Online real-time monitoring method and system for structural damage

A real-time monitoring system, a technology for structural damage, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems such as ablation and affecting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] In order to achieve the above purpose, an embodiment of the present invention provides an online real-time monitoring method for structural damage, the online real-time monitoring method for structural damage is applied to a high-speed sliding electrical contact slide rail; the high-speed sliding electrical contact slide rail includes a high-speed sliding electrical contact pressure plate , a slide block and a slide rail, the slide rail is arranged in the high-speed sliding electrical contact pressure plate; the slide block slides in the slide rail.

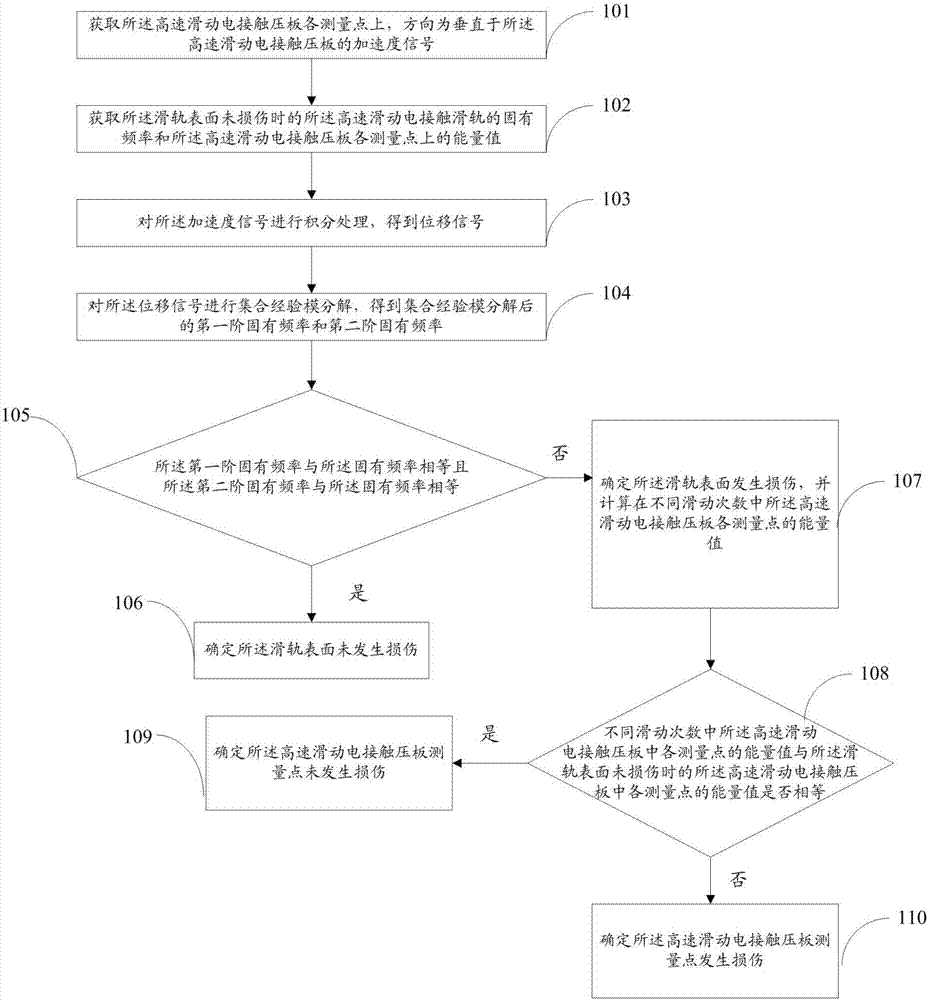

[0071] figure 1 It is a schematic flow chart of an online real-time monitoring method for structural damage in an embodiment of the present invention, as figure 1 As shown, the online real-time monitoring method for structural damage provided by the embodiment of the present invention specifically includes the following steps:

[0072] Step 101: Obtain acceleration signals at each measurement point of the high-speed slidi...

Embodiment 2

[0151] In order to verify that the method provided in the first embodiment can monitor the transient micro-damage of the structure in real time, the second embodiment of the present invention is used for verification below.

