Ethylene-propylene-diene monomer composite elastomer and preparation method thereof

A technology of EPDM and elastomer, which is applied in the field of EPDM composite elastomer and its preparation, can solve the problem that the relationship between molecular structure and damping performance has not been fully established, high damping mechanical properties are not easy to balance, and the damping mechanism cannot be explained Clarity and other issues to achieve the effect of enhancing strength and toughness, improving damping performance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) 36g EPDM (100phr), 0.72g MAH (2phr), 0.018g initiator Add 101 (0.05phr) and 0.8g St (nSt=nMAH) into the preheated torque rheometer in a certain order, knead for 8 minutes under the processing conditions of 170°C and 60rpm, and discharge to obtain the graft MAH-g-EPDM, denoted as mEPDM 0 (MAH grafting rate 1.18%).

[0032] (2) the mEPDM of step (1) 0 , antioxidant 1010 (mEPDM 0 0.3wt.%), different amounts of 3-amino-1,2,4-triazole (ATA), add the preheated torque rheometer according to the formula ratio in Table 1 and a certain order, at 160 ℃, 50rpm Mixing under the conditions for 20 minutes, respectively, to obtain ATA functionalized EPDM mEPDM 0 -xATA (x=molar ratio n ATA :n MAH ) series samples.

[0033] Table 1

[0034]

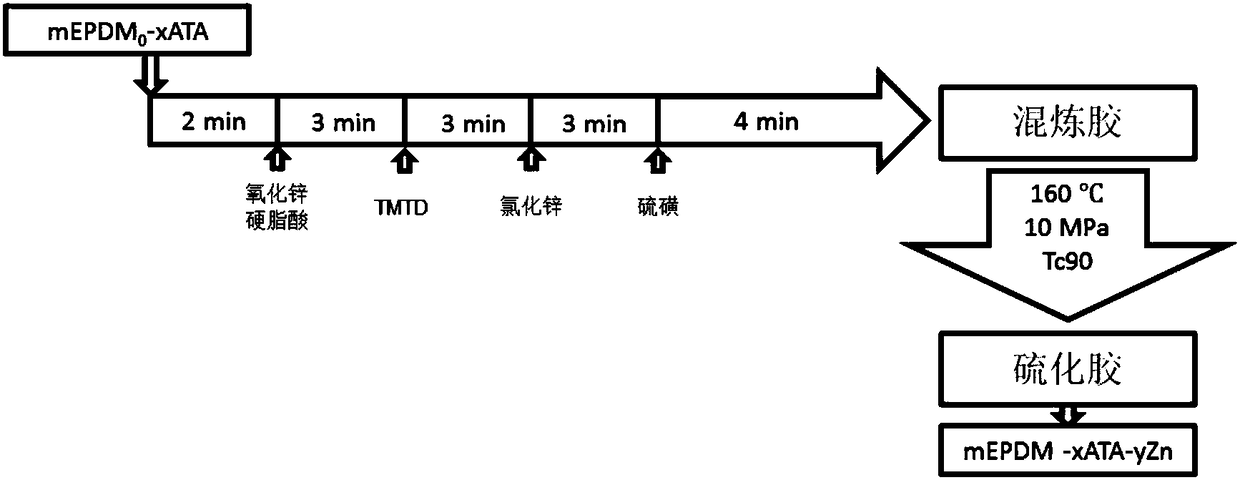

[0035] (3) Use an open mill to mix mEPDM 0 -ATA(n ATA :n MAH =1) 100phr, 5phr of zinc oxide, 1phr of stearic acid, 1.5phr of TMTD, different amounts of zinc chloride, 1.5phr of sulfur are added according to the formula ratio in Ta...

Embodiment 2

[0041] Step (1) and step (2) are the same as embodiment 1.

