Resin anchoring agent for initiation system

A technology of resin anchoring agent and initiation system, which is applied in the field of resin anchoring agent, can solve problems such as difficult to achieve, harsh reaction conditions, incomplete curing, etc., and achieve the effect of wide adjustment range and high curing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

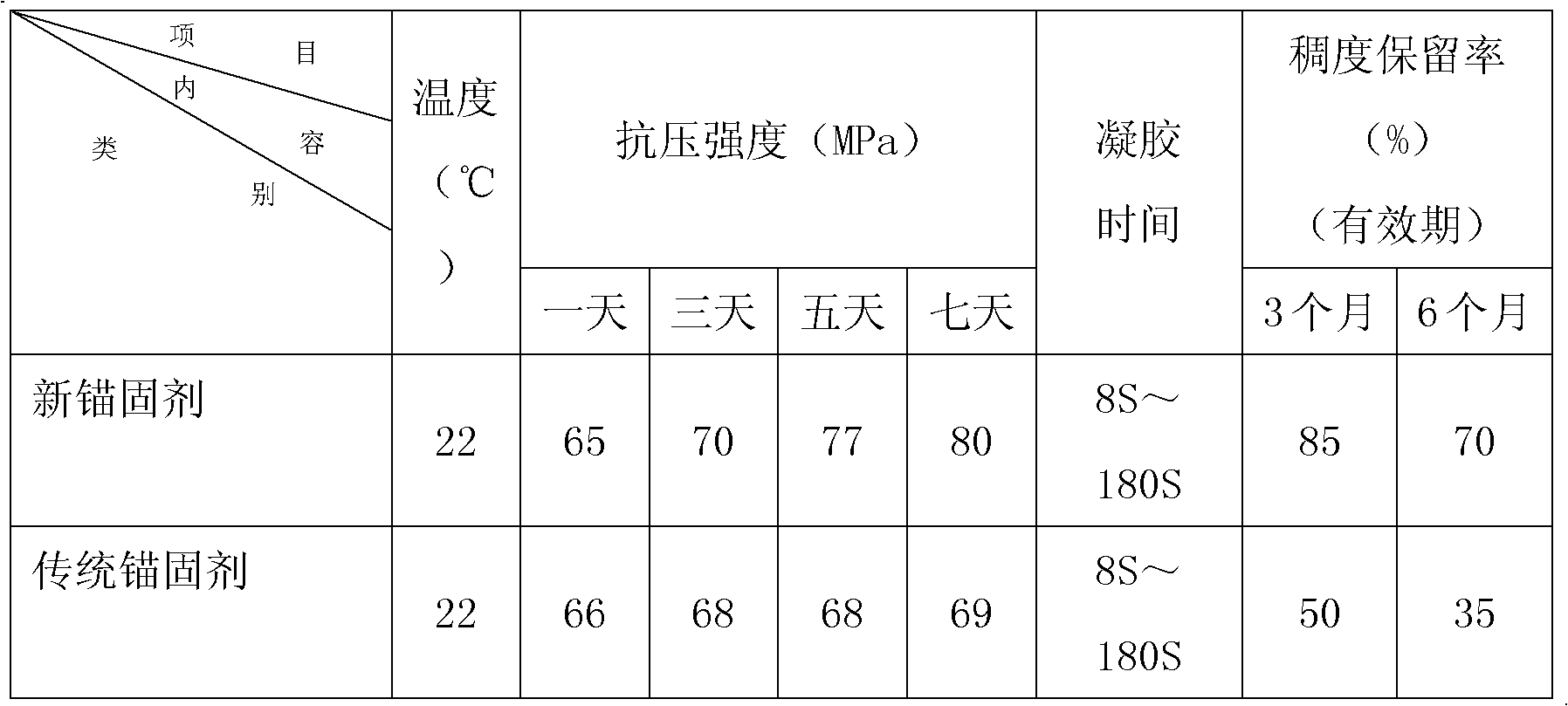

Embodiment 1

[0028] The raw material ratio of the new accelerated initiation system resin anchoring agent with a gel time of 8S to 180S in terms of mass fraction is:

[0029] Clay part:

[0030] 100 parts of unsaturated polyester resin

[0031] Cobalt octanoate or cobalt naphthenate 0.2 to 4 parts

[0032] Dimethylaniline 0~2 parts

[0033] Fumed white carbon black 0~3 parts

[0034] Inorganic filler A 300~600 parts

[0035] Curing agent part:

[0036] 100 parts of methyl ethyl ketone peroxide or cyclohexanone peroxide

[0037] Diethylene glycol 40 parts

[0038] Inorganic filler B 500-800 parts.

[0039] In the described initiator system resin anchoring agent, the inorganic filler A in the cement part is selected from one or a mixture of limestone powder and marble powder, and the inorganic filler B in the curing agent part is selected from one or a mixture of talcum powder and double fly powder .

