Bionic self-repairing concrete and preparation method thereof

A concrete, self-healing technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of restricted diffusion, reduction of concrete strength, concrete strength damage, etc., and achieves highly ordered pore structure, uniform pore size distribution, The effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of Mesoporous Bioactive Glass Microspheres

[0028] The preparation of mesoporous bioactive glass microspheres by template method specifically includes the following steps:

[0029] (1) The triblock copolymer Pluronic F127 (molecular formula is EO 106 PO 70 EO 106 , EO is ethylene oxide, PO is propylene oxide; average molecular weight 12600) is dissolved in the mixed solvent (the volume ratio of absolute alcohol and glacial acetic acid is 5:2) that absolute ethanol and glacial acetic acid form, described The mixing ratio of Pluronic F127 and mixed solvent is 1g:25mL, stir and mix well to obtain mixed solution A.

[0030] (2) Add 100g of the oxide precursor mixture to 400g of the mixed solution A obtained in step (1), stir and dissolve to obtain the mixed solution B, the oxide precursor mixture is composed of 51.19g calcium nitrate tetrahydrate, 18.33g normal Methyl silicate, 27.11g aluminum nitrate nonahydrate, 3.37g trimethyl phosphate, the mi...

Embodiment 2

[0032] Example 2 Preparation of Mesoporous Bioactive Glass Composite Microspheres

[0033] The preparation of mesoporous bioactive glass composite microspheres comprises the following steps:

[0034] (1) Inoculate the aerobic type alkali-resistant Bacillus (Bacillus cohnii DSM 6307) on the medium (each liter of medium contains 4.5g peptone, 30g maltodextrin, 10g ammonium chloride, 2g sodium citrate, 1g magnesium sulfate, The balance is water, the pH value is 9-10), shake culture at room temperature for 72 hours to obtain the bacterial liquid, centrifuge the bacterial liquid at 4000r / min for 20min to obtain the bacterial sludge, and resuspend the bacterial sludge with the culture medium to obtain The concentration is (4~5)×10 7 Bacteria liquid of each / mL; Mesoporous bioactive glass microspheres (prepared in Example 1) and the bacterium liquid are impregnated according to the ratio of 1g:2.5mL by vacuum impregnation method, and dried at 35°C to obtain internal loads with Mesop...

Embodiment 3

[0036] Embodiment 3 preparation of calcium peroxide microspheres

[0037] The preparation of calcium peroxide microspheres comprises the following steps: polybutylene succinate is dissolved in chloroform to make a solution with a mass fraction of 5%, and then evenly sprayed on the surface of calcium peroxide to make polybutylene succinate The thickness of the film layer of the glycol ester is 20nm, vacuum drying and recovery of chloroform to obtain calcium peroxide microspheres.

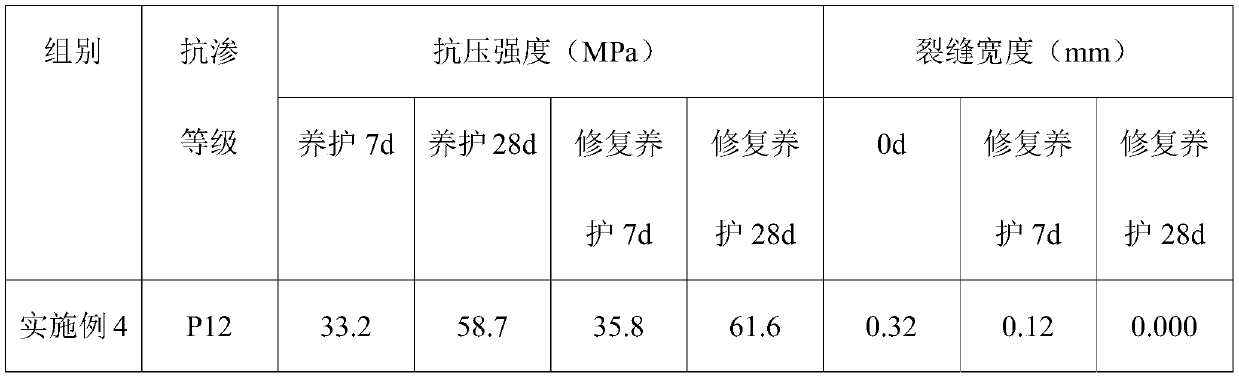

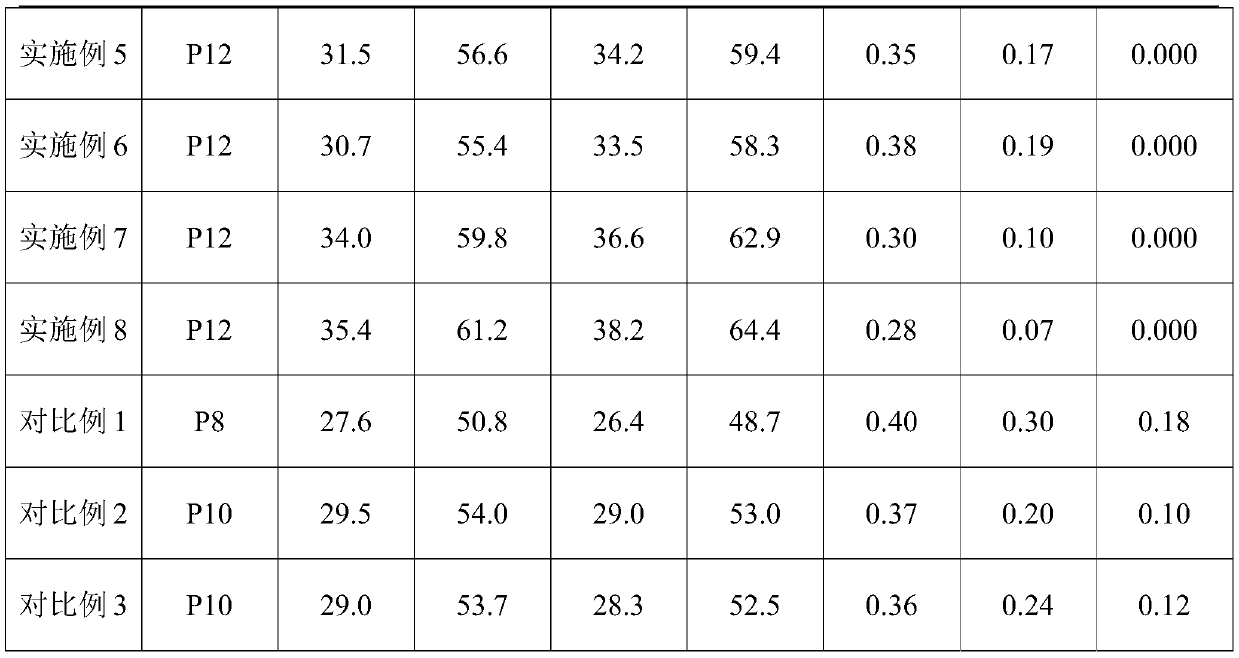

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com