Welding manipulator

A technology for welding manipulators and welding tongs, applied in welding equipment, resistance welding equipment, resistance electrode holders, etc., can solve the problems of unfavorable promotion, high initial investment and maintenance costs, etc., achieve low cost, realize high-precision feeding, and simplify the connection mechanism Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

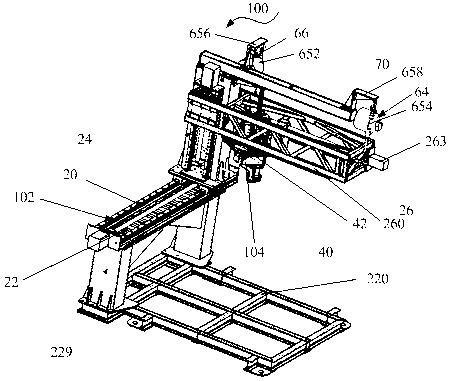

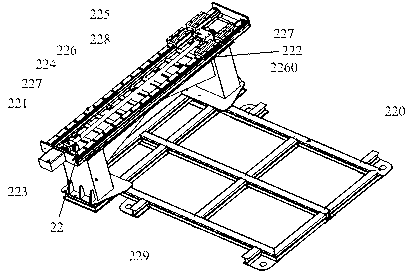

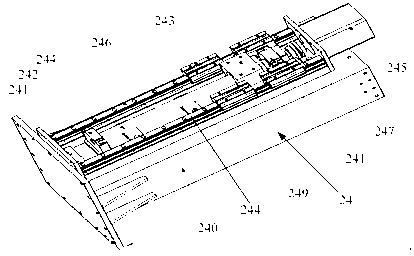

[0032] Such as Figure 1 to Figure 5 As shown, a welding manipulator 100 according to an embodiment of the present invention includes a feeding device 102 and a welding tongs 104 connected to the feeding device 102 .

[0033] Further, the feeding device 102 includes: a linear module 20 connected to the welding tongs 104 , and a rotary module 40 . The rotary module 40 includes a gear set rotary module 42 connected to the feeder 102 . The welding tongs 104 are connected and fixed on the gear set rotating module 42 .

[0034] Such as figure 1 and Figure 5 As shown, the gear set rotary module 42 includes a pair of intermeshing external gear slewing bearings 424 and a pinion 422 , and a power element connected to the pinion 422 . In this embodiment, for the convenience of arrangement and installation, the slewing support 424 is externally meshed with the pinion 422 . The power element connected to drive the pinion gear 422 includes a servo motor 421 and a reducer 423 connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com