Support Deck for Treadmill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

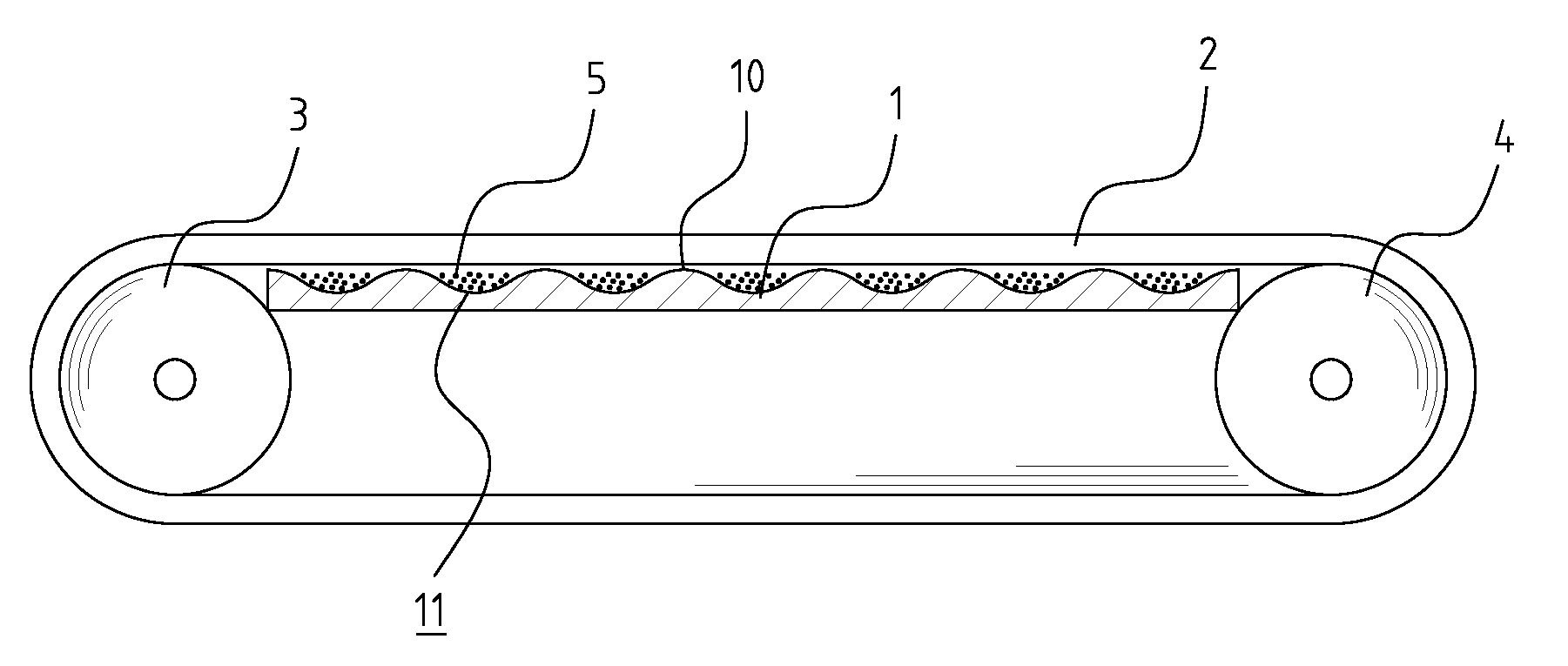

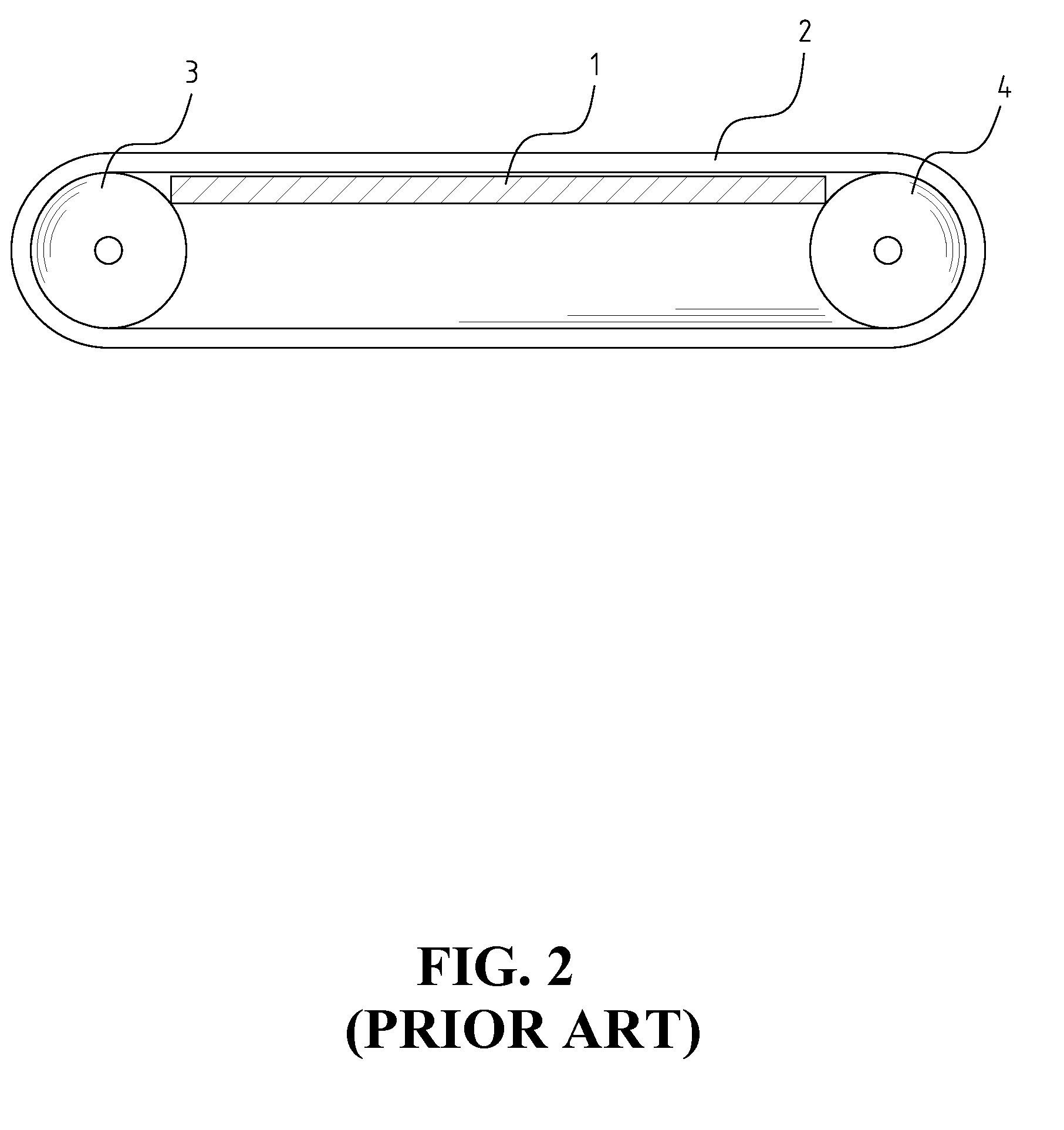

[0024]Referring to FIG. 3A, a support deck 1 for a treadmill is disposed under an upper stretch of an endless tread belt 2 to support the tread belt 2 and an user thereon. The tread belt 2 is entrained around roller 3 and 4. The support deck 1 according to the present invention includes a plurality of indentations on a top surface thereof. Lubricant or lubricating oil 5 is received in the indentations for lubrication between the support deck 1 and the tread belt 2. The support deck 1 may include curved ridges 10 (as shown in FIG. 3A) or flat surfaces (as shown in FIG. 3B) at portions between the indentations. The top surface of the support deck 1 is provided with a very smooth surface, such as a surface having mirror finish. Thus, the lubrication and the very smooth surface can further decrease the friction between the support deck 1 and the tread belt 2, thereby reducing the wear of the support deck 1 and the tread belt 2. Therefore, the life of the support deck 1 and the tread bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com