A three-degree-of-freedom satellite high-precision component assembly and adjustment mechanism

A degree of freedom and high-precision technology, applied in electrical components, antennas and other directions, can solve the problems of large floor space, complex installation and adjustment mechanism, collision interference, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

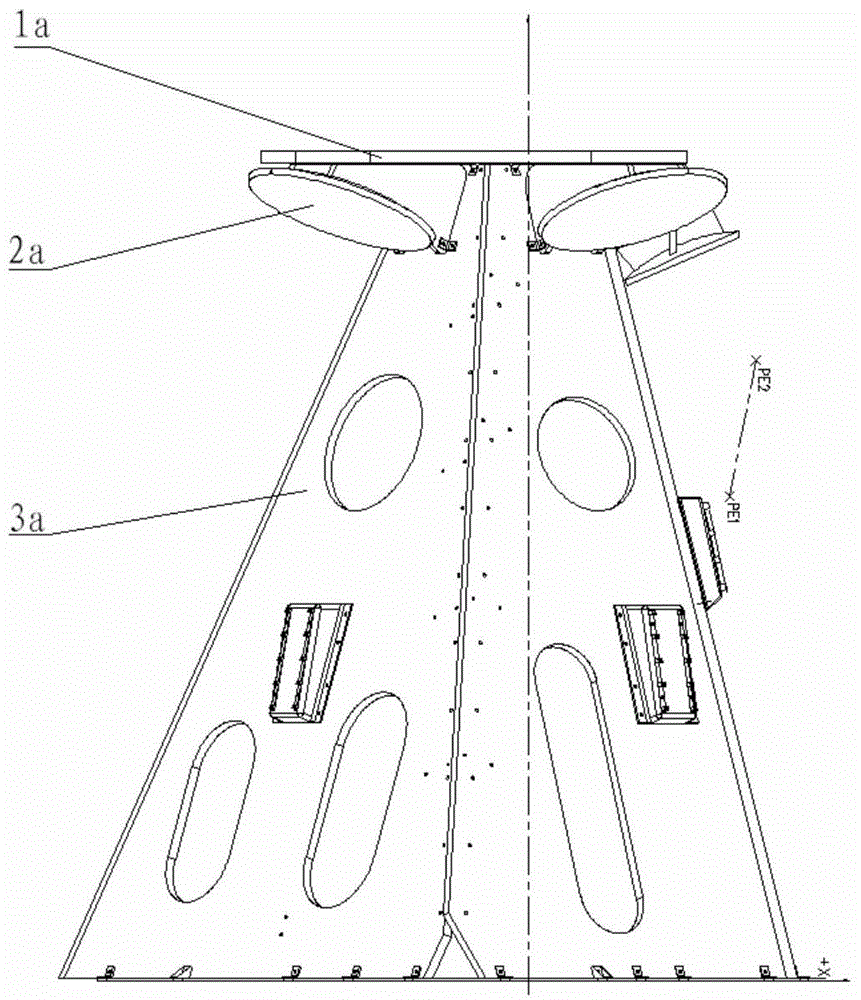

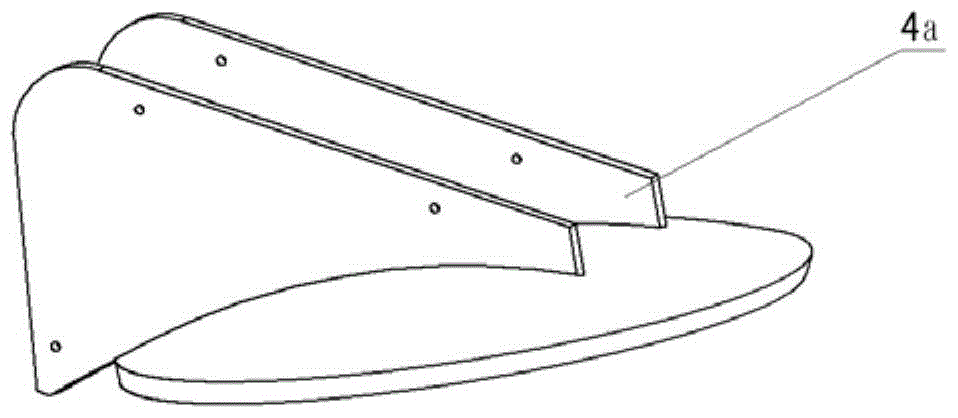

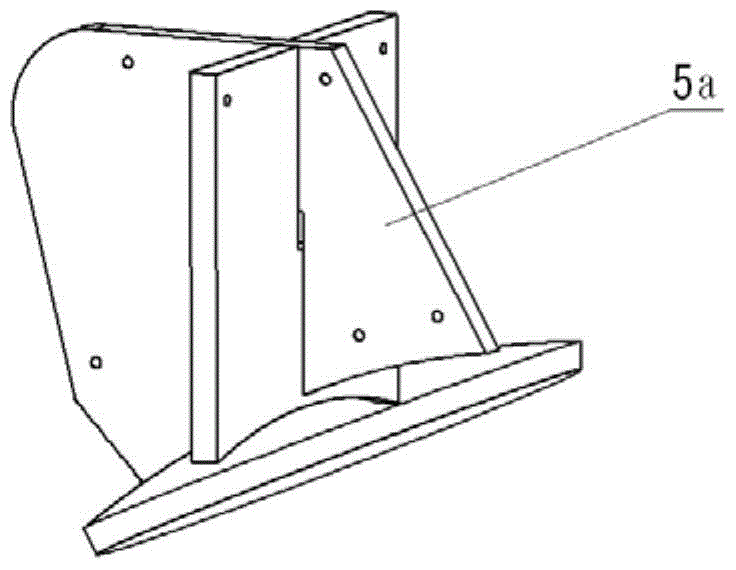

[0020] Such as Figure 6 As shown, a three-degree-of-freedom satellite high-precision component assembly and adjustment mechanism of the present invention adopts a split-type design, including a three-degree-of-freedom displacement adjustment device 1, a clamping mechanism 2 and a base 3; The reflectors installed at different positions on the surface are taken as an example to illustrate.

[0021] The three-degree-of-freedom displacement adjustment device 1 realizes the displacement adjustment of the X, Y, and Z axes. When used together with the base 3, it realizes the position transformation so as to adjust the reflectors in multiple different positions, and ensures that the displacement direction is consistent with the respective assembly coordinate system. Parallel, that is, the three-degree-of-freedom displacement adjustment device 1 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com