[0040] The cement and curing agent produced according to this ratio are partially...

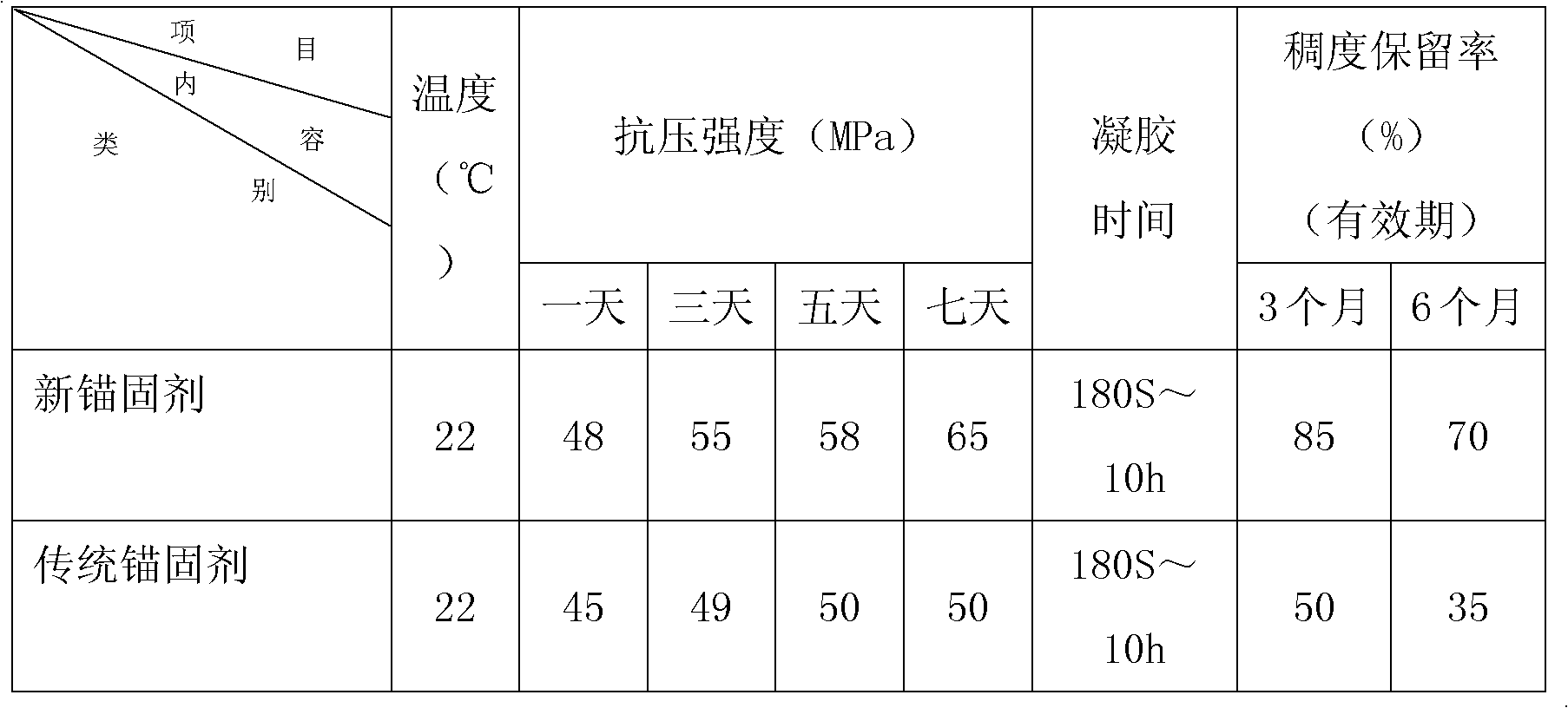

Embodiment 2

[0044] The raw material ratio of the new accelerated initiation system resin anchoring agent with a gel time of 180S~10h in terms of mass fraction is:

[0045] Clay part:

[0046] 100 parts of unsaturated polyester resin

[0047] Cobalt octanoate or cobalt naphthenate 0.2 to 4 parts

[0048] Fumed white carbon black 0~3 parts

[0049] Inorganic filler A 300~600 parts

[0050] Curing agent part:

[0051] 100 parts of methyl ethyl ketone peroxide or cyclohexanone peroxide

[0052] Diethylene glycol 40 parts

[0053] Inorganic filler B 800~1600 parts.

[0054] In the described initiator system resin anchoring agent, the inorganic filler A in the cement part is selected from one or a mixture of limestone powder and marble powder, and the inorganic filler B in the curing agent part is selected from one or a mixture of talcum powder and double fly powder .

[0055] The cement and curing agent produced according to this ratio are partially packed into the two inner cavities o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com