SF6 high-voltage circuit breaker polytetrafluoroethylene composite material nozzle and preparation method thereof

A technology of polytetrafluoroethylene and high-voltage circuit breakers, which is applied in the field of high-voltage circuit breaker nozzles, can solve problems such as rough surface and turbulent flow of arc extinguishing gas, and achieve the effect of prolonging service life and slowing down ablation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

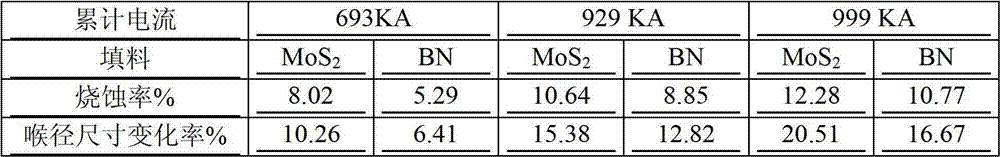

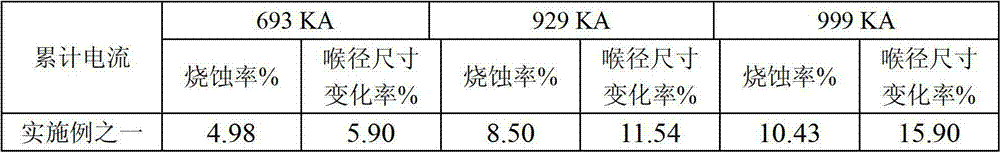

[0022] The arc ablation resistant SF of the present invention 6 A preparation method for a polytetrafluoroethylene composite spout of a high-voltage circuit breaker (see Table 2 for examples 1 to 4), comprising the following steps:

[0023] First, the PTFE powder with a particle size of 5-20 μm is mixed evenly with the BN powder with a particle size of 1-10 μm in a certain proportion, and then the above mixture is mixed with the MoS powder with a particle size of 1-10 μm. 2 Mix evenly; the amount of BN added is controlled in PTFE powder, BN powder and MoS 2 1~8% of the total mass of powder; MoS 2 The amount of addition is controlled in PTFE powder, BN powder and MoS 2 The total mass of the powder is 0.1-0.4%, and the final mixture is molded and sintered to make a nozzle blank (the molding and sintering process is the same as the process for preparing a BN-PTFE composite nozzle in the prior art).

[0024] Table 2: Examples 1-4 (ingredient ratio by mass percentage)

[0025] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com