Downhole Tool

a tool and tool body technology, applied in the field of downhole tools, can solve problems such as difficulty or inability to withdraw, and achieve the effect of minimising wear and minimising wear of bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

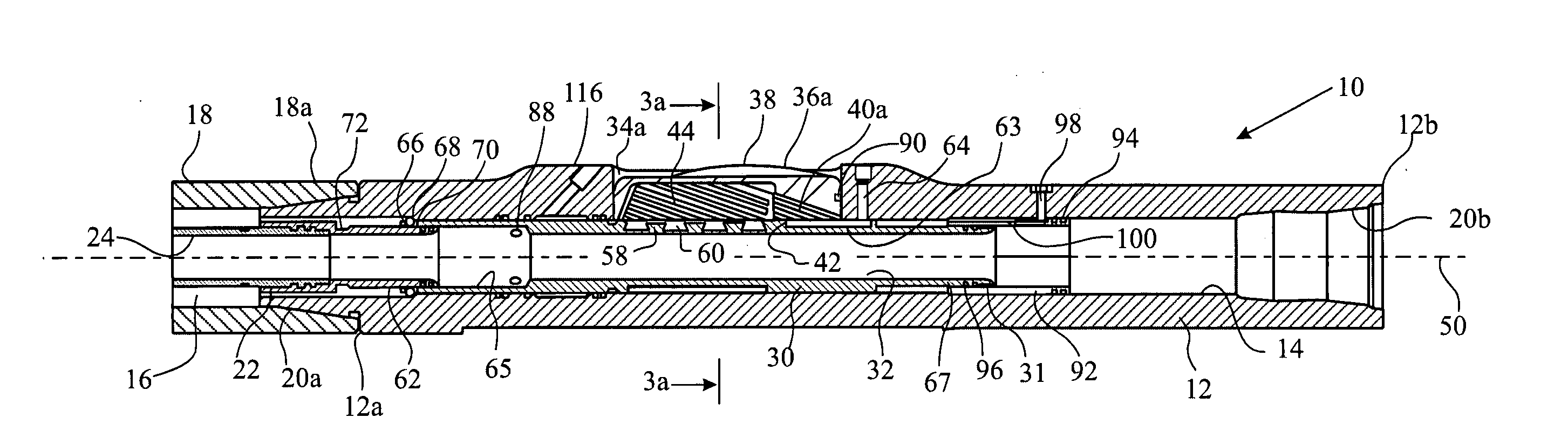

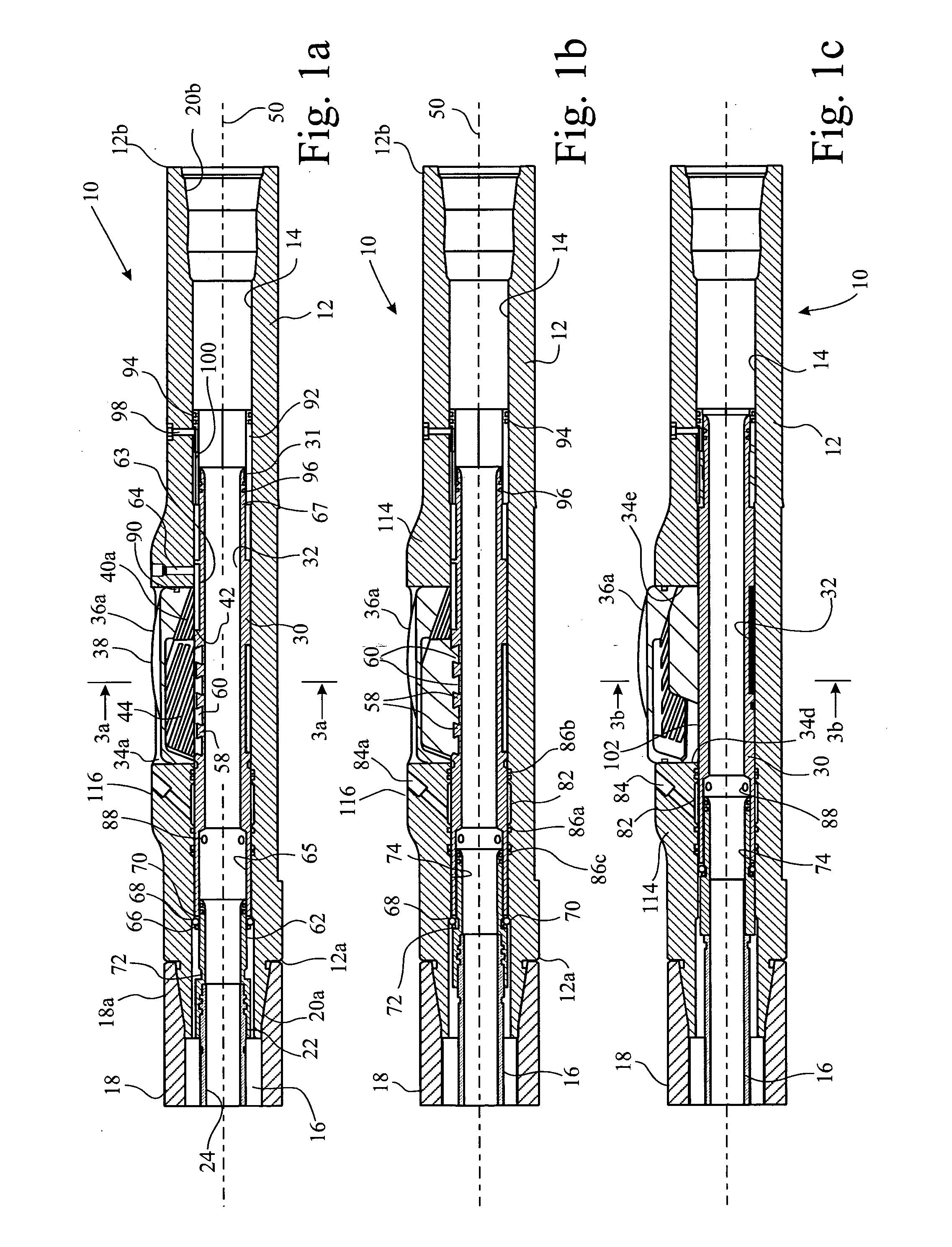

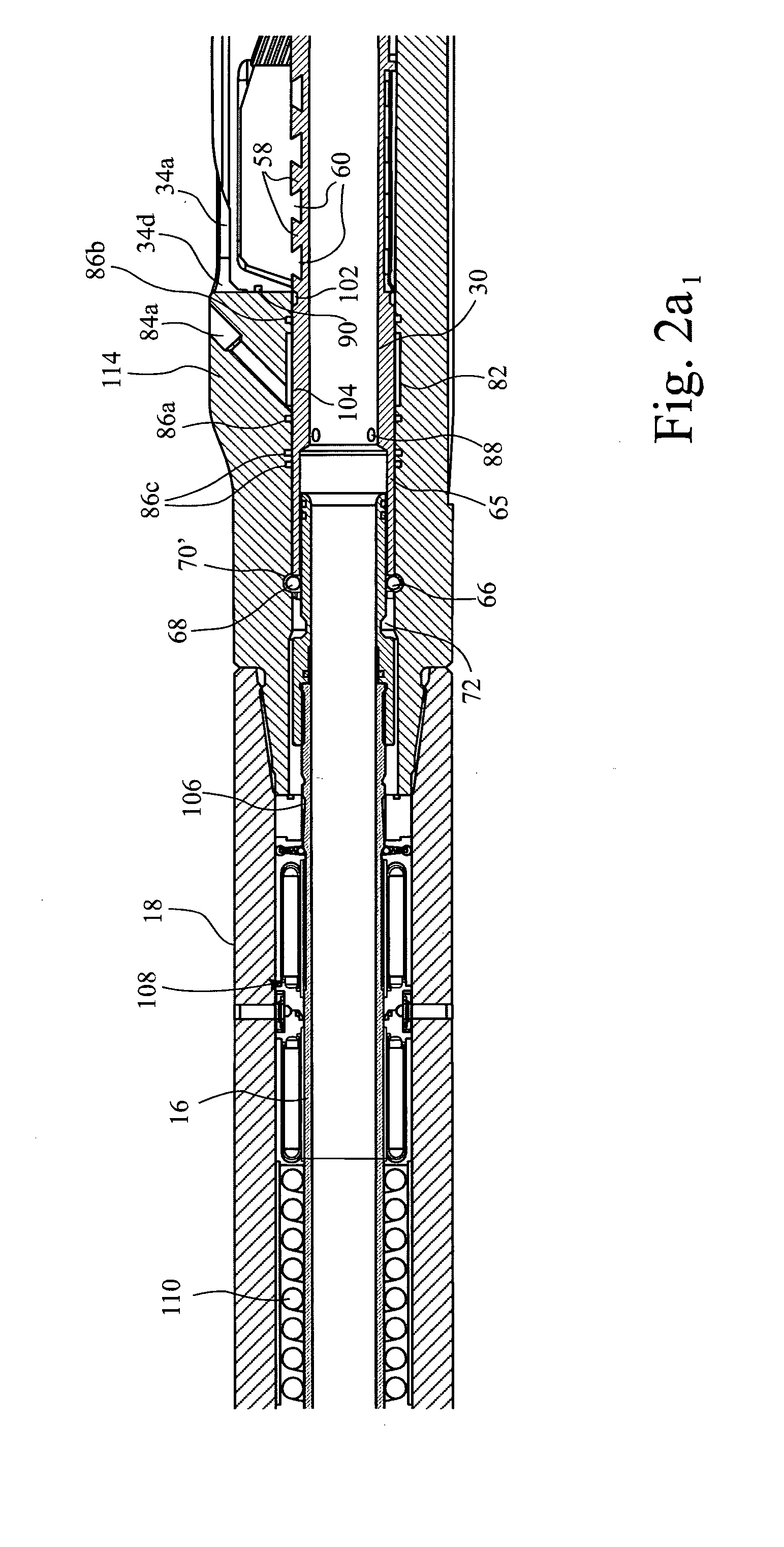

[0044]In FIGS. 1 to 3 of the drawings, an under-reamer 10 comprises a body 12 having a through-bore 14 along a longitudinal axis 50 of the tool 10. A mandrel 16 actuates the tool 10 and is a component of an actuation mechanism 18, only one end of which is shown in the drawings. The actuation mechanism 18 is connected at its end 18a to end 12a of the body 12 by a standard screw thread connection 20a. The other end 12b of the tool 10 comprises a female connection 20b.

[0045]The actuation mechanism 18 forms no part of the invention and may be in the form disclosed in WO-A-00 / 53886, U.S. Pat. No. 5,483,987, U.S. Pat. No. 6,289,999 (the entire disclosures of which are incorporated herein by reference), or any suitable means. Connected to the end of the mandrel 16 is mandrel end 22, which, conveniently, is screw threaded to the mandrel 16. However, in suitable circumstances end 22 may be integral with the mandrel 16 and henceforth is considered a part of the mandrel 16. In the drawings, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com