Bionic flexible dry electrode and manufacturing method thereof

A manufacturing method and technology of dry electrodes, which are used in medical science, sensors, diagnostic recording/measurement, etc., can solve problems such as poor contact, monitoring of electrode discomfort, and large size of dry electrodes, and achieve outstanding performance, increased fit, and structure. clever effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

[0031] Preparation of PDMS molds:

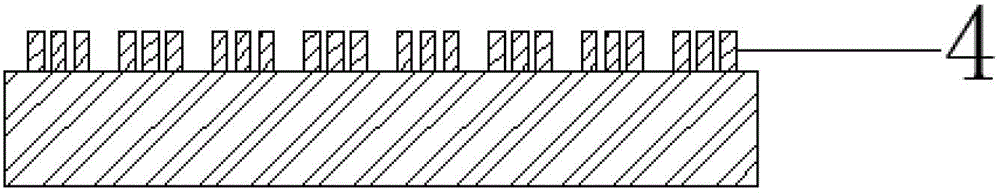

[0032] Clean the silicon wafer with oxygen plasma, and form an oxide layer on the silicon wafer by CVD; spin-coat positive photoresist on the silicon wafer oxide layer, expose, develop, and pattern the photoresist layer; use CF4 reactive ion etching on the silicon wafer The places not covered with photoresist form the second level structure 4 of the mold. Such as Figure 1a shown.

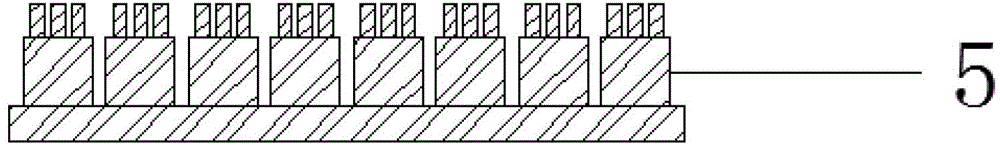

[0033] Clean off residual photoresist. Spin-coat positive photoresist on the silicon wafer, expose, develop, and pattern the photoresist layer; use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com