Device for detecting damage depth of object surface scratch

A technology for detecting equipment and object surfaces, applied in the field of measurement, to achieve the effects of simple operation, small size and convenient reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

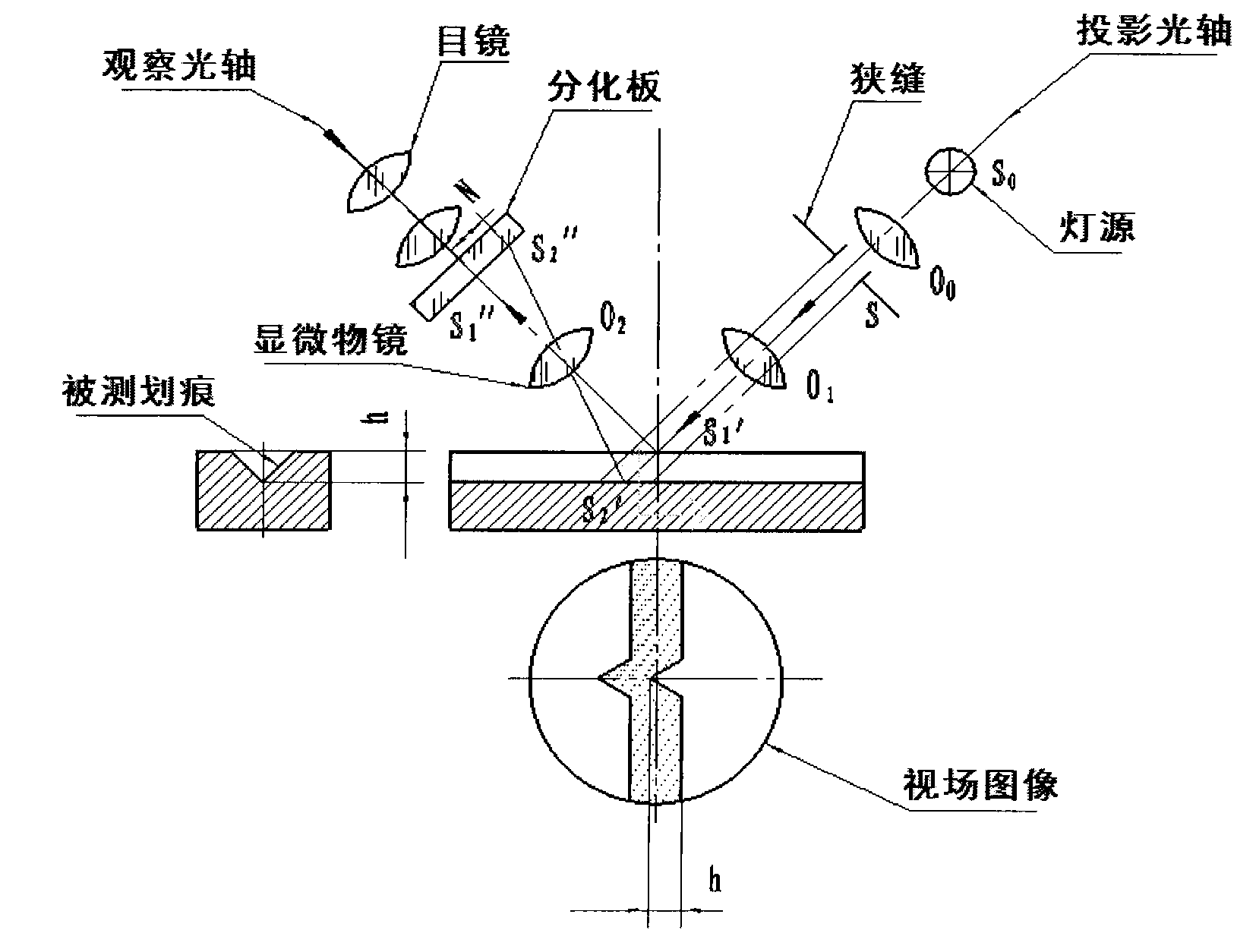

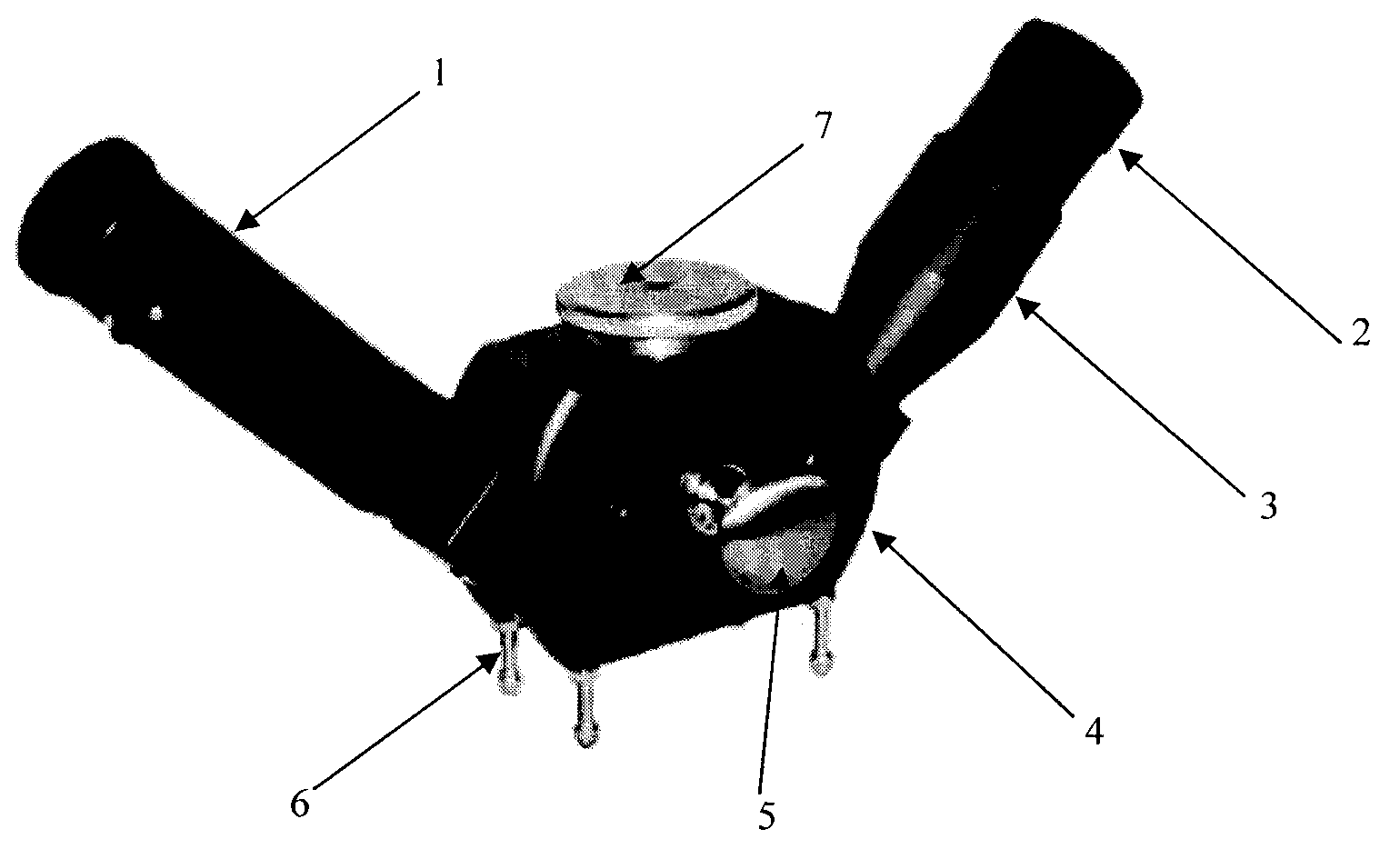

[0038] This embodiment is to use the detection device of the present invention for the detection of the depth of scratches on the surface of a military aircraft cockpit. It works in the eyepiece observation mode, and its optical measurement principle diagram is as follows figure 1 As shown, the light source S0 is placed in the projection light mirror O 0 on the focus, by S 0 The light emitted by O 0 Finally, a beam of parallel light is obtained, and the parallel light passes through the slit S to form a narrow parallel beam; the beam is projected through the objective lens O 1 Convergence, projected onto the measured surface of the part in a 45° direction to form a light section; the existence of scratches makes the measured surface of the part have tiny peaks and valleys, and the peak is in S 1 ′ point produces reflection, and the trough is at S 2 ' produces reflections (where S 1 'The point is exactly O 1 and O 2 common focus), then the reflected light passes through t...

