Robot automatic welding method for special-shaped box

An automatic welding and special-shaped box technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of complex crane quay bridge box girder components, low automation of welding equipment, and unstable welding production quality, etc., to achieve Save consumables and labor costs, improve automation productivity, and ensure the uniformity of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

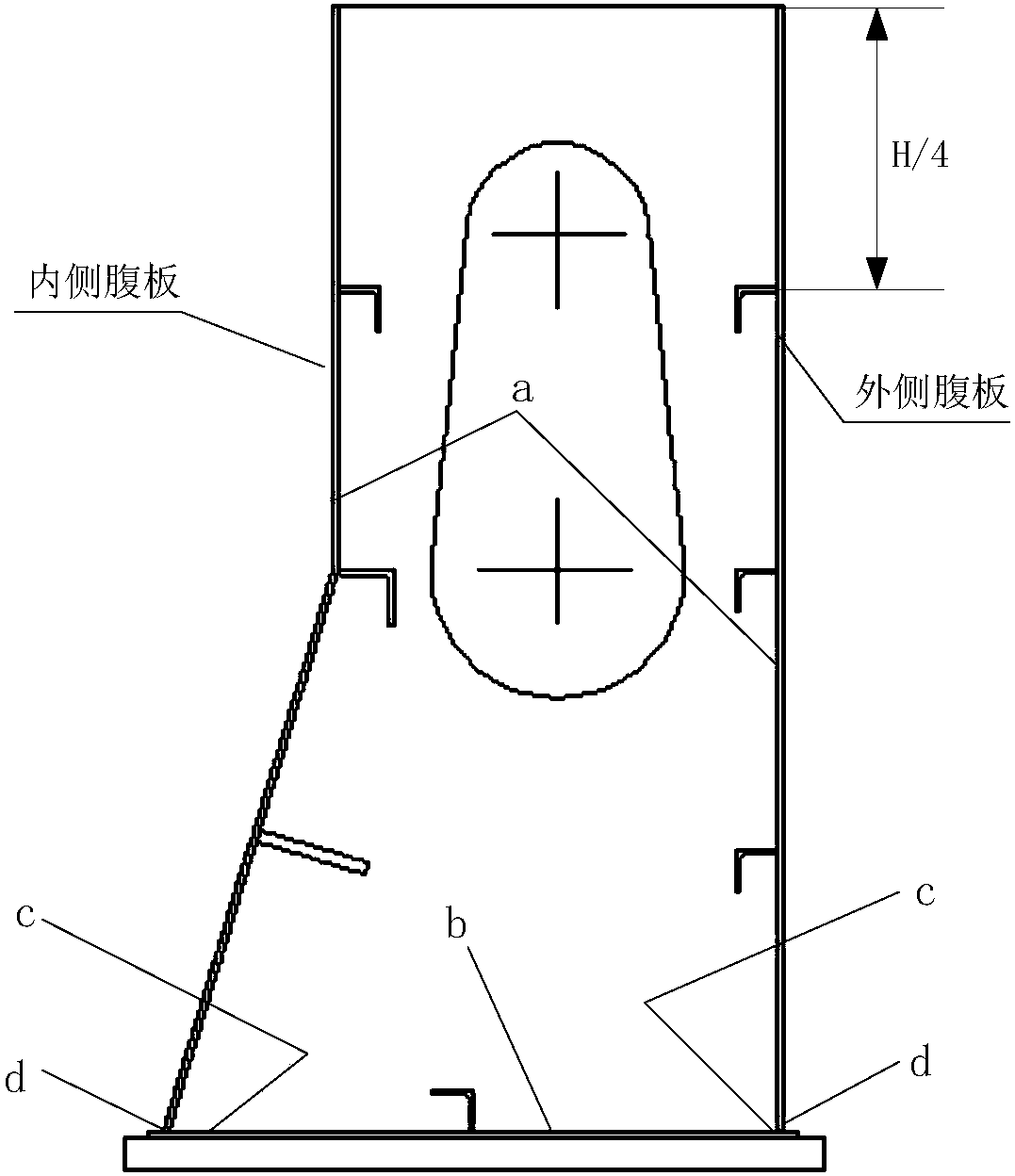

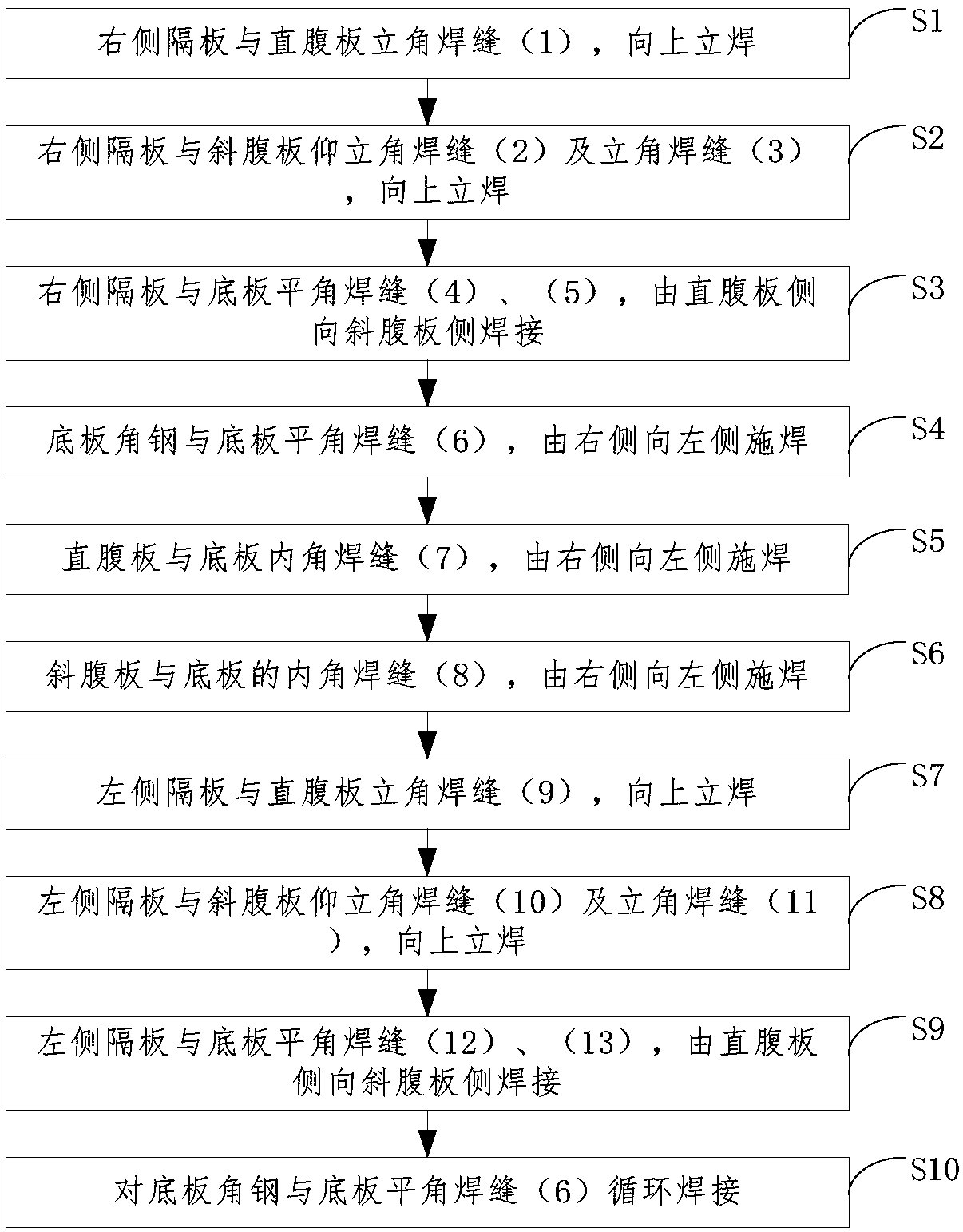

[0031] Traditional girder manual welding process. combine figure 1 , first carry out three-sided molding assembly, and the welding sequence after three-sided molding is: a. The vertical weld between the partition and the web. Note that there should be a H / 4 at the top that is not welded temporarily; b. The partition and the lower wing c. The connection weld between the inner side of the box web and the lower wing (note that there is no welding for two meters at the hinge point); d. The connection weld between the outer side of the box web and the lower wing.

