A magnetic memory detection device of oil drill rod micro-crack

An oil drill pipe and detection device technology, applied in the direction of material magnetic variables, etc., can solve the problems of high detection cost, damage detection probe, large detection blind area, etc., and achieve the effects of low lift-off effect, high sensitivity and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the present invention will be described in detail below with reference to the drawings and specific examples.

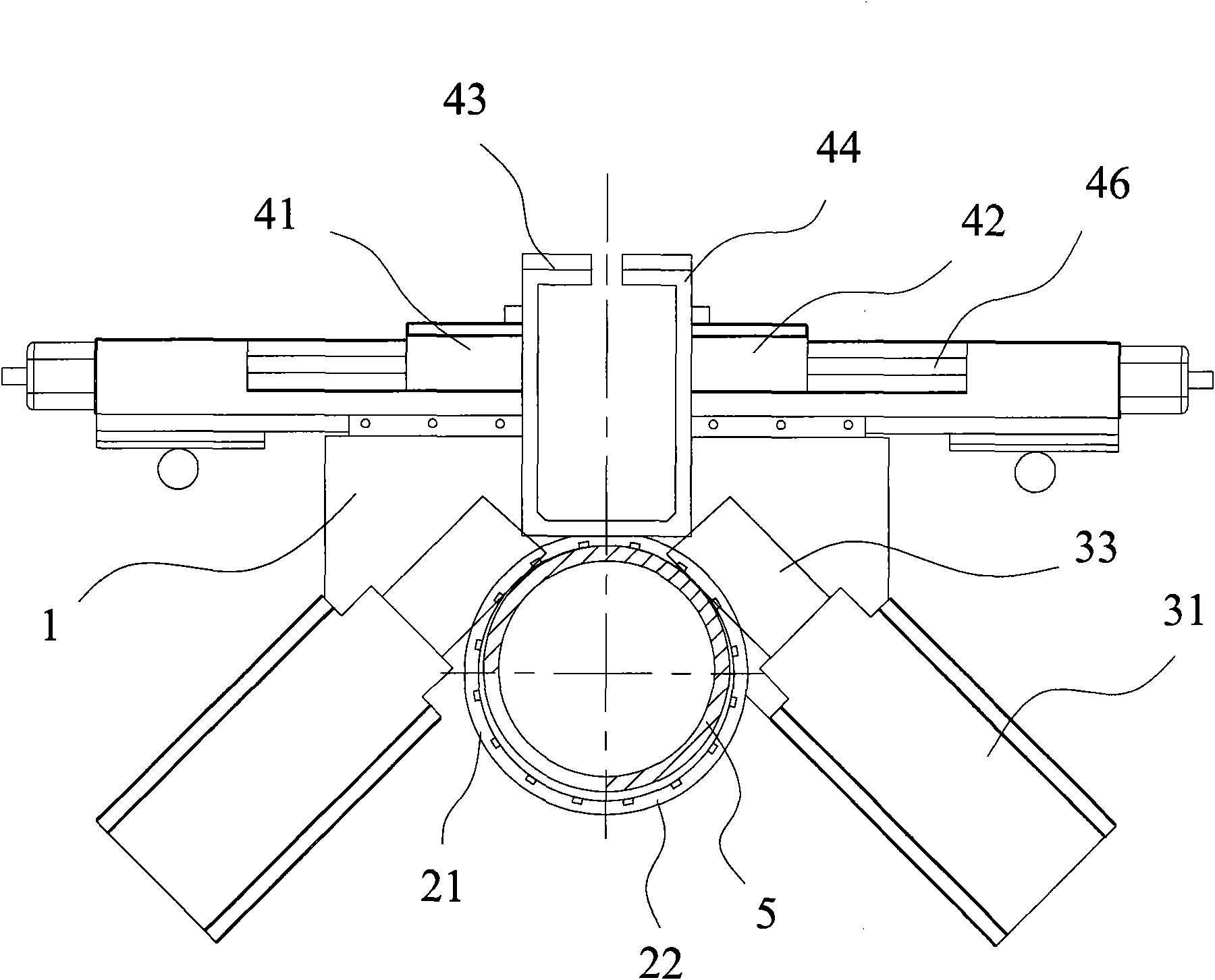

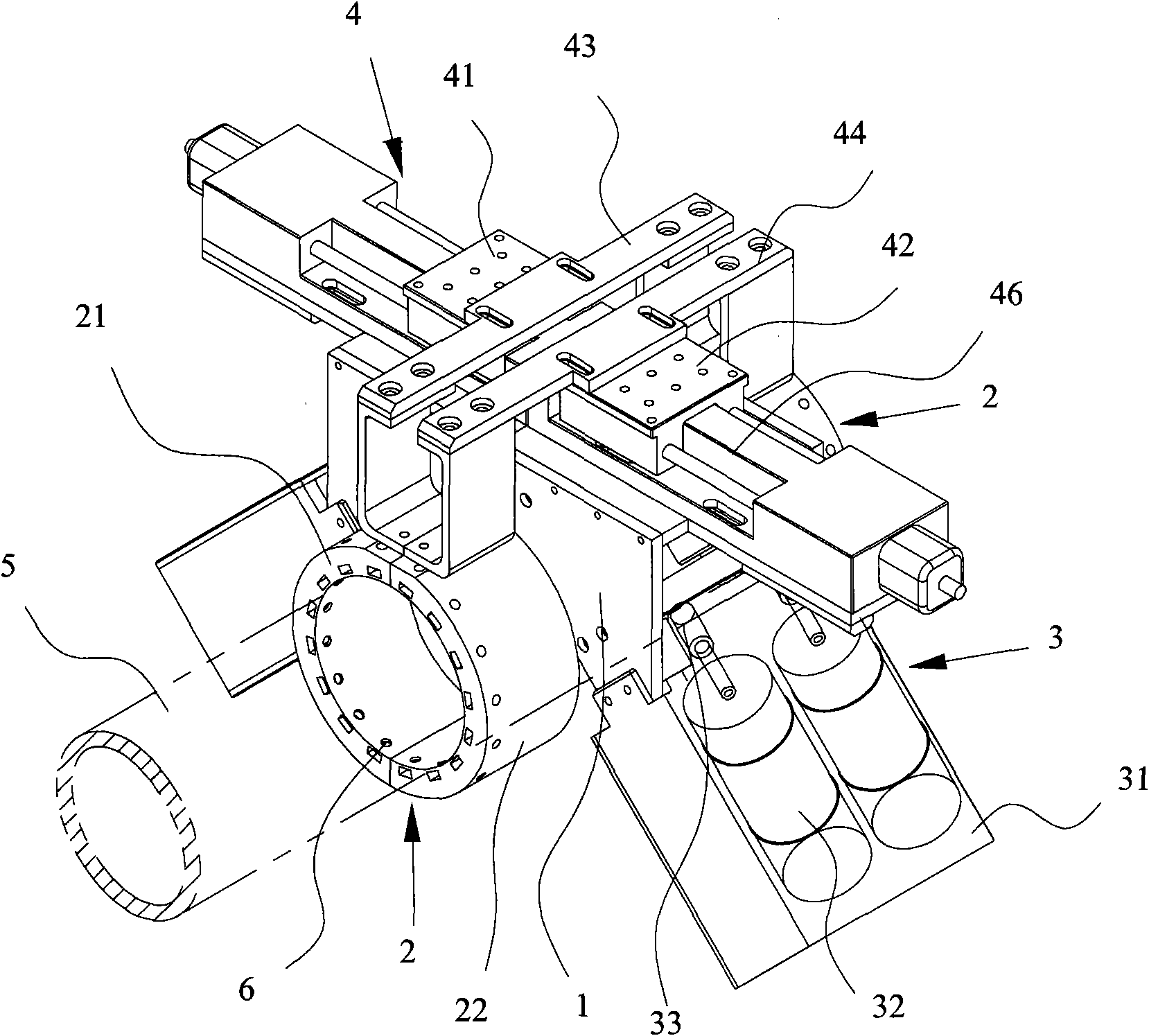

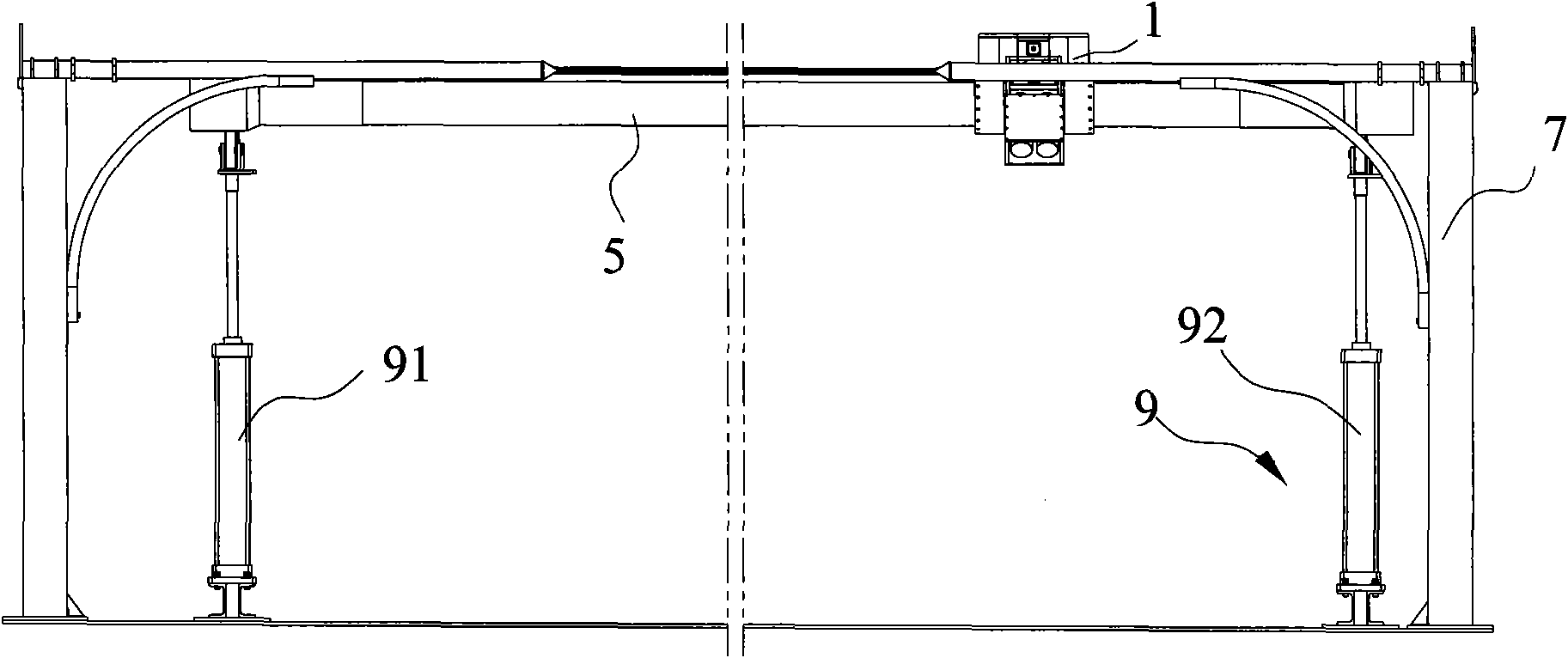

[0025] Such as figure 1 , 2 As shown, the magnetic memory detection device of the present invention includes: a frame 1 and a detection ring 2, two detection rings 2, the detection ring 2 can be sleeved on the drill pipe 5, and the two detection rings 2 are respectively composed of two half-rings 21 . Of course, it is also possible to fan out or move laterally apart in order to open the two half-rings 21 , 22 . The two detection rings 2 are provided with magnetic memory sensors 6 for detecting the drill pipe 5. In this embodiment, the two detection rings 2 are respectively provided with 16 magnetic memory sensors 6 along the circumferential direction, so that the detection can be ensured in the There is no blind area in the circumferential direction; the frame 1 is also provided with a first drive device 3 for driving the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com