Turnover mechanism for automatic welding of welding seams of cylinder

A turning mechanism and automatic welding technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high production cost, low welding efficiency, and unsightly appearance, so as to improve welding efficiency and welding The effect of quality, weld uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

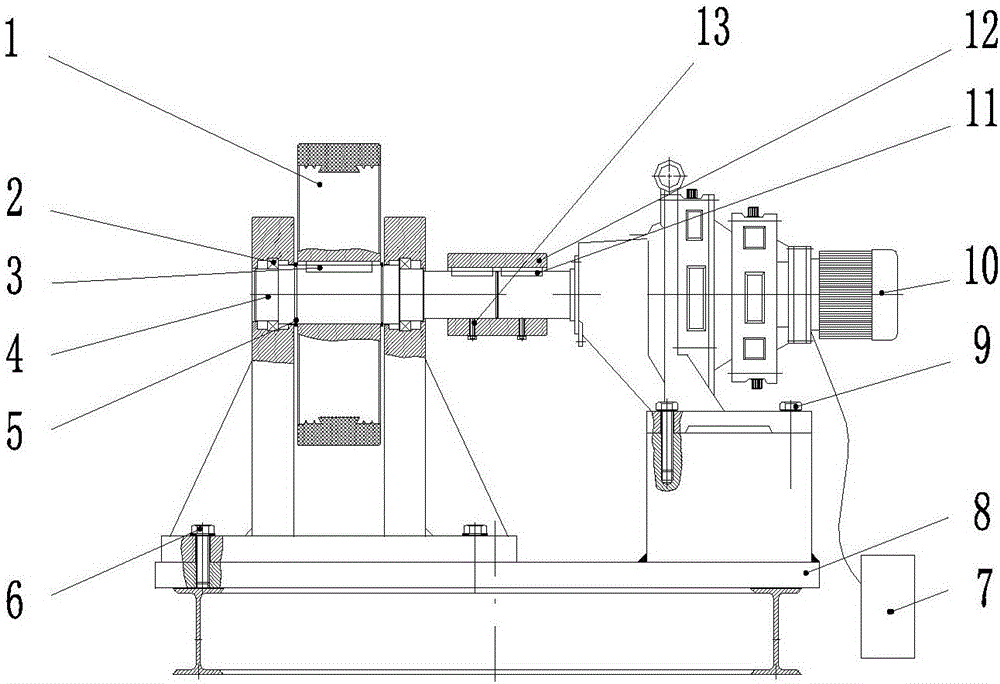

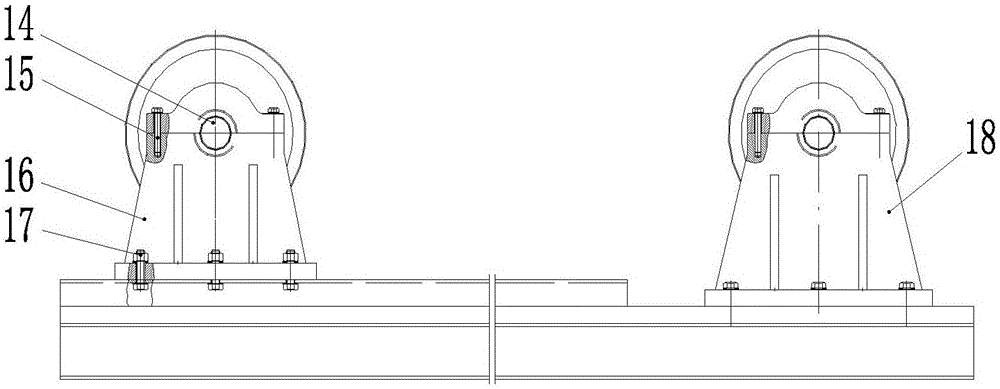

[0019] Now in conjunction with accompanying drawing, the present invention will be further described, as figure 1 , figure 2 As shown, it includes a roller 1 , a frequency converter 7 , a base 8 and a motor 10 . like figure 1 As shown, the surface of the roller 1 (the contact surface with the welded cylinder) is inlaid with rubber to prevent the cylinder from slipping due to small friction when turning over. This overturning mechanism has two groups of rollers altogether, and each group all comprises fixed roller 18 and adjustable roller 16 each one, and fixed roller 18 is fixed on the base 8 with fastening bolt 6, and the position can not move ( figure 2 ); the adjustable roller 16 is fixed on the bottom platform with the adjustable roller positioning pin 17; the bottom platform 8 is provided with a plurality of fixing holes; according to the diameter of the welded cylinder, the adjustable roller positioning pin 17 is connected with different fixing holes , can adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com