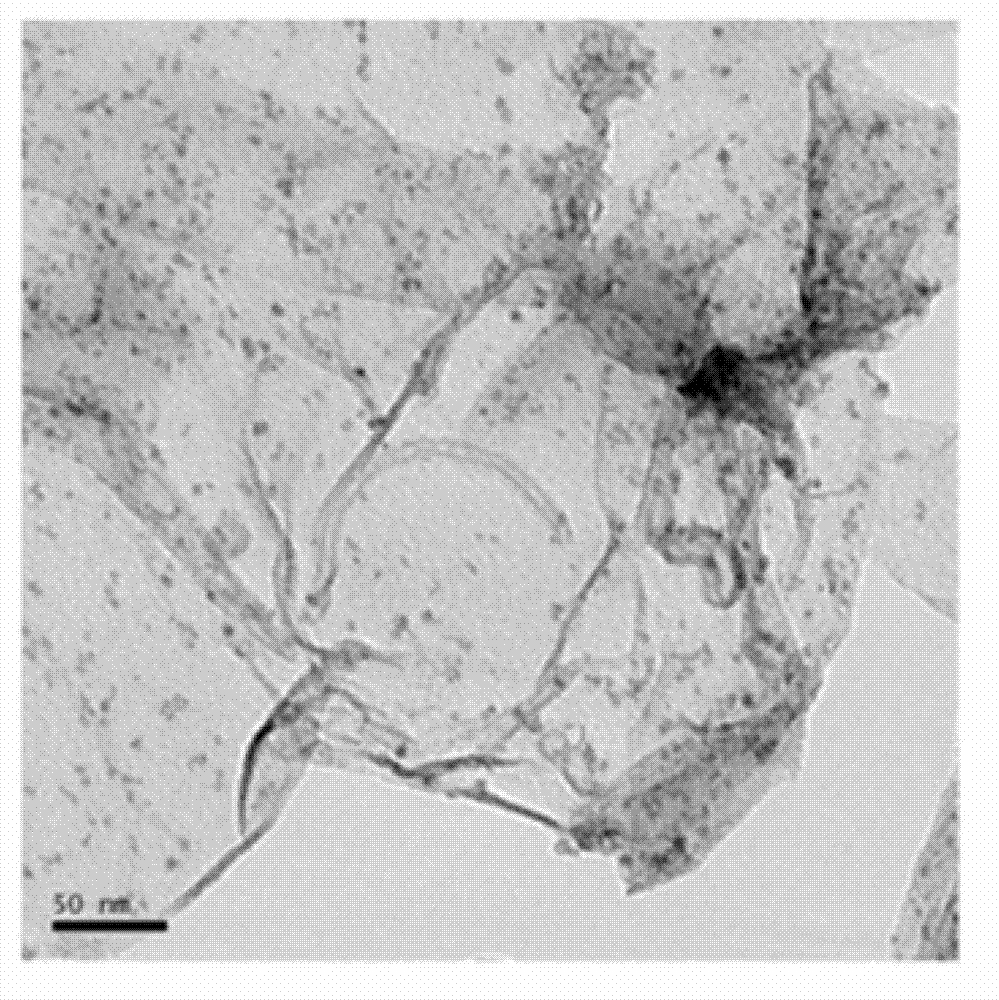

[0034] The resulting solution is transferred to a reaction vessel such as a polytetrafluoroethylene hydrothermal kettle, hydrothermally treated at a temperature of 120°C for 72 hours, and then slowly cooled to room temperature, which is about 25°C, to obtain a graphene-carbon with a three-dimensional structure The nanotube-nanometer tin dio...

Embodiment 2

[0036] Using deionized water as a solvent, add graphene oxide, stannous chloride and multi-walled carbon nanotubes as solutes in sequence and perform mixing and stirring for about 30 minutes. The proportion of ingredients is controlled as per 100ml of deionized water, graphene oxide, The mass ratio of stannous and multi-walled carbon nanotubes is 160mg: 16mg: 100mg respectively;

[0037] Next, the obtained mixed solution was ultrasonically reacted at a temperature of 40°C for 2 hours, wherein the ultrasonic power was set to 100W, thereby generating reactants comprising graphene oxide, tin dioxide and multi-walled carbon nanotube precursors;

[0038] The resulting solution is transferred to a reaction vessel such as a polytetrafluoroethylene hydrothermal kettle, hydrothermally treated at a temperature of 200°C for 12 hours, and then slowly cooled to room temperature to obtain a graphene-carbon nanotube-nanodicarbonate with a three-dimensional structure. The tin oxide composite ...

Embodiment 3

[0040] Using deionized water as a solvent, add graphene oxide, stannous chloride and multi-walled carbon nanotubes as solutes in sequence and perform mixing and stirring for about 30 minutes. The proportion of ingredients is controlled as per 100ml of deionized water, graphene oxide, The mass ratio of stannous and multi-walled carbon nanotubes is 130mg: 13mg: 80mg respectively;

[0041] Next, the obtained mixed solution was ultrasonically reacted at a temperature of 40°C for 2 hours, wherein the ultrasonic power was set to 200W, thereby generating reactants comprising graphene oxide, tin dioxide and multi-walled carbon nanotube precursors;

[0042] The resulting solution is transferred to a reaction vessel such as a polytetrafluoroethylene hydrothermal kettle, hydrothermally treated at a temperature of 180°C for 24 hours, and then slowly cooled to room temperature to obtain a graphene-carbon nanotube-nanodicarbonate with a three-dimensional structure. The tin oxide composite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com