Non-formaldehyde adhesive particle board and preparation method thereof

A particleboard and aldehyde-free glue technology, which is applied in the field of aldehyde-free glue particleboard and its preparation, can solve problems such as poor initial viscosity, and achieve the effect of improving hot pressing efficiency and facilitating industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

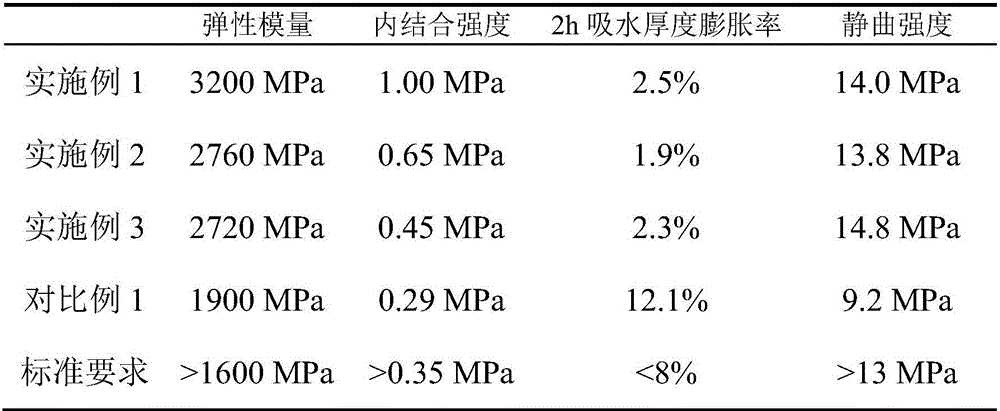

Examples

Embodiment 1

[0036] The formaldehyde-free soybean gum used in the surface layer of this example is composed as follows in parts by weight:

[0037] Defatted soy flour: 30 parts

[0038] Sodium hydroxide (acid-base regulator): 0.3 parts

[0039]Silane coupling agent KH560 (crosslinking agent): 5 parts

[0040] Casson (antifungal agent): 0.7 parts

[0041] Polyether modified polysiloxane (leveling agent, BYK-320): 0.5 parts

[0042] Water: 48.5 parts

[0043] Rosin emulsion (tackifier, 40% solid content): 25 parts.

[0044] Before sizing, mix sodium hydroxide, silane coupling agent, Cathone, polyether modified polysiloxane, and water evenly, and use it as a liquid component for sizing, defatted soybean flour as a powder component for sizing, and rosin emulsion As another component, the sizing is performed separately, and the formaldehyde-free soybean gum and the surface layer shavings are sized according to the weight ratio of 26:100. In this example, the formaldehyde-free soybean gum i...

Embodiment 2

[0047] The formaldehyde-free soybean gum used in the surface layer of this example is composed as follows in parts by weight:

[0048] Defatted soy flour: 20 parts

[0049] Citric acid (acid-base regulator): 5 parts

[0050] Epoxy resin (crosslinking agent): 10 parts

[0051] Copper sulfate (mold inhibitor): 1 part

[0052] Polyether modified polysiloxane (leveling agent, BYK-320): 1 part

[0053] Water: 50 parts

[0054] Terpene resin emulsion (tackifier, 40% solid content): 33 parts.

[0055] Before sizing, mix citric acid, epoxy resin, copper sulfate, polyether modified polysiloxane, and water evenly, and use it as a liquid component for sizing, defatted soy flour as a powder component for sizing, and terpene resin emulsion As another component, sizing alone, sizing formaldehyde-free soybean gum and surface shavings according to the weight ratio of 20:100, the core layer uses polyphenyl polymethylene polyisocyanate, polyphenyl polymethylene polyisocyanate Isocyanate, ...

Embodiment 3

[0058] The formaldehyde-free soybean gum used in the surface layer of this example is composed as follows in parts by weight:

[0059] Defatted soy flour: 20 parts

[0060] Oxalic acid (acid-base regulator): 5 parts

[0061] Epoxy resin (crosslinking agent): 10 parts

[0062] Copper sulfate (mold inhibitor): 1 part

[0063] Polyether modified polysiloxane (leveling agent, BYK-320): 1 part

[0064] Water: 50 parts

[0065] Rosin emulsion (tackifier, 40% solid content): 13 parts.

[0066] Before sizing, mix oxalic acid, epoxy resin, copper sulfate, polyether modified polysiloxane, and water evenly, and use it as a liquid component for sizing, defatted soybean flour as a powder component for sizing, and rosin emulsion as another The components are sizing separately, the formaldehyde-free soybean gum and the surface shavings are sizing according to the weight ratio of 20:100, the core layer uses toluene diisocyanate, and the toluene diisocyanate, water and core layer shavings...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static bending strength | aaaaa | aaaaa |

| Internal binding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com