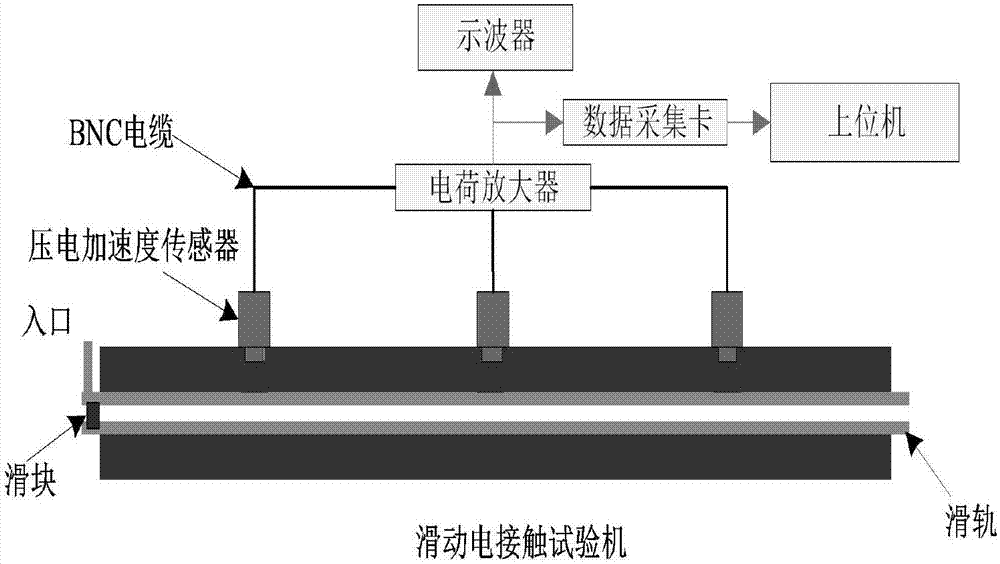

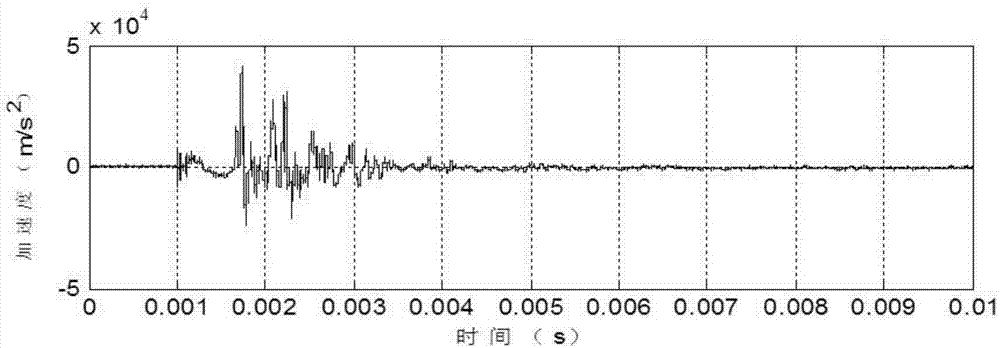

[0152] figure 2 It is a schematic structural diagram of a high-speed sliding electrical contact slide rail testing machine according to an embodiment of the present invention; image 3 It is a schematic diagram of the acceleration signal changing with time according to the embodiment of the present invention; Figure 4 It is a schematic diagram of the variation of the displacement signal with time according to the embodiment of the present invention; Figure 5 It is a comparison chart of the acceleration self-power spectral density of the embodiment of the present invention; Figure 6 It is a comparison chart of acceleration spectrum energy values in an embodiment of the present invention; Figure 7 It is a comparison chart of the self-power spectra...

Embodiment 3

[0164] In order to achieve the above-mentioned purpose, the present invention also provides a micro-damage on the track surface generated during the high-speed sliding process with a large current carrying capacity, an online damage identification and positioning system for the electrical contact track surface in the transient process under the background of multi-field coupling, namely this The invention provides an online real-time monitoring system for structural damage, which can realize online identification and positioning of transient micro damage to structures under high-frequency and high-speed background conditions.

[0165] Figure 8 It is a structural schematic diagram of an online real-time monitoring system for structural damage in an embodiment of the present invention, as Figure 8 As shown, the online real-time monitoring system for structural damage includes:

[0166] The acceleration signal acquisition module 801 is used to acquire the acceleration signal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com