Sticky protein hydrogel and preparation method thereof

A hydrogel and protein technology, applied in the field of viscous and tough protein hydrogel and its preparation, can solve problems such as toughness and strength, and achieve good biocompatibility and non-toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

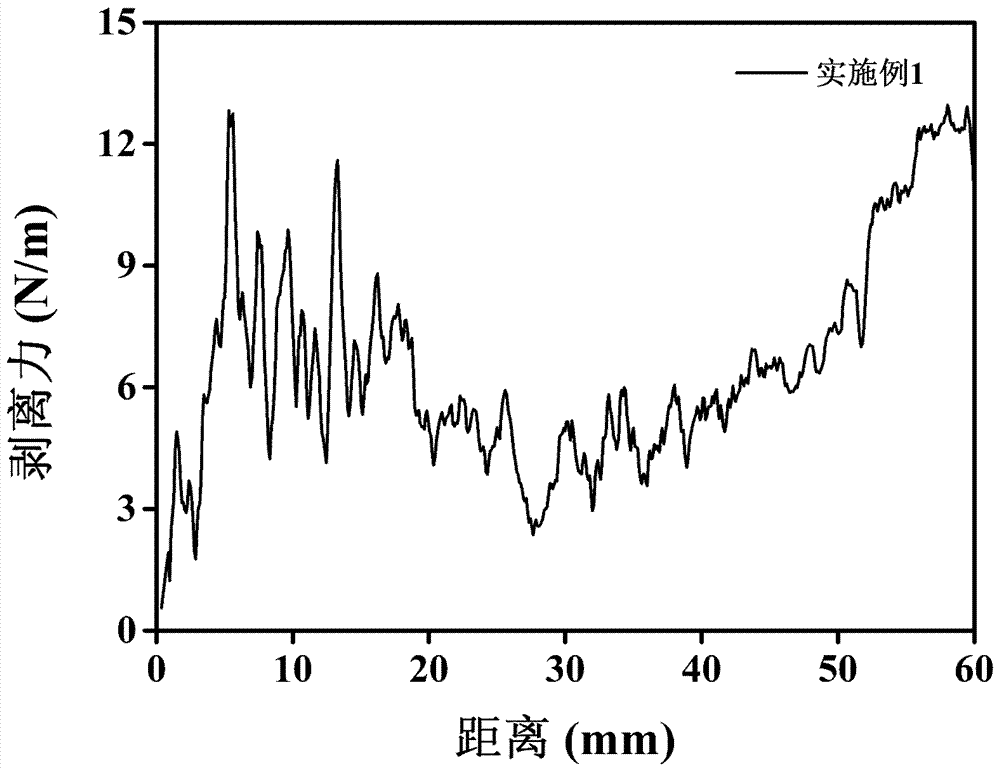

Embodiment 1

[0023] Embodiment 1: The steps and conditions of a method for preparing a viscous and tough protein hydrogel are as follows:

[0024] (1) Dissolution of casein

[0025] Dissolve 9g of casein in 60mL of deionized water to prepare a casein solution with a mass concentration of 1.5g / mL. At this time, the casein is insoluble in water. Use a 10M sodium hydroxide solution to adjust the pH to 6.6 and use a disperser to fully Stir for 30 minutes until completely dissolved, then put it in an ultrasonic cleaner for 1 hour to remove air bubbles, and obtain an aqueous solution of casein, and put the solution in a refrigerator at 4°C for later use;

[0026] (2) Preparation of hydrogel

[0027] Add 0 mL (corresponding to 0 g of casein weight) aqueous casein solution, 3.5 g of acrylamide, 0.0175 g of N,N-methylenebisacrylamide and 0.02 g of potassium persulfate into 10 mL of deionized water, and stir at room temperature until completely Dissolve, and finally add 0.0156g tetramethylethylene...

