Automatic welding apparatus for hard weld wires of buzzers

An automatic welding and buzzer technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of wasting labor, unsatisfactory, and low efficiency, and achieve the effects of high work efficiency, easy control, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

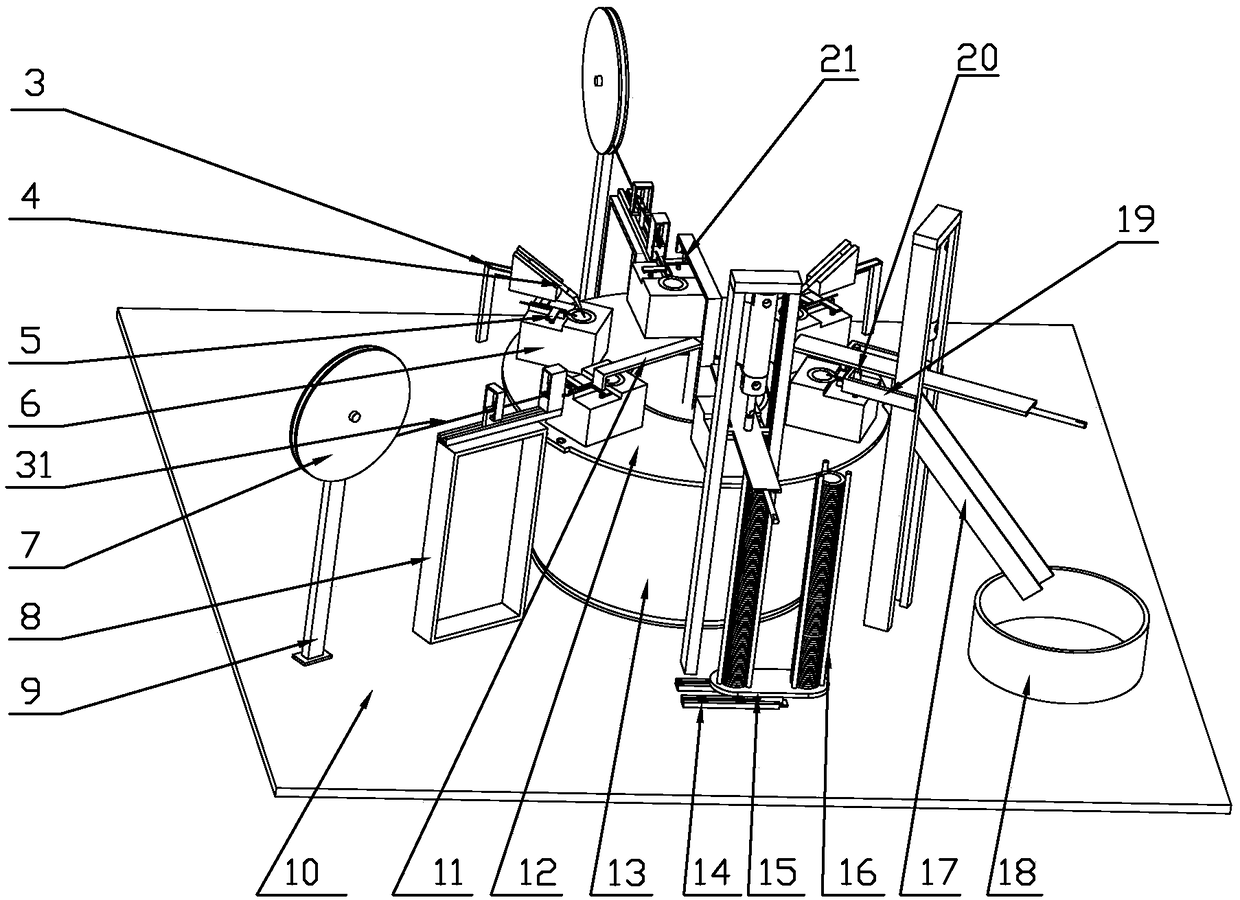

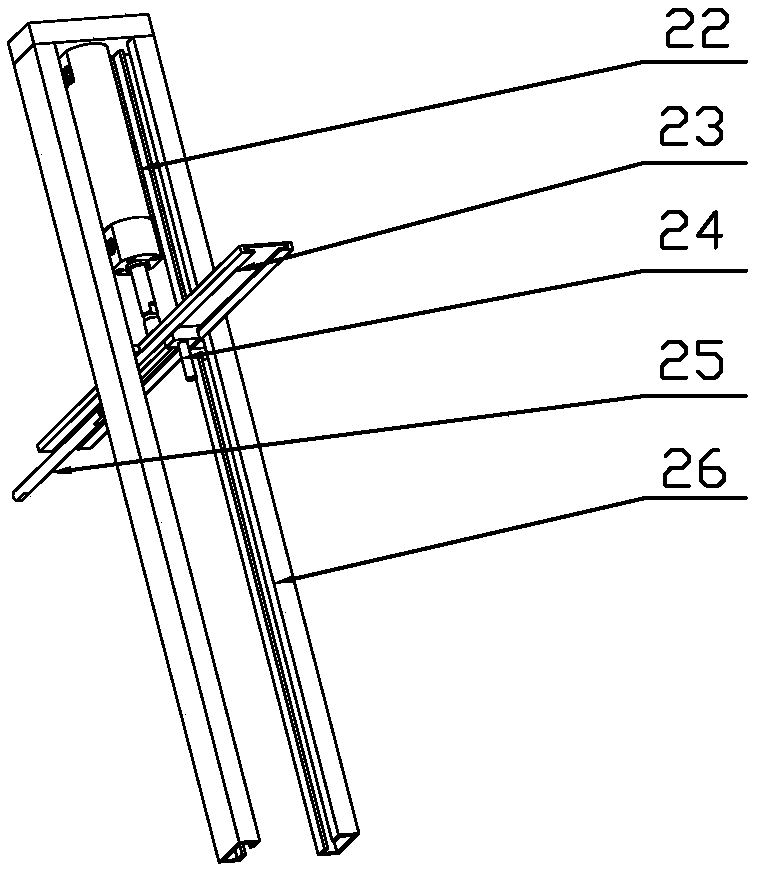

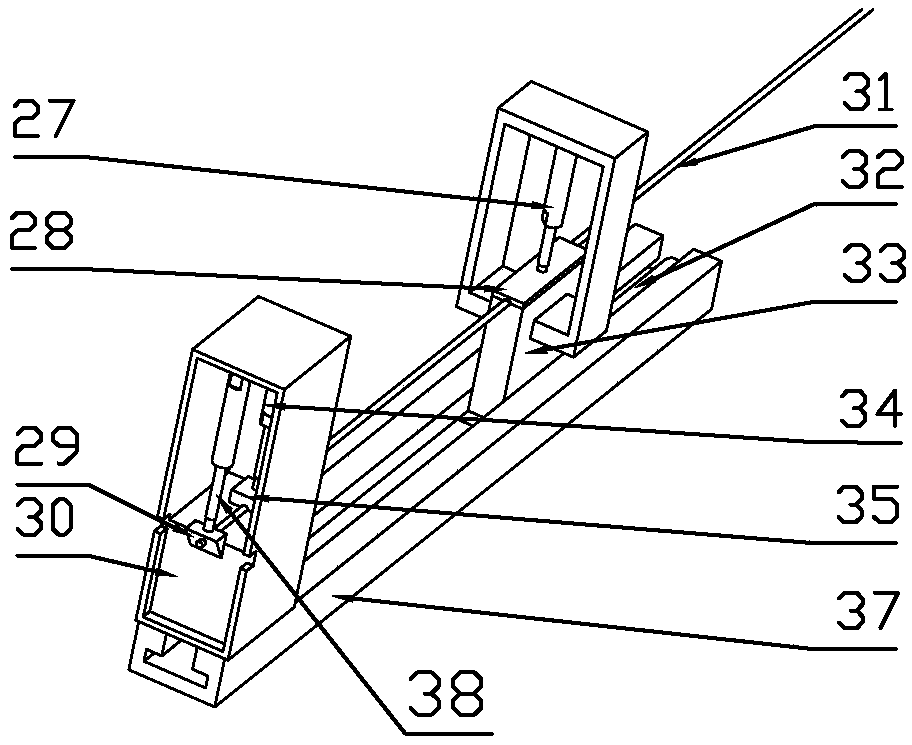

[0025] Such as figure 1 The shown automatic welding device for the hard-soldering buzzer chip includes a base plate 10, a round table 13, a rotating plate 12, a stepping motor (not shown in the figure), a number of (six in the figure) clamps 6, a feeding station, the first A wire feeding station, a first welding station, a second wire feeding station, a second welding station and a discharging station.

[0026] The round platform is fixed on the base plate; the rotating plate is annular, and the rotating plate is horizontally arranged and rotatably positioned on the round platform around a vertical axis (the rotating plate is rotatably positioned on the round platform through a ring track). Under the control of the PLC controller, the stepping motor drives the rotating plate to perform intermittent motion (the bottom surface of the rotating plate is fixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com