Embodiment 2

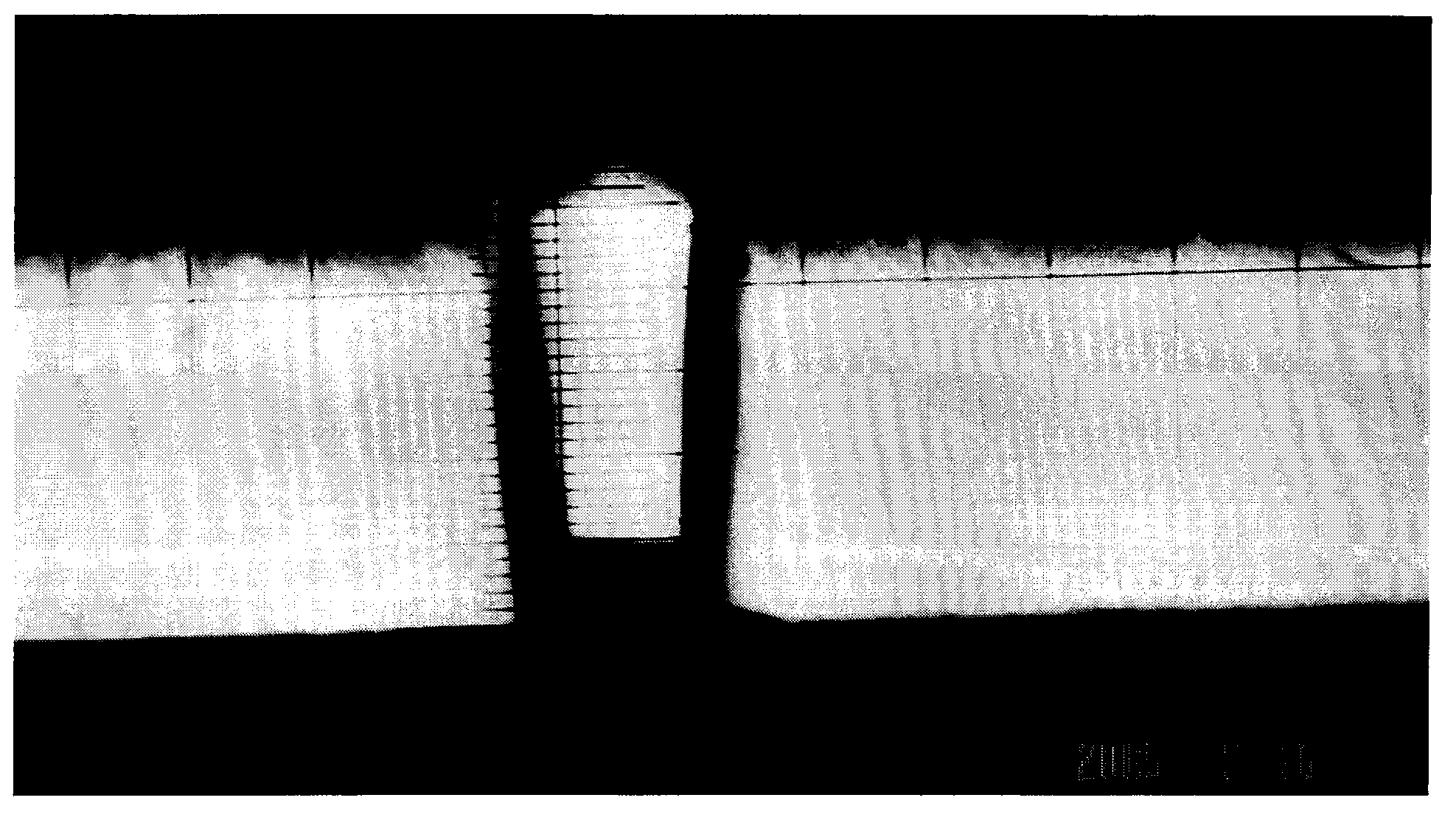

[0044] This embodiment is that the detection equipment of the present invention is used for a kind of military aircraft skin surface scratch depth detection, works under the CCD observation mode, and its optical schematic diagram is as follows Figure 4 As shown, the light source S 0 placed in the projection light mirror O 0 on the focus, by S 0 The light emitted by O 0 Finally, a beam of parallel light is obtained, and the parallel light passes through the slit S to form a narrow parallel beam; the beam is projected through the objective lens O 1 Convergence, projected onto the measured surface of the part in a 45° direction to form a light section; the existence of scratches makes the measured surface of the part have tiny peaks and valleys, and the peak is in S 1 ′ point produces reflection, and the trough is at S 2 ' produces reflections (where S 1 'The point is exactly O 1 and O 2 common focus), then the reflected light passes through the observation objective lens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com