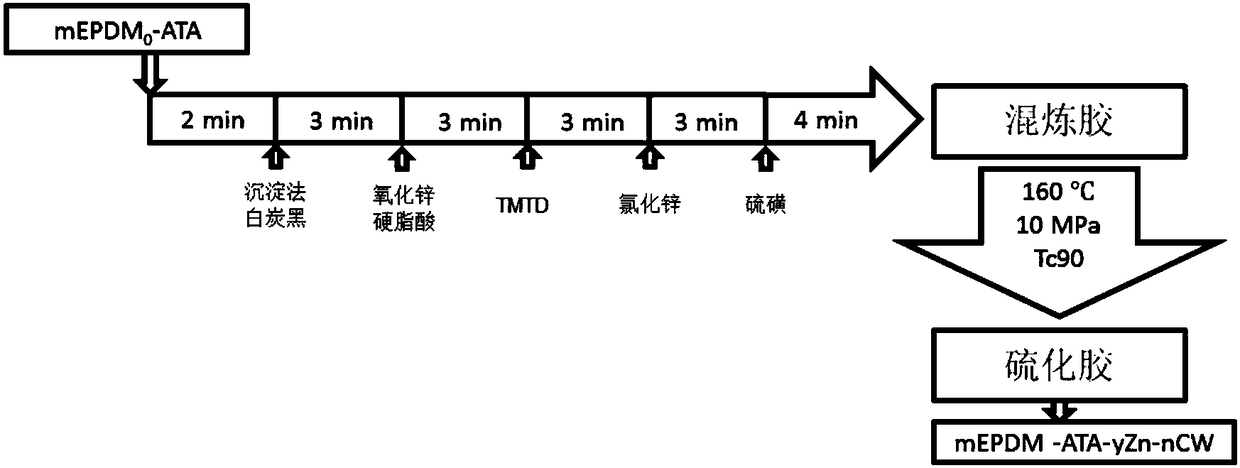

[0042] (3) Use an open mill to mix mEPDM 0 -ATA(n ATA :n MAH =1) 100phr, different amounts of precipitated silica (n phrCW) 10 / 20phr, zinc oxide 5phr, stearic acid 1phr, TMTD1.5phr, zinc chloride (nZn:nMAH=y; y=0.4), sulfur 1.5 The phr is fed in a certain order, and the materials are mixed evenly by using the inclined knife method, and the triangular bag is made, rolled, and the film is produced after six times of thinning, and the mEPDM is prepared. 0 -ATA-yZn-nCW series rubber compound. The rubber was parked for 12 hours, and vulcanized on a flat vulcanizing machine at 160°C and 10MPa pressure. The vulcanization time was Tc90, and mEPDM-ATA-yZn-nCW series elastomers were obtained, and mEPDM-ATA-0.4Zn-10CW was recorded as sample 3 .

[0043] The preparation process of mEPDM-ATA-yZn-nCW vulcanizate in this embodiment is shown in figure 2 .

Embodiment 3

[0045] Step (1) and step (2) are the same as embodiment 1.

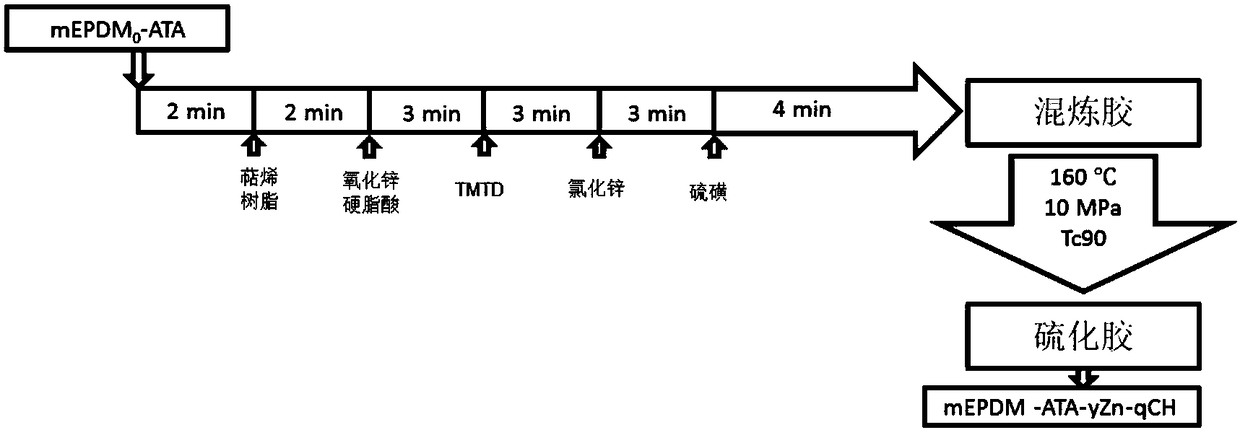

[0046] (3) Use an open mill to mix mEPDM 0 -ATA (nATA:nMAH=1) 100phr, different amounts of terpene resin (q phrCH) 2 / 8 / 16 / 32phr, zinc oxide 5phr, stearic acid 1phr, TMTD1.5phr, zinc chloride (nZn:nMAH=y ; y=0.4), sulfur 1.5phr are fed in a certain order, use the oblique knife method to mix the materials evenly, make triangular bags, rub rolls, thin pass six times and then go out, and prepare mEPDM 0 -ATA-yZn-qCH series rubber compound. The rubber was parked for 12 hours, and vulcanized on a flat vulcanizing machine at 160°C and 10MPa pressure. The vulcanization time was Tc90, and mEPDM-ATA-yZn-qCH series elastomers were obtained, and mEPDM-ATA-0.4Zn-32CH was recorded as sample 4 .

[0047] For the preparation process of mEPDM-ATA-yZn-qCH vulcanizate in this example, see image 3 .

[0048] The results of the cyclic loading and unloading test of samples 1 to 4 obtained in the above examples and the comparison sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com