Rear tong head clamping mechanism of micro-damage screwing machine

A technology of clamping mechanism and twisting machine, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of increasing oil field workload and cost, damage of pipe string surface, pipe string corrosion, etc., and achieve economic benefits Considerable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

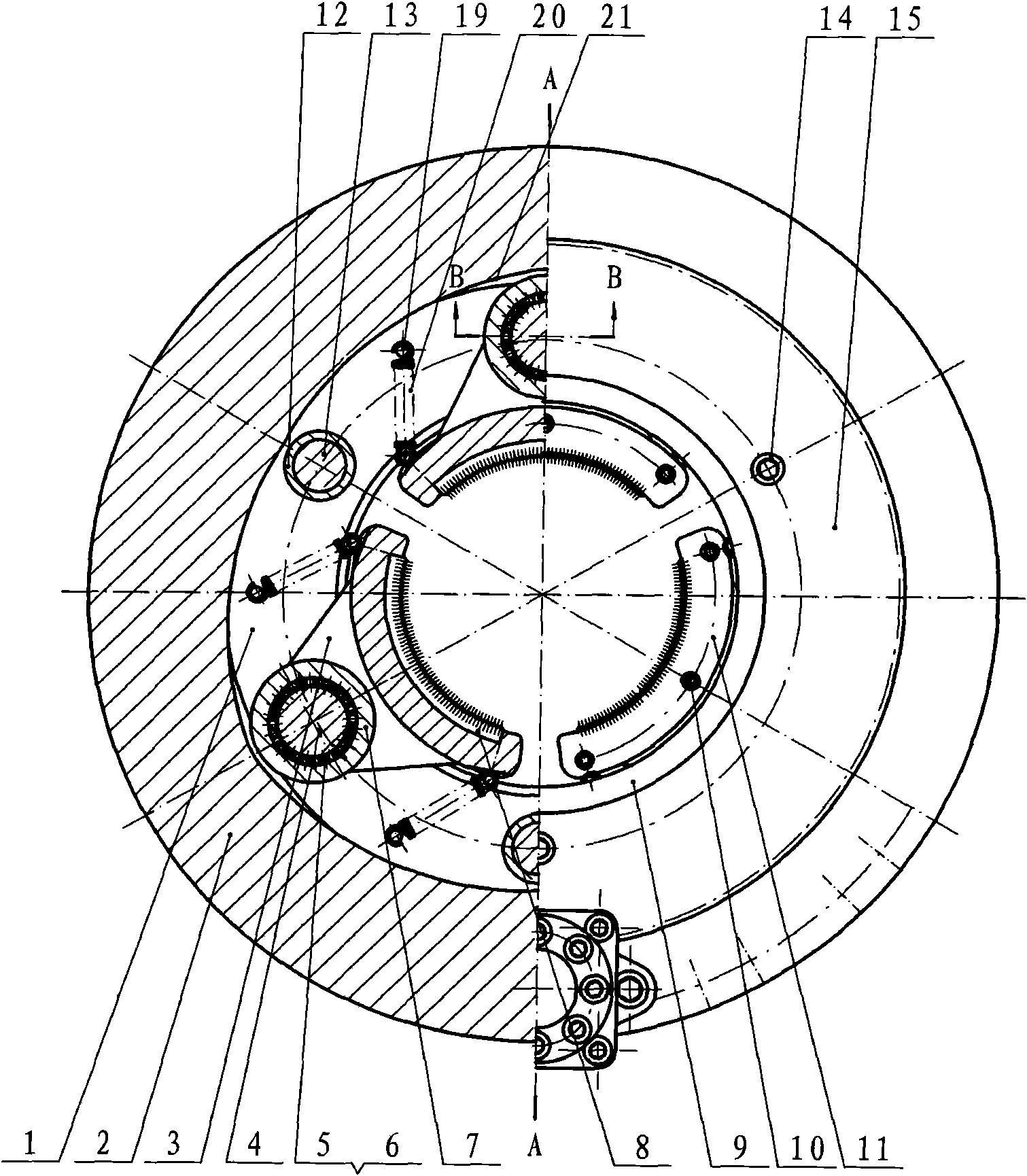

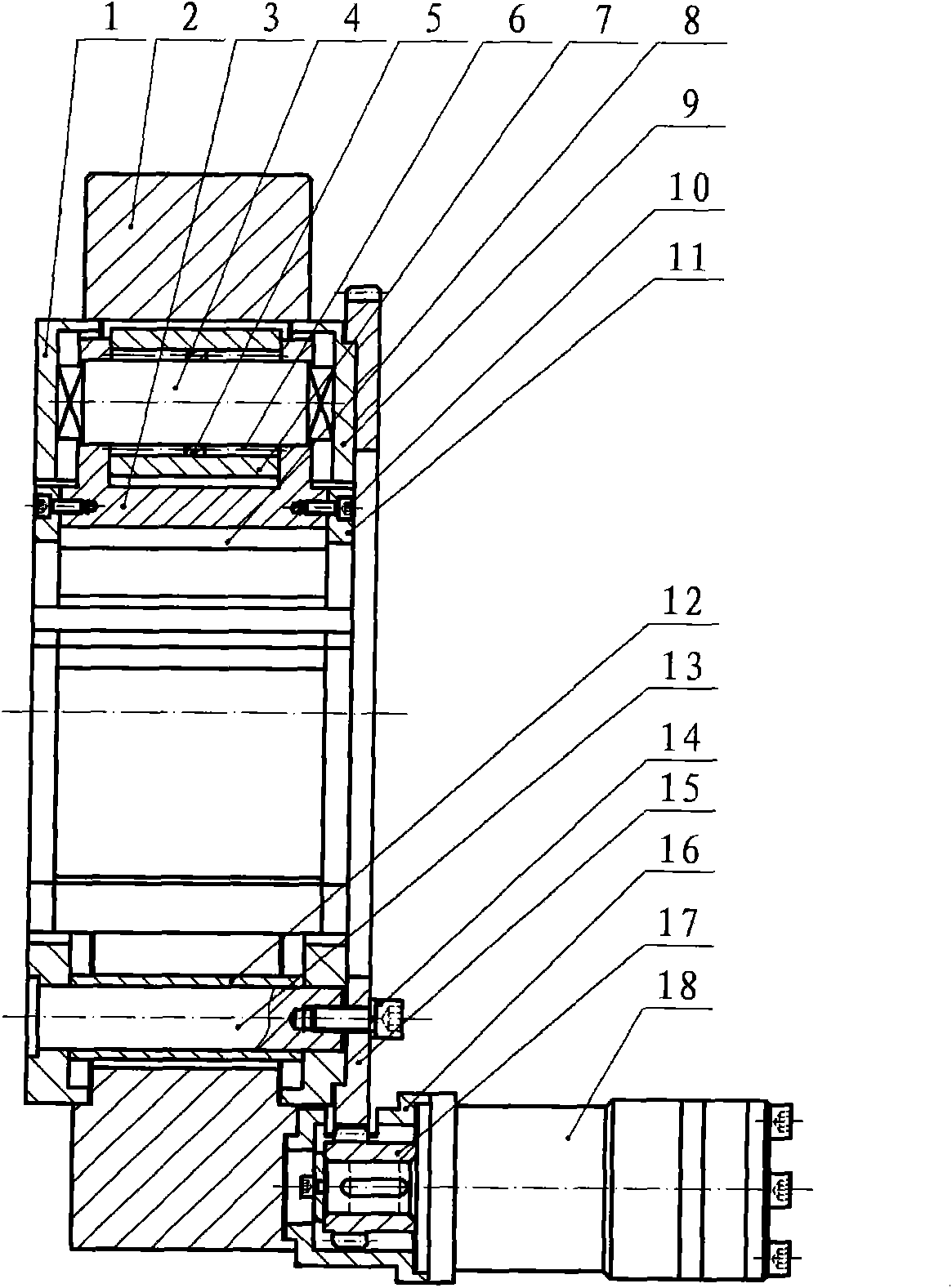

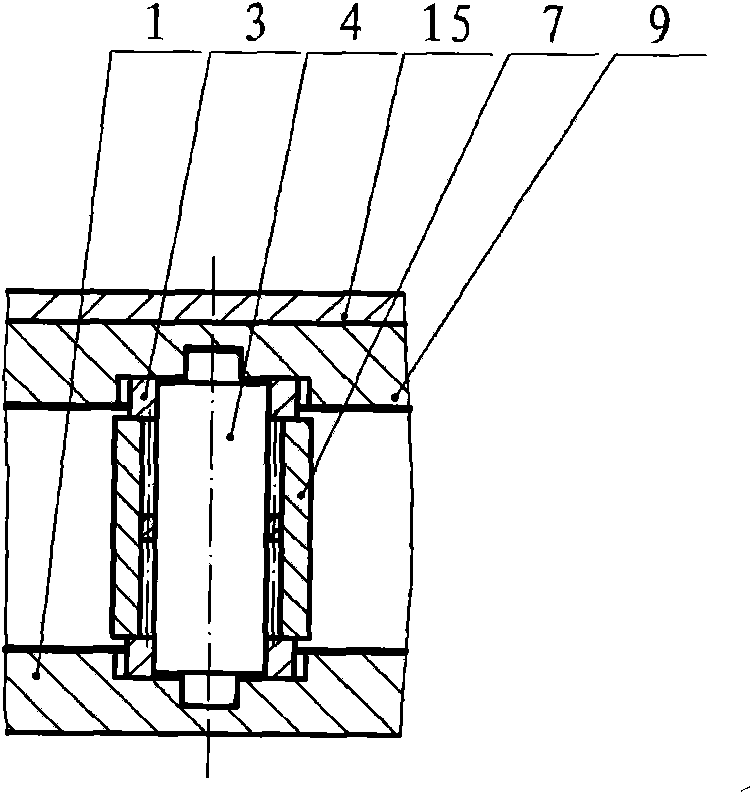

[0012] in figure 1 , 2 In, a micro-damage screwing machine back pliers clamp head clamping mechanism consists of the lower jaw frame 1, the back clamp head body 2, the jaw plate 3, the roller shaft 4, the bearing spacer 5, the needle bearing 6, the roller 7, the tooth Block 8, upper jaw frame 9, screw 10, stop 11, fixed sleeve 12, fixed shaft 13, screw 14, back clamp head gear ring 15, motor seat 16, motor gear 17, hydraulic motor 18, pin shaft 19, The return spring 20 and the working arc 21 are composed. A working arc 21 is provided on the inner curved surface of the back pliers head main body 2, and the working arc 21 is directly processed on the back pliers head main body 2, or on an additional ramp. Three or more jaw plates 3 are arranged in the main body 2 of the back pliers head. The jaw plate 3 is equipped with a roller shaft 4, a roller 7, a tooth block 8 and a return spring 20. The roller shaft 4 is installed in the shaft hole of the jaw plate 3, the roller 7 is strin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com