Measuring device and method for measuring the deviation angle between the normal line of the light-transmitting surface of an electro-optic crystal and the z-axis

An electro-optic crystal and measurement device technology, applied in the field of optical detection, can solve problems such as scratch measurement errors, and achieve the effects of high measurement accuracy and good measurement repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

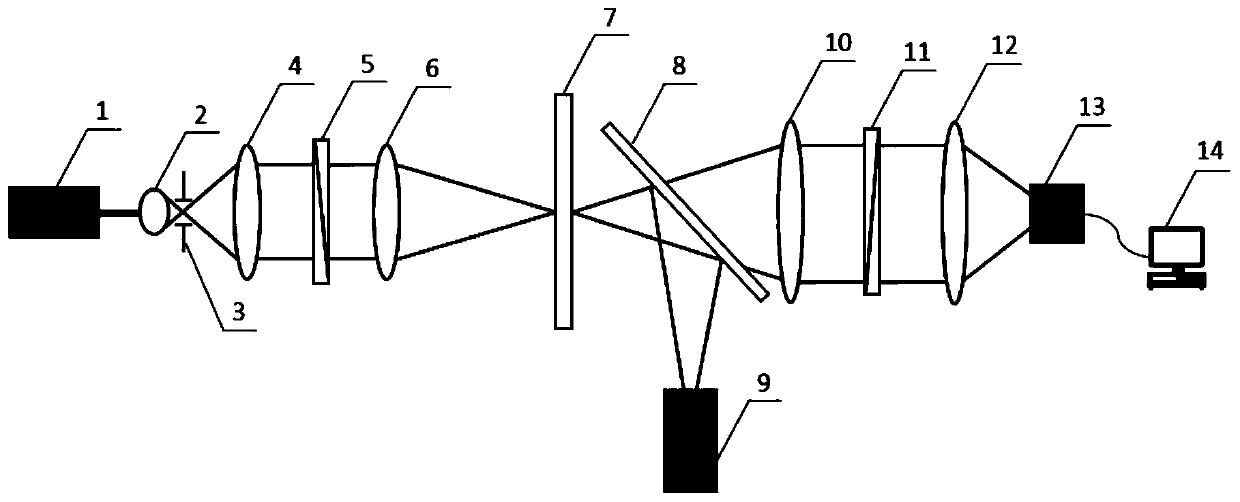

[0024] figure 1 It is a schematic diagram of the experimental device of the present invention. It can be seen from the figure that the measuring device for the deviation angle between the normal line of the light-passing surface of the electro-optic crystal and the Z-axis of the present invention includes: a laser 1, a first lens 2, a spatial filter 3, a second lens 4, a Polarizer 5, third lens 6, electro-optic crystal to be tested 7, beam splitter 8, digital photoelectric inner focusing autocollimator 9, fourth lens 10, analyzer 11, imaging lens 12, detector 13 and computer processing System 14;

[0025] The direction of the laser light emitted from the laser 1 is the first lens 2, the spatial filter 3, the second lens 4, the polarizer 5, the third lens 6 and the beam splitter 8; the input laser passes through the The beam splitter 8 is divided into reflected light and transmitted light, and the digital photoelectric internal focusing autocollimator 9 is arranged in the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com