Electrolytic machining method for maintaining and remanufacturing of aeroengine

An aero-engine and processing method technology, which is applied to manufacturing tools, electrochemical processing equipment, metal processing equipment, etc., can solve the problems of difficult processing, large removal allowance, large size, etc., so as to reduce economic costs and reduce processing. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

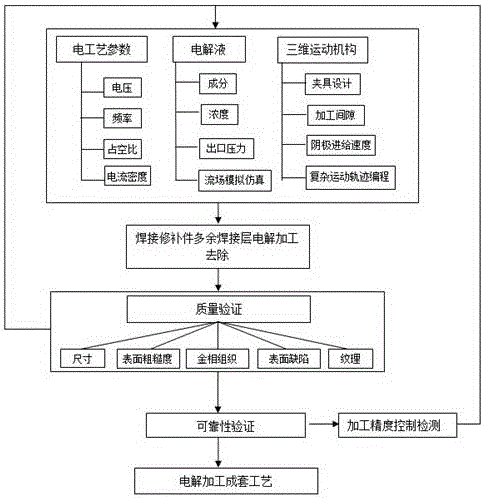

[0055] Such as figure 1 Shown, a kind of electrolytic machining method of aero-engine maintenance and remanufacturing, it comprises:

[0056] 1. Research on electrolytic machining mechanism of titanium alloy

[0057] (1) Basic rules of electrochemical machining: machining speed and its influencing factors, surface quality and its influencing factors, machining accuracy and its influencing factors;

[0058] (2) Research on metal passivation of workpieces: research on the formation of passivation state, partial destruction of passivation state, pinhole corrosion, and properties of passivation film;

[0059] 2. Design and development of cathode

[0060] (1) Electroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com