Method for detecting radial motion error of high speed principal axis by multi-ring coincidence three-point method

A high-speed spindle and radial movement technology, applied in the direction of measuring devices, measuring/indicating equipment, instruments, etc., can solve the problems of very high response time requirements, the inability to obtain spindle eccentricity errors, etc., and achieve the effect of low resolution requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

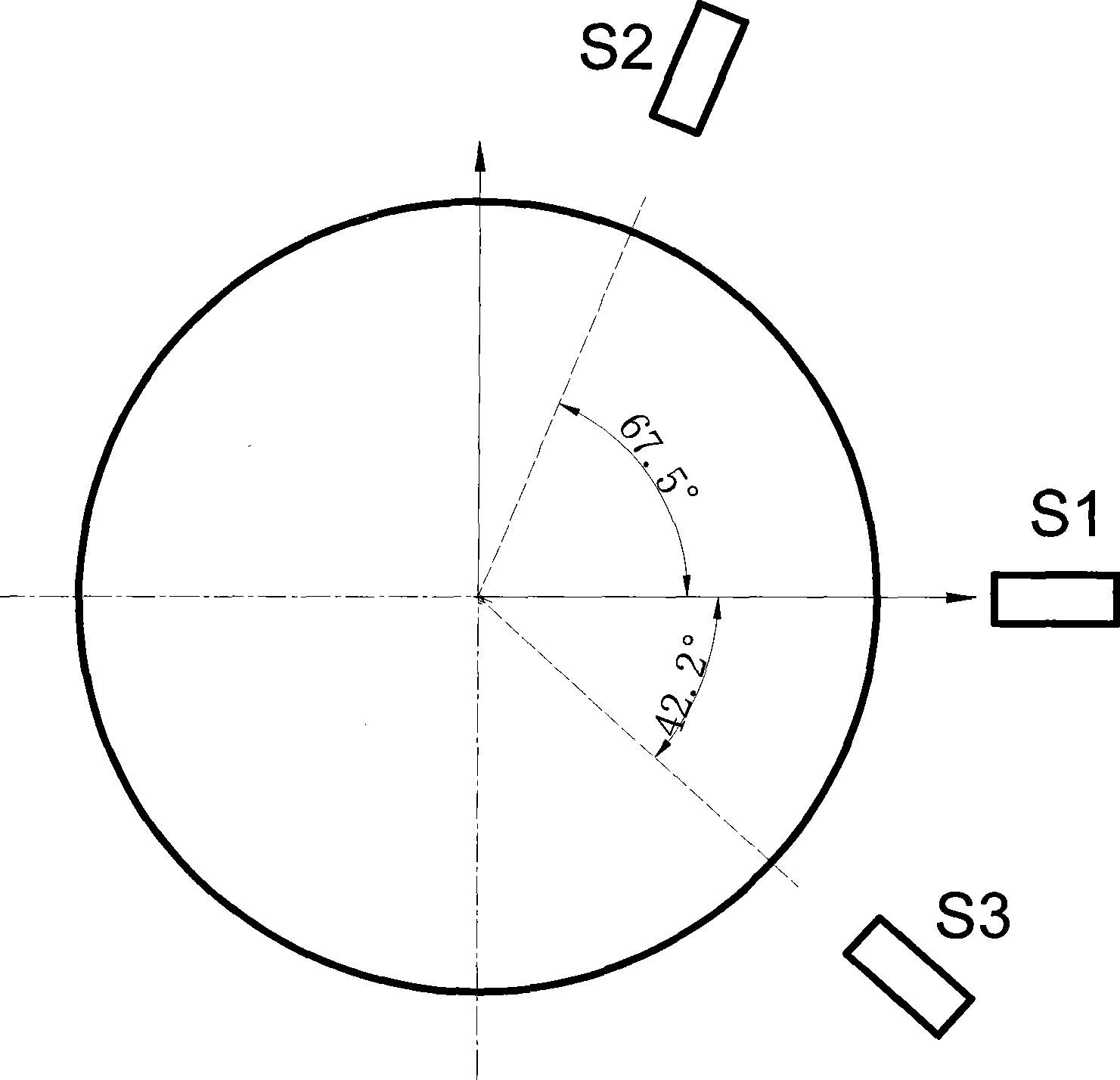

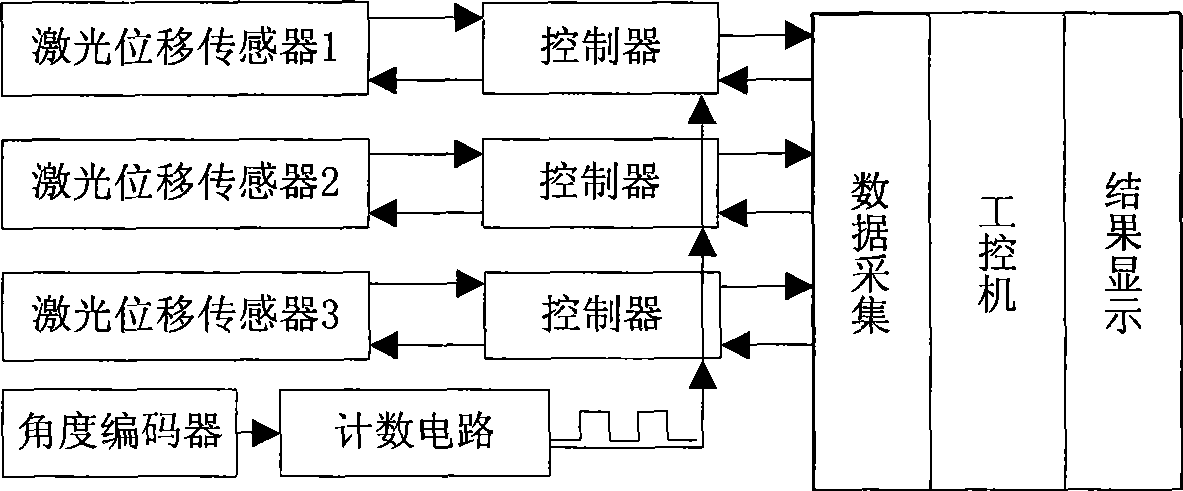

[0017] Such as figure 1 As shown, the present invention arranges three laser displacement sensors S1, S2, and S3 around the high-speed spindle, the positive angle between the first laser displacement sensor S1 and the second laser displacement sensor S2 