Penetrating type liquid hardening agent and preparation method thereof

A hardener and penetrating technology, applied in the field of hardener and its preparation, penetrating liquid hardener and its preparation, can solve the problems of small possibility of replacement, poor wear resistance, weak concrete strength, etc., and achieve strength And the effect of improving wear resistance, increasing strength and increasing degree of curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

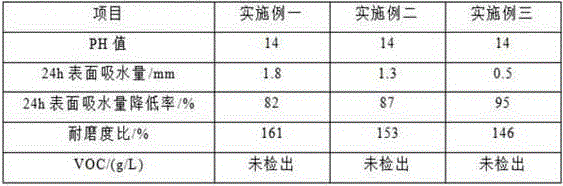

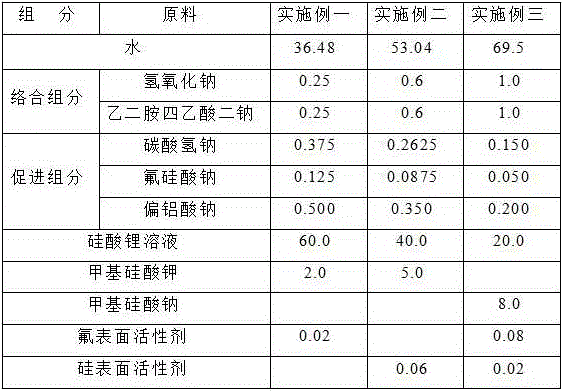

[0048] A penetrating liquid hardener, by mass (Kg), including the components in Table 1.

[0049] Table 1 Composition of penetrating liquid hardener

[0050]

[0051] Remarks: above all raw materials are all commercially available products; in embodiment one, the modulus of lithium silicate solution is 3, and mass concentration is 28%; In embodiment two, the modulus of lithium silicate solution is 8, and mass concentration is 18%; in embodiment three, the modulus of lithium silicate solution is 12, and mass concentration is 12%.

[0052] The preparation method of above-mentioned embodiment one to three is as follows:

[0053] Step 1: Weigh 70% of the water and put it in the mixer, add sodium hydroxide under low-speed stirring environment, after the sodium hydroxide is completely dissolved, slowly add disodium edetate and accelerator in turn, and carry out high-speed stirring, Until the solution is clear, and naturally cooled to room temperature;

[0054] The second step:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com