Infrared thermal imaging detection method for thermal barrier anti-ablation coating defects

A technology of infrared thermal imaging and detection method, which is applied in the direction of material defect testing, etc., can solve the problems that the original thermal image sequence cannot be effectively collected and complete, the quantitative detection and evaluation of coating quality cannot be realized, and the heat transfer cannot be realized, so as to achieve non-destructive The effect of detection, strong operability and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

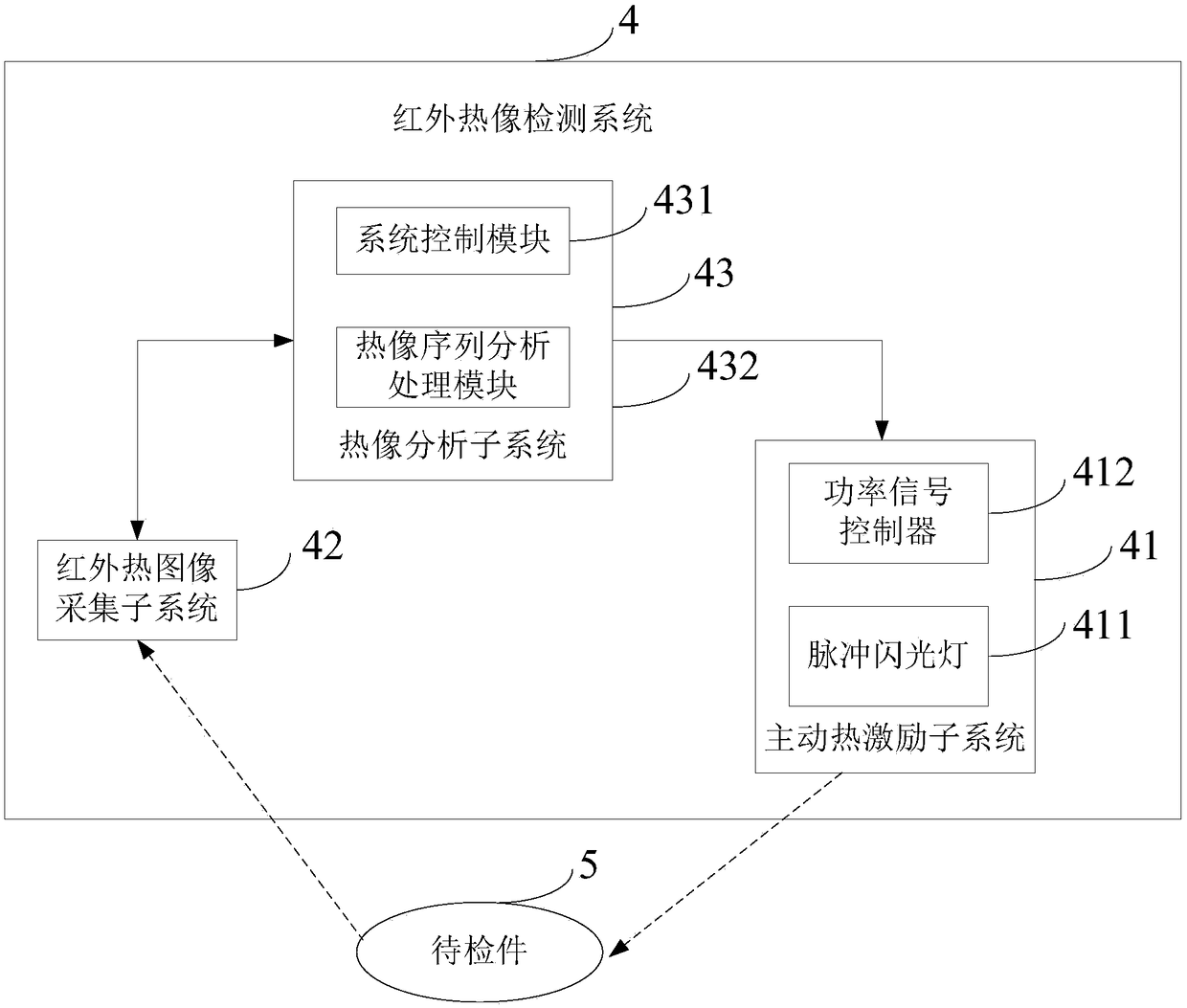

[0026] In application, the thermal barrier anti-ablation coating 2 is disposed on the outer surface of the substrate 3 , and when the structure of the thermal barrier anti-ablation coating 2 is a multilayer structure, each layer is sequentially arranged from the outer surface of the substrate 3 outward. exist figure 1 In the figure, the shown thermal barrier anti-ablation coating 2 is disposed on the upper surface of the substrate 3, including the first layer 21, the second layer 22, the third layer 23 and the fourth layer 24 from bottom to top, a total of 4 layers , that is, the structure of the thermal barrier anti-ablation coating is a 4-layer structure. The material of the matrix 3 may be metal, or non-metallic carbon fiber compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com