Concrete anti-cracking reinforced self-repairing material and preparation method and application thereof

A self-repairing material, concrete technology, applied in the field of building materials, can solve problems such as easy cracking of concrete structures and lower overall strength, achieve good repair effect, fast repair speed, and improve crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

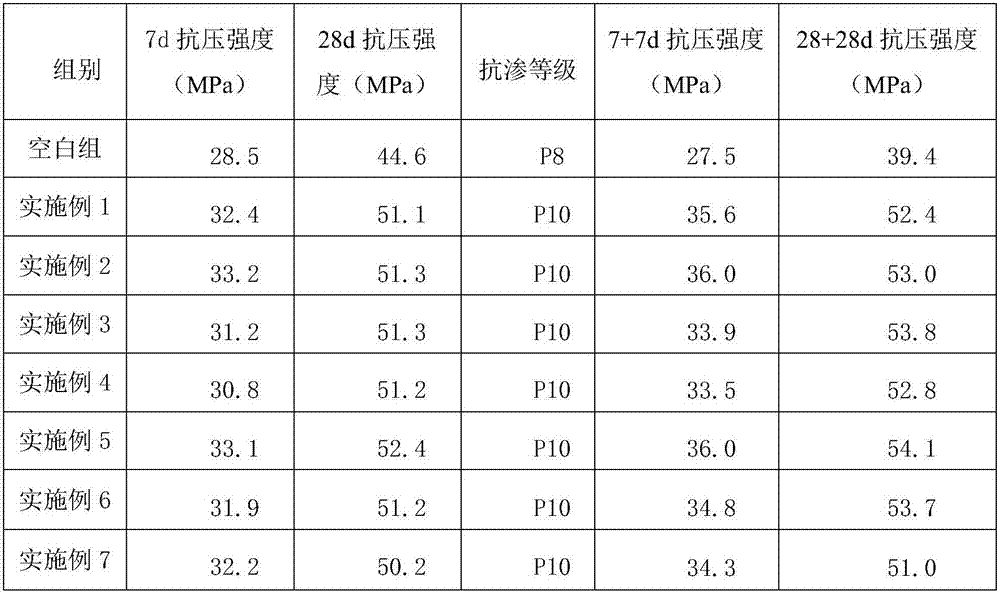

Embodiment 1

[0029] This embodiment provides a concrete anti-cracking reinforced self-repairing material. In parts by weight, the raw materials include the following components: 40 parts of calcium sulfoaluminate, 10 parts of calcium oxide, 20 parts of bentonite, 10 parts of talcum powder, 3 parts of calcium citrate 2 parts, 2 parts of calcium adipate, 15 parts of sodium carbonate.

[0030] The preparation method of the concrete anti-cracking reinforced self-repairing material described in this embodiment includes:

[0031] Step 1: take each component by said ratio for subsequent use;

[0032] Step 2: Mix the compact component with the water storage component, dry, and set aside;

[0033] Step 3: Mix and stir the mixture prepared in Step 2 with the plasticizing component, the complexing component, and the coagulation-regulating and enhancing component to obtain the self-restoring material.

Embodiment 2

[0035] This embodiment provides a concrete anti-cracking reinforced self-repairing material. In parts by weight, the raw materials include the following components: 45 parts of calcium sulfoaluminate, 10 parts of calcium oxide, 10 parts of diatomaceous earth, 5 parts of zeolite powder, and talcum powder 10 parts, 5 parts of calcium citrate, 15 parts of sodium bicarbonate.

[0036] The preparation method of the concrete anti-cracking reinforced self-repairing material described in this embodiment is the same as that described in Embodiment 1, and will not be repeated here.

Embodiment 3

[0038] This embodiment provides a concrete anti-cracking reinforced self-repairing material. In parts by weight, the raw materials include the following components: 40 parts of calcium sulfoaluminate, 5 parts of calcium oxide, 15 parts of bentonite, 10 parts of diatomite, and 5 parts of zeolite powder 15 parts of talcum powder, 2 parts of calcium citrate, and 8 parts of sodium carbonate.

[0039] The preparation method of the concrete anti-cracking reinforced self-repairing material described in this embodiment is the same as that described in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com