Nonlinear ultrasonic guided wave detection method and device for pipeline micro damage

A non-linear ultrasonic and detection method technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve complex signal processing problems, achieve high sensitivity, reduce instrument nonlinear interference, and ensure stable pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

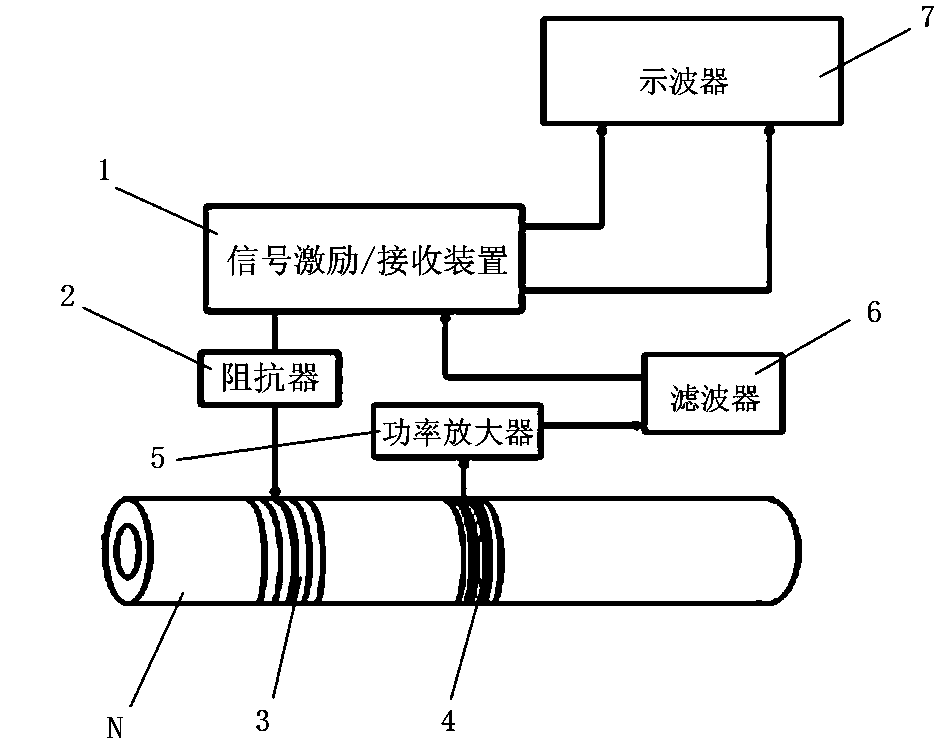

[0029] Example: see Figure 1 to Figure 3 A non-linear ultrasonic guided wave detection device for pipeline micro-damage, comprising an excitation / reception unit 1 for ultrasonic guided wave signals, an impedance device 2, an excitation transducer 3, a receiving transducer 4, and a receiving preamplifier (power amplifier 5), filter 6, oscilloscope 7, in which the excitation / reception unit 1 of the signal excites an ultrasonic signal of a certain frequency, passes through the impedance 2 to reduce noise and connects the developed excitation transducer 3 to the tested specimen N through the coupling agent , the other end of the test piece is connected to the receiving transducer 4 to detect the propagated guided wave signal, and after being filtered by the amplifier 5, it is sent to the oscilloscope 7, and the signal is averaged 1000 times in the oscilloscope 7 to improve the signal-to-noise ratio. storage. The stored signals are further analyzed on the oscilloscope 7, or analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com