Welding robot for lidless box

A welding robot and box technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of insufficient welding quality, and achieve the effect of improving welding efficiency and welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

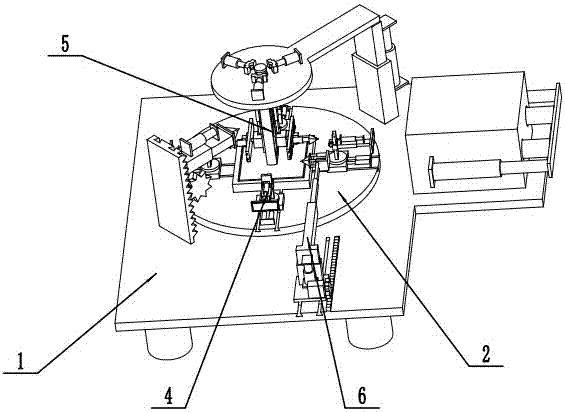

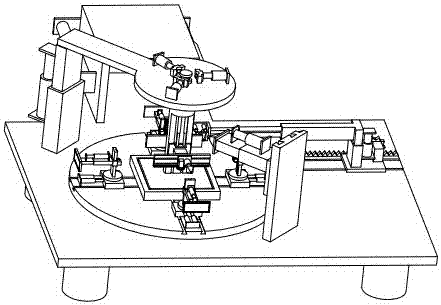

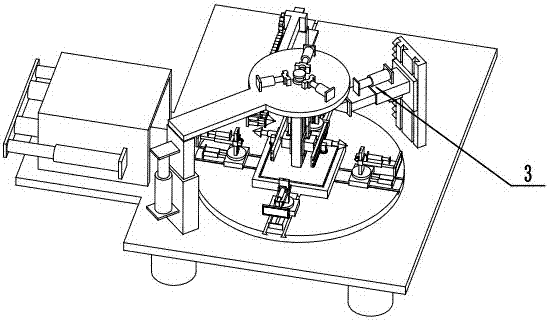

[0021] Example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 As shown, a welding robot without a cover, including a base 1, a bottom steel plate fixing part 2, an external welding part 3, four steel plate pick-and-place parts 4, an internal welding part 5, and a side welding part 6, is characterized in that: The middle part below the bottom plate 201 of the bottom steel plate fixing part 2 is fixedly connected with the motor shaft of the first stepping motor 106, and the first ring groove 210 is slidably installed on twenty first balls. 105, the second ring groove 211 is slidably installed on the ten first balls 105; the two second sliders 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com