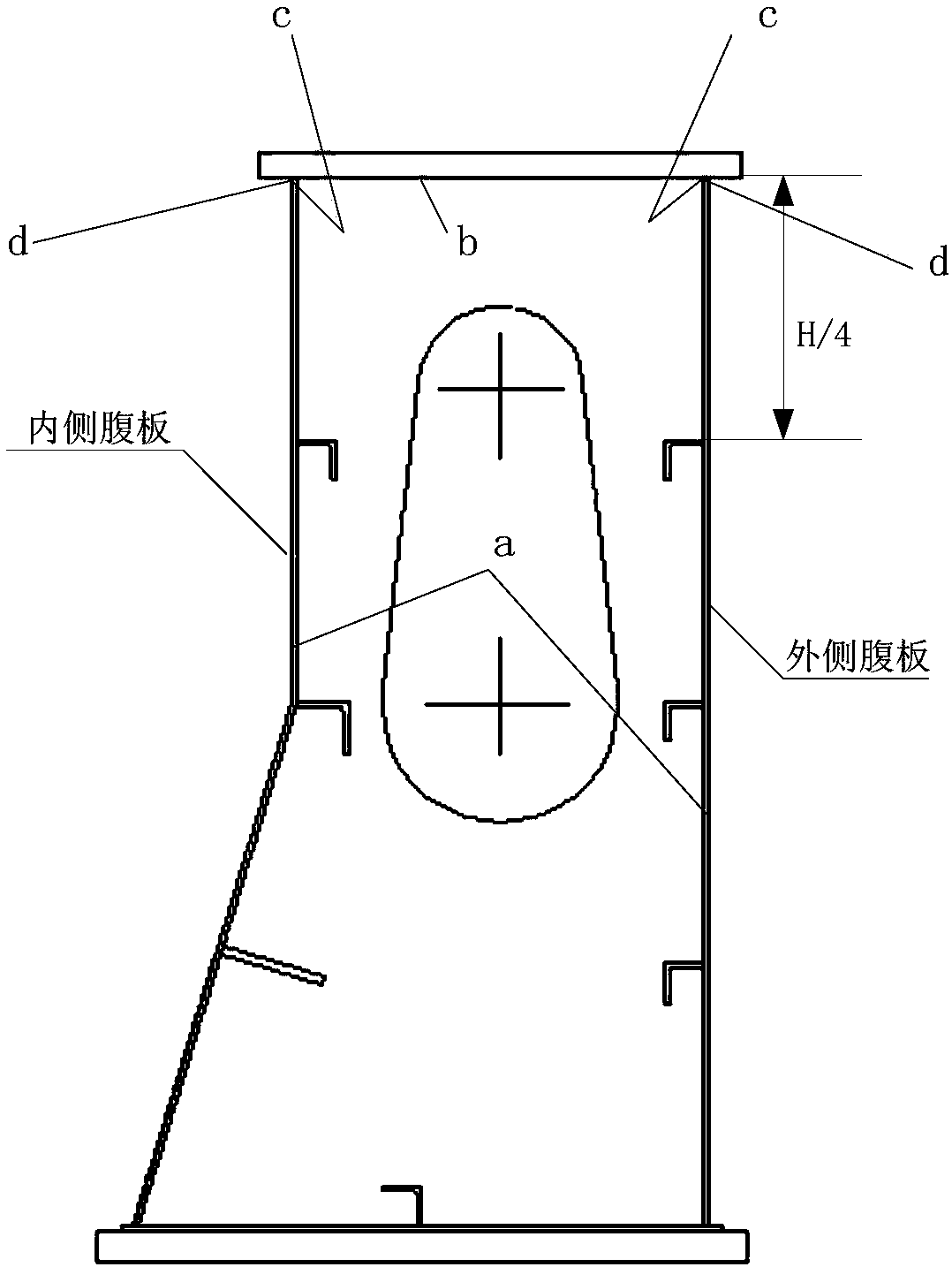

[0032] combine figure 2 , and then four-sided forming cover plate, welding sequence: a, H / 4 vertical weld between the partition and the web; b, connection weld between the partition and the upper wing; c, the inner web of the box and the The contact weld of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com