Grinding and polishing pad for cured grinding material based on thermal initiation curing and preparation method thereof

A technology for bonding abrasives and polishing pads, used in grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of pollution, thin polishing pad thickness, unstable performance, etc., to reduce production costs and processing efficiency. The effect of steadily improving and improving the machining surface shape accuracy and surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

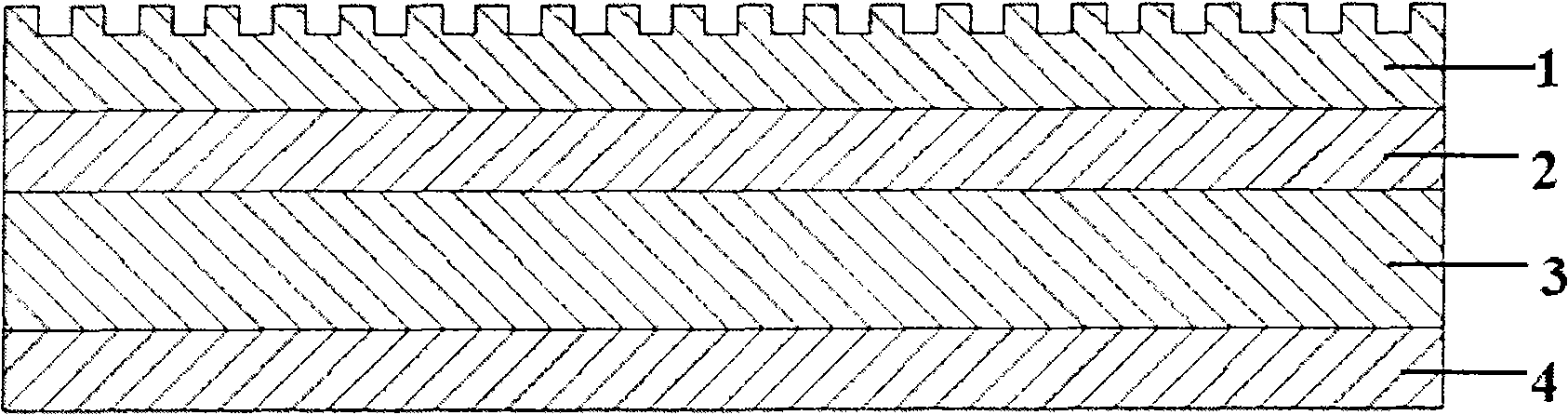

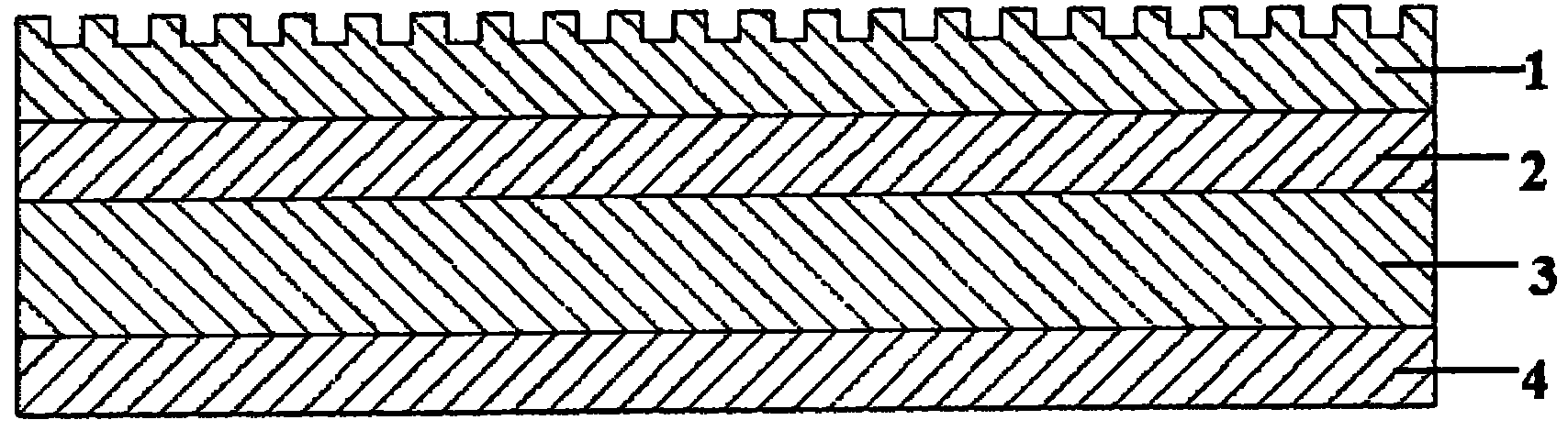

[0040] A kind of solid abrasive grinding and polishing pad based on thermally induced solidification, its structure is as figure 1 shown. The abrasive layer (1) wherein is made by the following method: take 15 grams of cerium oxide abrasives (also available silicon dioxide, aluminum oxide or silicon carbide abrasives to replace) with a particle diameter of 50 nanometers, 30 grams of polyurethane acrylate (It is also possible to use bisphenol A epoxy acrylate, epoxy acrylic acid modified by ethylamine of novolac epoxy acrylate, long fatty epoxy acrylate, polyester acrylate, polyester acrylate, etc. Polyether acrylate or acrylated polyacrylate instead), 5 grams of azobisisobutyronitrile (dibenzoyl peroxide, methyl ethyl ketone peroxide, cyclohexanone peroxide, acetyl ethyl ketone peroxide, peroxide Di-tert-butyl, dicumyl peroxide, methyl isobutyl ketone peroxide, 2,4-dichlorobenzoyl peroxide, dilauroyl peroxide, tert-butyl perbenzoate, cumene peroxide Hydrogen, 1,1-bis(tert-bu...

Embodiment 2

[0043] The nano-cerium oxide abrasive in Implementation 1 was changed to diamond abrasive, the particle size of diamond was 500 nanometers, and other compositions were the same as the preparation process. Adopt the polishing pad of above-mentioned method preparation, in NANOPOL-100 polishing machine polishing 3 inches of quartz glass plates, polishing pressure is 16KPa, and polishing disk rotating speed is 80rpm, does not contain any abrasive material in the polishing liquid, adopts ethylenediamine to regulate the pH of deionized water With a value of 9, the surface roughness of the polished quartz plate reaches 3 nm.

Embodiment 3

[0045] structured as figure 1 shown. Wherein the abrasive material layer (1) is manufactured by the following method: take 10 grams of diamond abrasives (also available silicon dioxide, aluminum oxide, cerium oxide or silicon carbide abrasives to replace) with a particle size of 14 microns, 40 grams Acrylated polyacrylate (also can use bisphenol A epoxy acrylate, epoxy acrylic acid modified by ethylamine of novolac epoxy acrylate, long aliphatic epoxy acrylate modified by oleic acid and linoleic acid , polyurethane acrylate, polyester acrylate or polyether acrylate instead), 2 grams of acetoacetone peroxide (dibenzoyl peroxide, methyl ethyl ketone peroxide, cyclohexanone peroxide, di-tert-butyl peroxide , dicumyl peroxide, methyl isobutyl ketone peroxide, 2,4-dichlorobenzoyl peroxide, dilauroyl peroxide, tert-butyl perbenzoate, cumene hydroperoxide, 1, 1-bis(tert-butylperoxy)cyclohexane, tert-butyl perbenzoate, azobisisobutyronitrile, azobisisoheptanonitrile, tert-butyl pero...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com