Full-position welding method for pipeline by full-automatic external welding machine

A welding method and fully automatic technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of incompatibility of root welding speed and cover welding speed, difficulty in on-site maintenance, high automatic welding efficiency, and reduce welding speed. Seam metal filling amount to ensure effective protection and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is not limited by the following examples, and the specific implementation manner can be determined according to the above-mentioned technical solutions and actual conditions of the present invention.

[0020] Below in conjunction with preferred embodiment the present invention is further discussed:

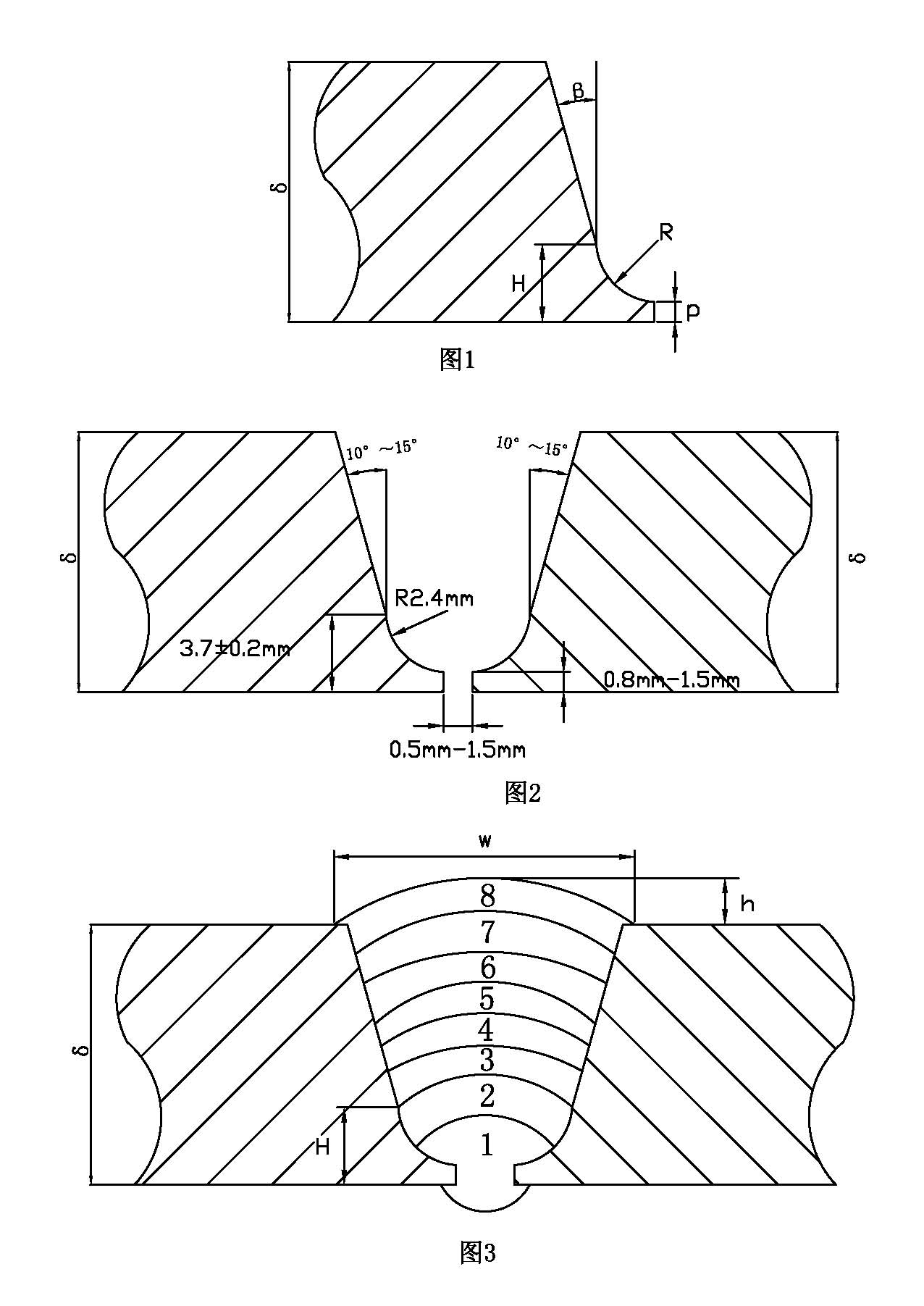

[0021] 1. Processing groove. The material of the steel pipe is X80 steel, the pipe diameter is ¢1219×18.4mm, the shape of the groove is U-shaped groove with blunt edge, and the groove machine is used for processing, such as figure 1 As shown, the upper groove angle β is 10°~15°, the height H between the inflection point of the variable groove and the inner wall is 3.7±0.2mm, the arc radius R is 2.4mm, and the blunt edge p is 0.8mm~1.5mm. All pipe end bevels must be processed by mechanical methods, and the processed bevel end faces must be flat, uniform and smooth.

[0022] During the welding process, although the torch swing frequency and le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com