Special fixture for processing outer circle of long-cylinder part

A technology for special fixtures and parts, which is applied in the field of special fixtures for cylindrical processing of long cylindrical parts, can solve problems such as difficult control of machining accuracy, achieve high centering accuracy and improve versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

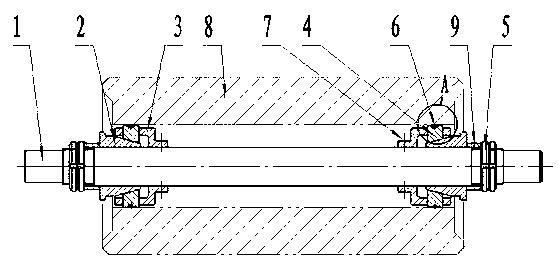

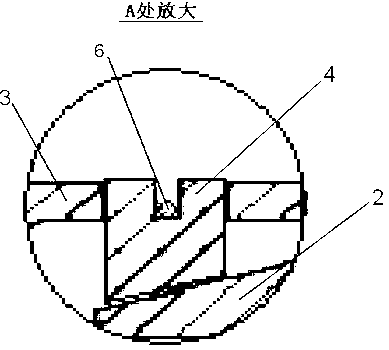

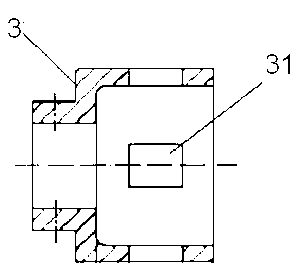

[0015] Examples: A preferred embodiment of the present invention is as follows, such as Figure 1 to Figure 4 As shown, a special fixture for external processing of long cylindrical parts is composed of the following components. The mandrel 1 is one piece, the shaft sleeve 9, the tapered sleeve 2 and the guide sleeve 3 are each two pieces, and the top block 4 is eight pieces. The ring spring 6 is two pieces, the set screw 7 is eight pieces, and the lock nut 5 is four pieces. The guide sleeve 3 has a large and small end structure, and its small end is fixed on the mandrel 1 by four set screws 7. At least one set of through holes is symmetrically provided on the large end sleeve of the guide sleeve 3. In this embodiment, two sets of four Through hole. The top block 4 is installed in the through holes. The outer end of the top block 4 is a curved surface, the inner end of the top block 4 is provided with a tapered surface, and the curved outer end is also radially provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com