Blast furnace online small-bore micro-damage furnace hearth side wall temperature detection method

A detection method and a technology with small aperture, applied in thermometers, thermometers with directly sensitive electrical/magnetic components, measuring devices, etc., can solve problems such as inability to maintain and replace, and achieve simple construction, small equipment investment, and maintenance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

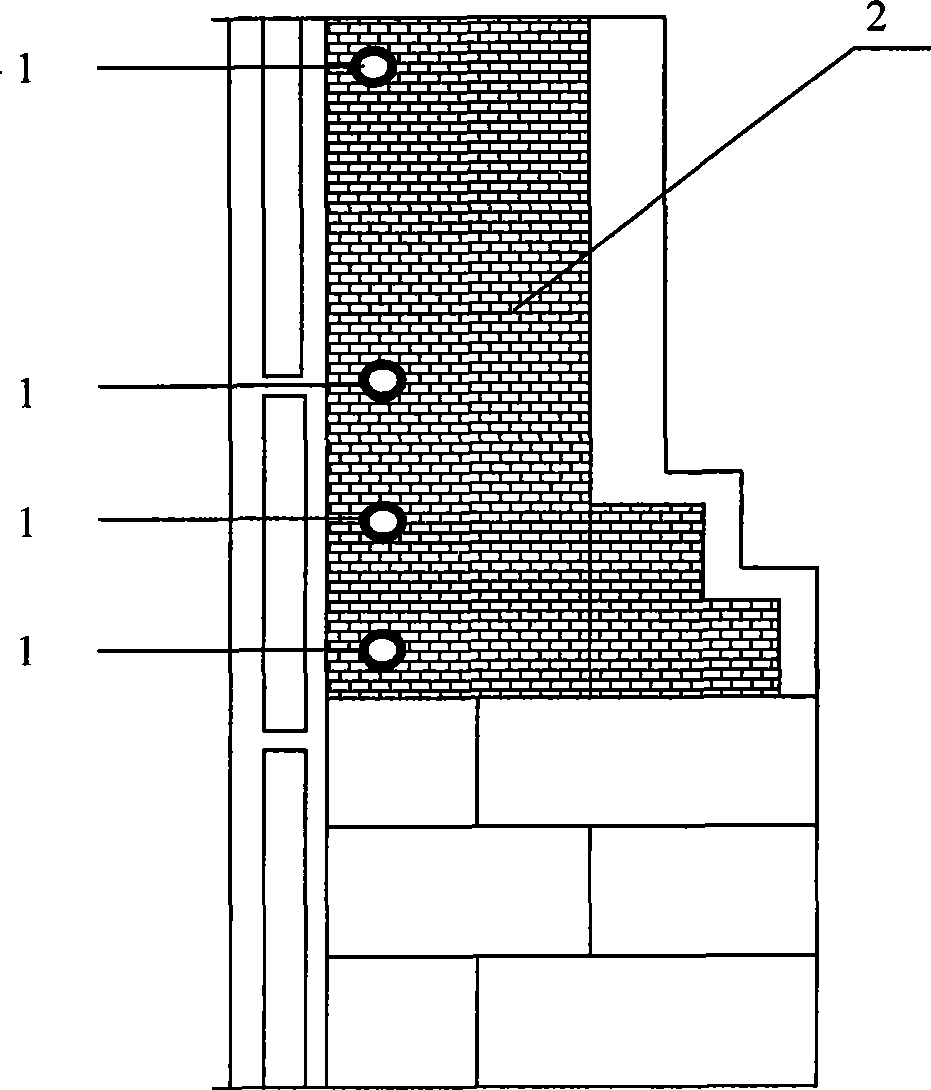

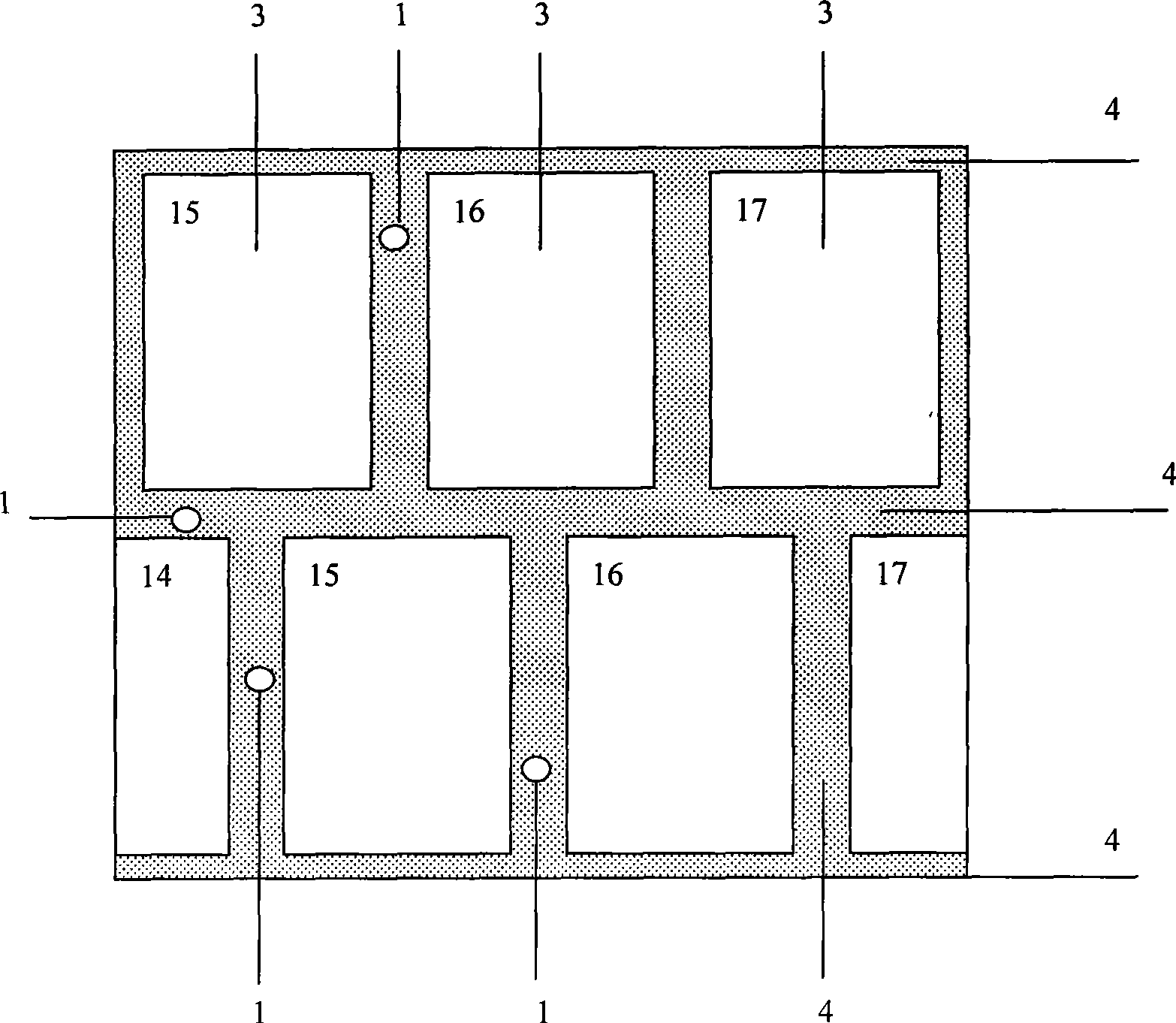

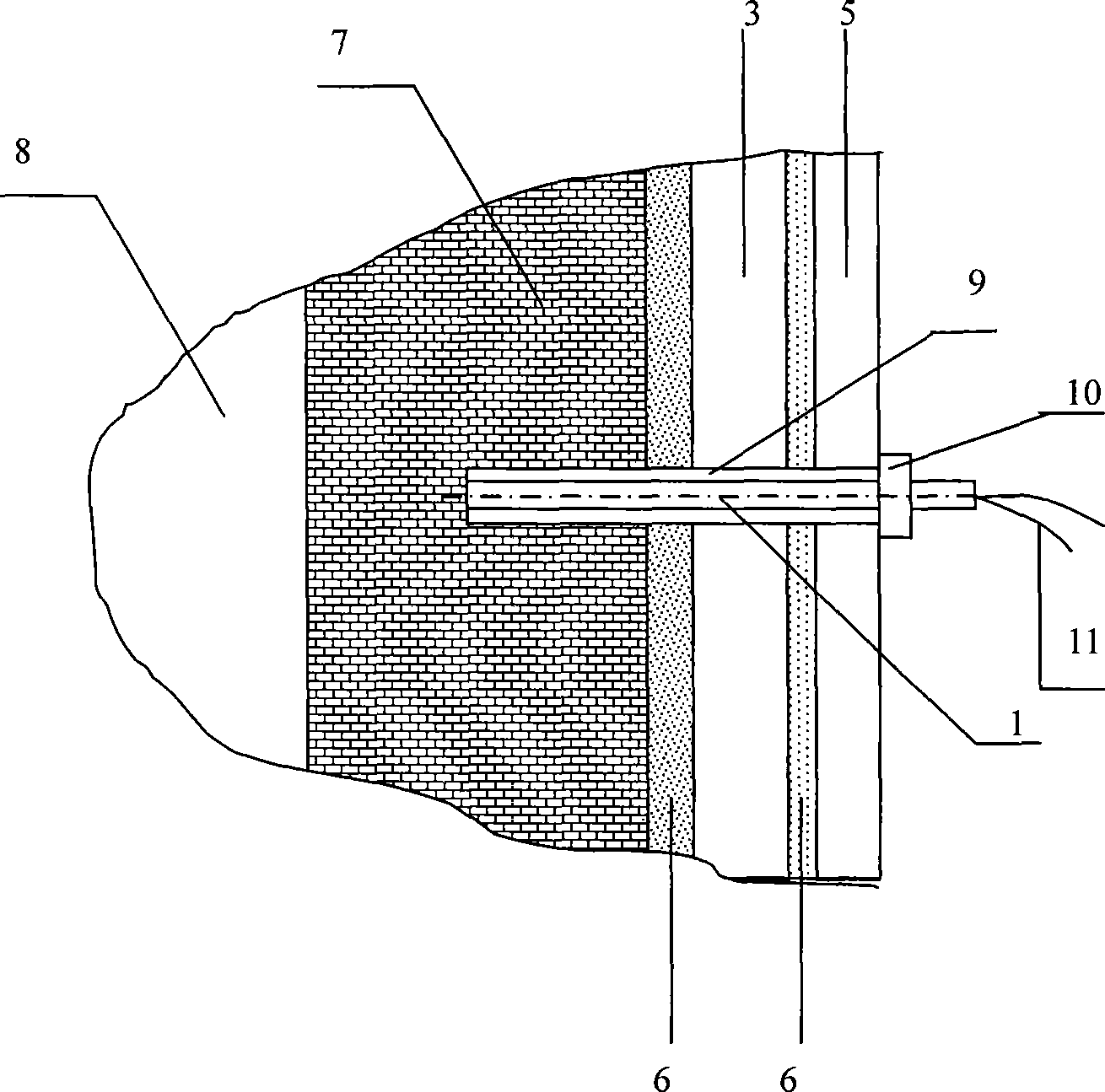

[0023] An online small-aperture micro-damage hearth side wall temperature detection method for a blast furnace, such as figure 1 , figure 2 and image 3 As shown, the detection method is as follows:

[0024] Such as figure 1 As shown, the furnace hearth 2 to be tested is composed of furnace skin 5, stave 3 and carbon brick 7 from outside to inside, between furnace skin 5 and stave 3, between stave 3 and carbon brick 7, grouting material and The ramming material is filled. The grouting material is anhydrous pressure injection mud, and the ramming material is graphite carbon ramming material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com