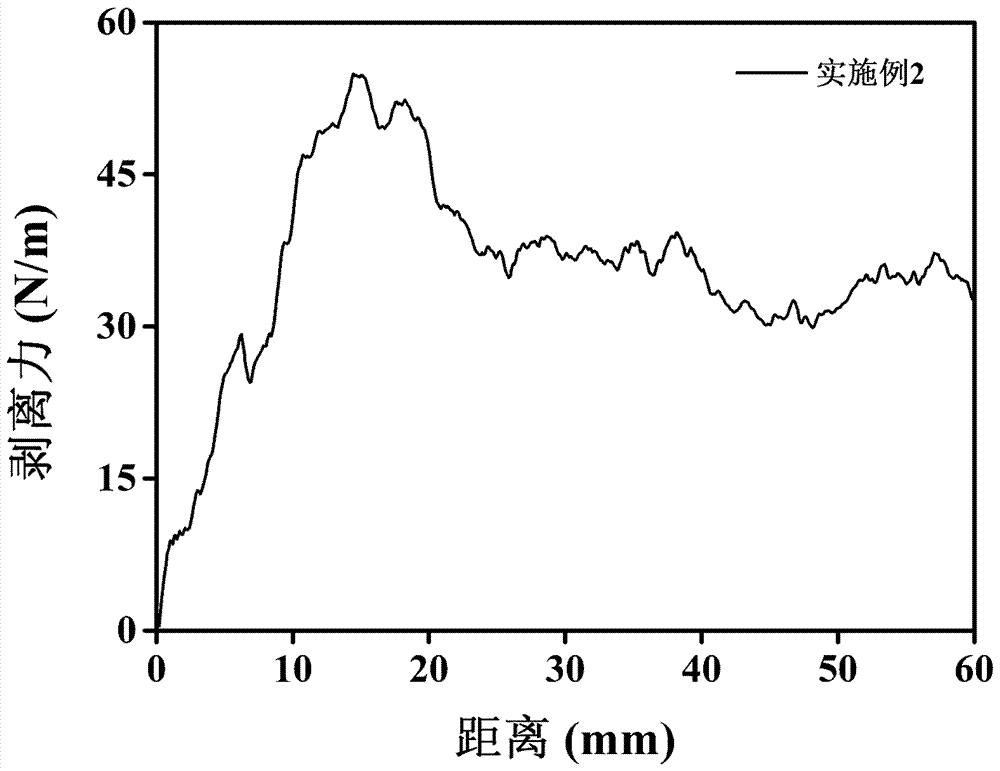

Embodiment 2

[0030] Embodiment 2: The steps and conditions of a method for preparing a viscous and tough protein hydrogel are as follows:

[0031] (1) Dissolution of casein

[0032] Dissolve 9g of casein in 60mL of deionized water to prepare a casein solution with a mass concentration of 1.5g / mL. At this time, the casein is insoluble in water. Use a 10M sodium hydroxide solution to adjust the pH to 6.8 and use a disperser to fully Stir for 40 minutes until completely dissolved, then put it into an ultrasonic cleaner for 1.5 hours to remove air bubbles, and obtain an aqueous solution of casein, put the solution in a refrigerator at 4°C and refrigerate it for later use;

[0033] (2) Preparation of hydrogel

[0034] Add 1.67mL (corresponding to 0.5g of casein weight) aqueous casein solution, 3g of acrylamide, 0.015g of N,N-methylenebisacrylamide and 0.02g of potassium persulfate into 8.33mL of deionized water, and stir at room temperature Until it is completely dissolved, finally add 0.0156...

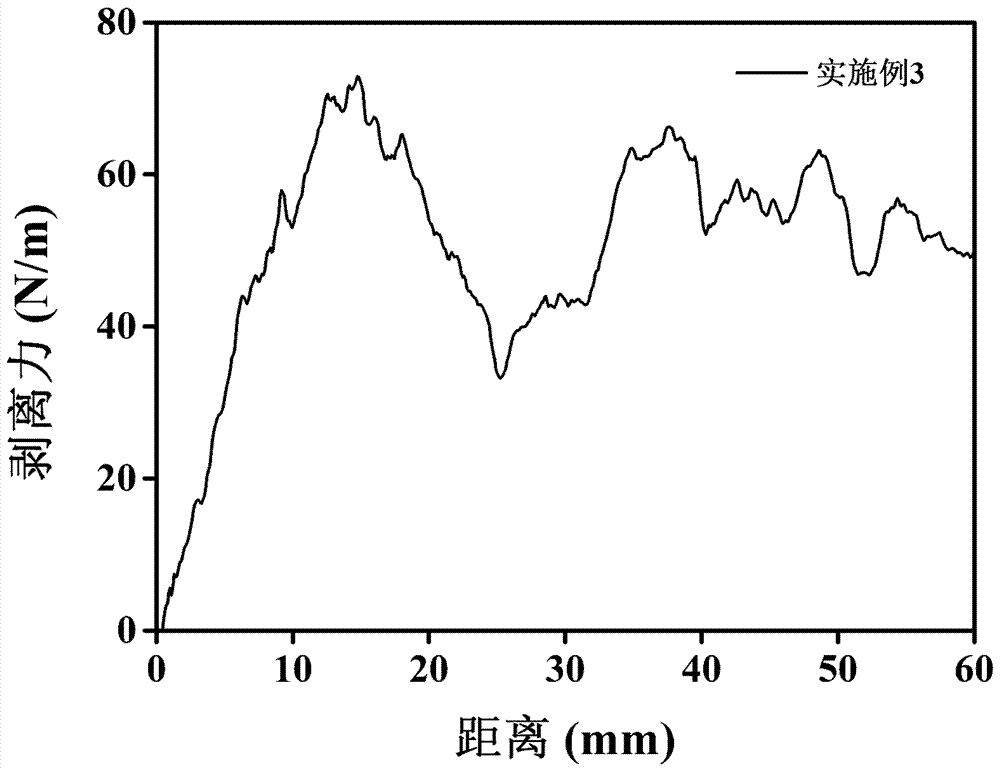

Embodiment 3

[0036]Embodiment 3: The steps and conditions of a method for preparing a viscous and tough protein hydrogel are as follows:

[0037] (1) Dissolution of casein

[0038] Dissolve 9g of casein in 60mL of deionized water to prepare a casein solution with a mass concentration of 1.5g / mL. At this time, the casein is insoluble in water. Adjust the pH to 7.0 with a 10M sodium hydroxide solution and use a disperser to fully Stir for 50 minutes until completely dissolved, then put it into an ultrasonic cleaner for 1.5 hours to remove air bubbles, and obtain an aqueous solution of casein, put the solution in a refrigerator at 4°C and refrigerate for later use;

[0039] (2) Preparation of hydrogel

[0040] Add 3.33mL (corresponding to 1g of casein) aqueous solution of casein, 2.5g of acrylamide, 0.0125g of N,N-methylenebisacrylamide and 0.02g of potassium persulfate into 6.67mL of deionized water, and stir at room temperature Until it is completely dissolved, finally add 0.0156g of tetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel force | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com