is 67.5 degrees, and the first laser displacement sensor The negative angle between S1 and the third laser displacement sensor S3 is 42.2 degrees.

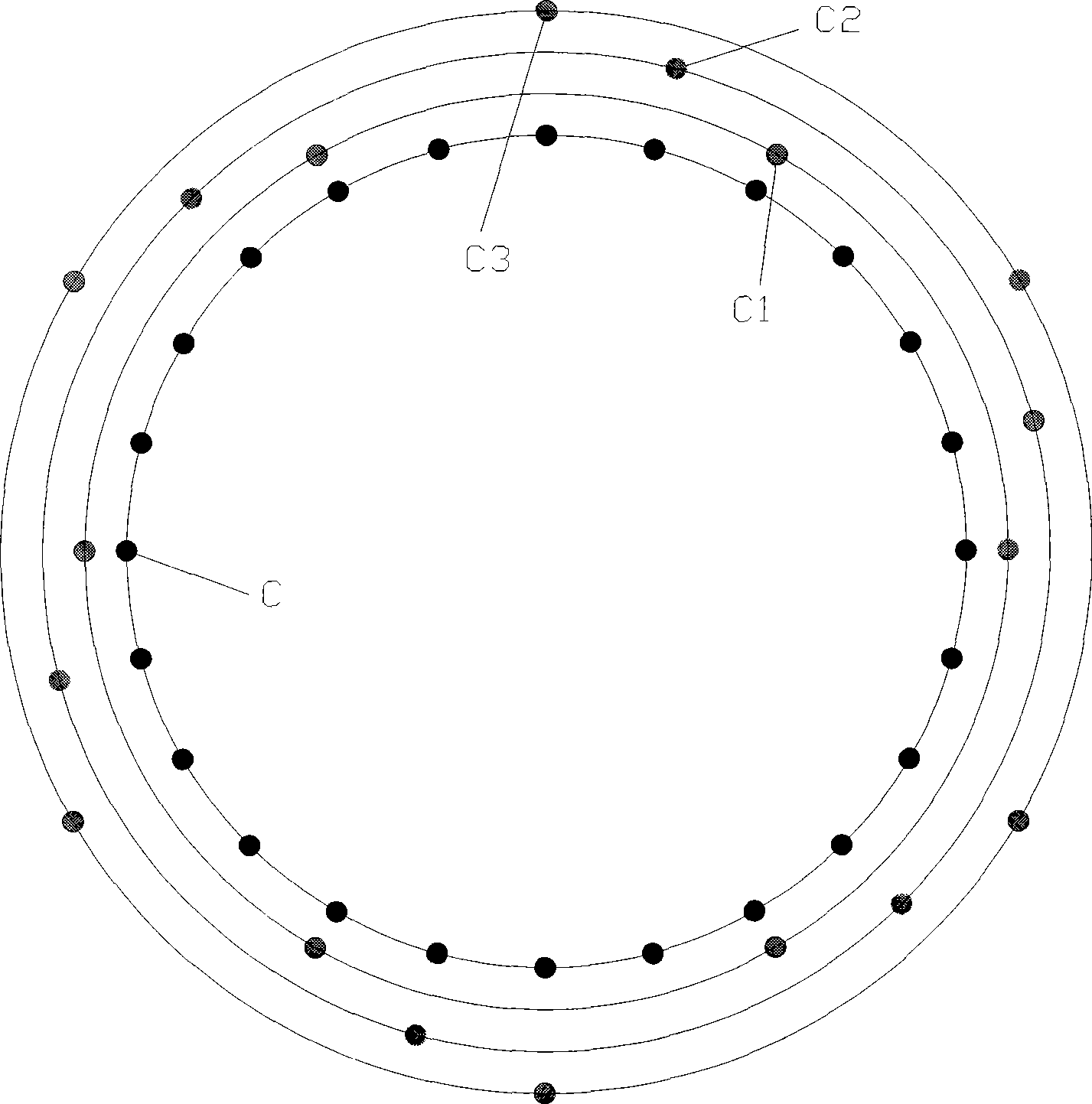

[0018] Such as figure 2 As shown, C is the point to be sampled, a total of n. C1, C2 and C3 are the sampling points when the spindle rotates the first, second and third revolutions respectively.

[0019] An angle encoder with line number N is installed on the main shaft, and the angle encoder is connected with the counting circuit. Due to the requirement of the three-point measurement method, it is necessary to sample the displacement of n (n can be divisible by N) points uniformly arranged in the circumferential direction of the main axis, and the angle between adjacent sampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com