Locomotive capacitor shell seam welding machine

A technology of capacitors and welding machines, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as defective products, uneven solder joints, and product quality impacts, and achieve good quality of weldments, improve labor efficiency, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

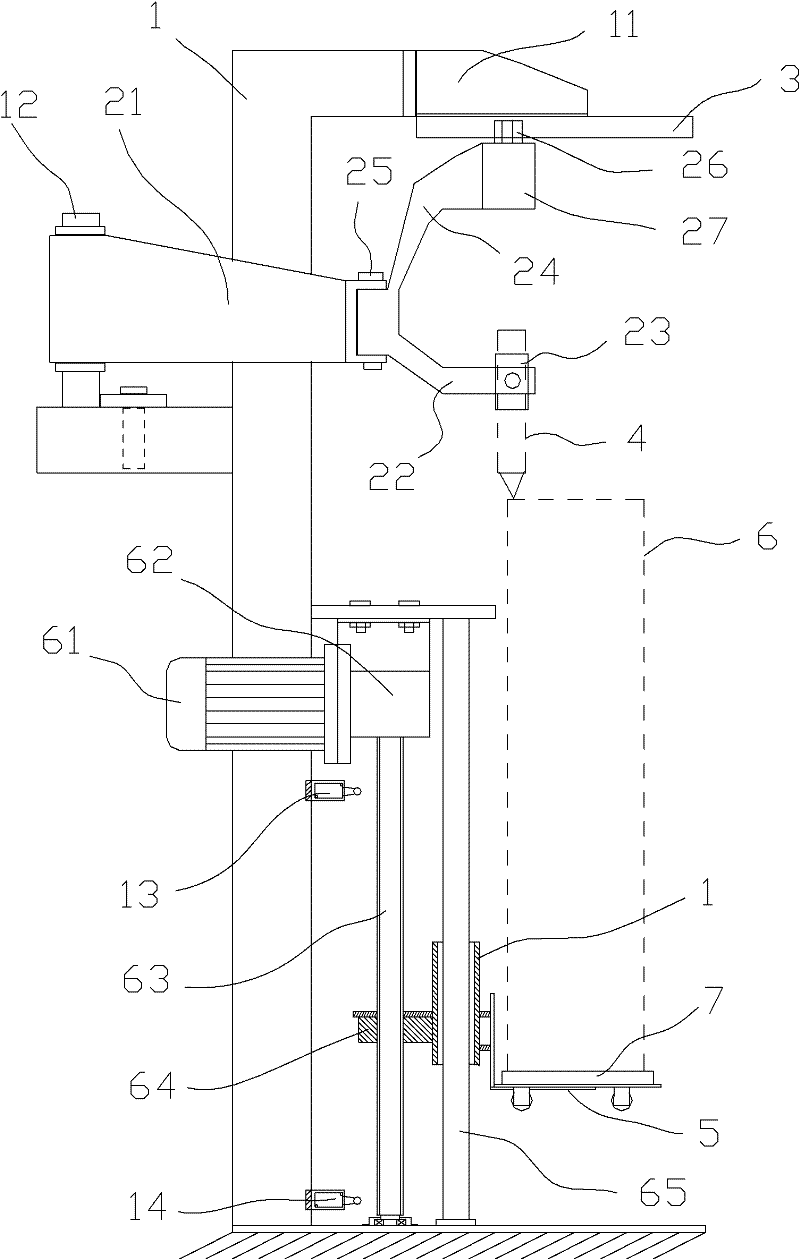

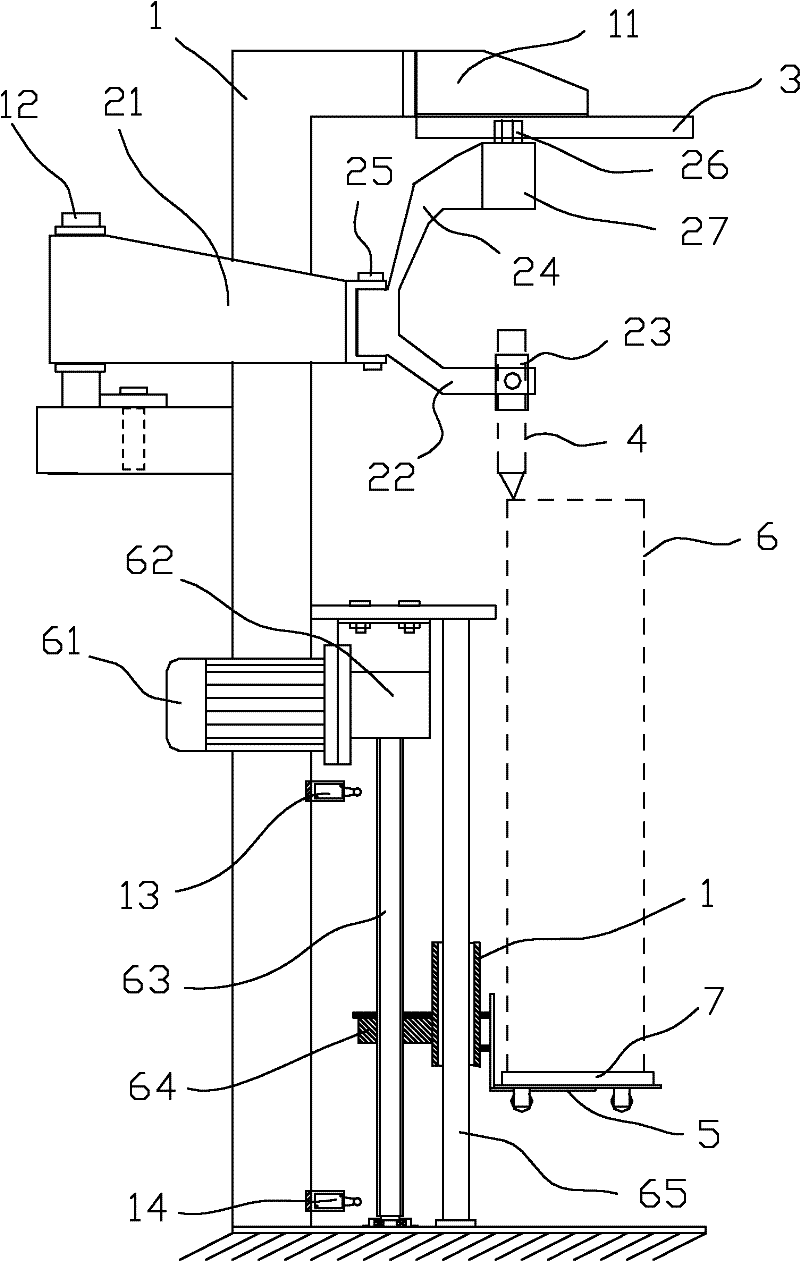

[0013] Depend on figure 1 with figure 2 As shown, a workbench 5 and its lifting device are arranged below the frame 1, and the lifting device is composed of a motor 61, a worm gear reducer 62, a screw 63, a guide rod 65, and a slider 64, and the screw rod 63 and the guide rod 65 are vertically arranged , the slider 64 is fixed on one side of the workbench 5, and the slider 64 has an internal thread that matches the screw mandrel 63 and a vertical guide hole that matches the guide rod 65. When the motor 61 is driven, the screw mandrel 63 is driven by the worm gear reducer 62 Rotate so that the slide block 64 on the screw mandrel 63 moves vertically along the guide rod 65. Proximity switches 13, 14 for controlling the upper and lower limit positions of the slider 64 are provided on the frame 1 .

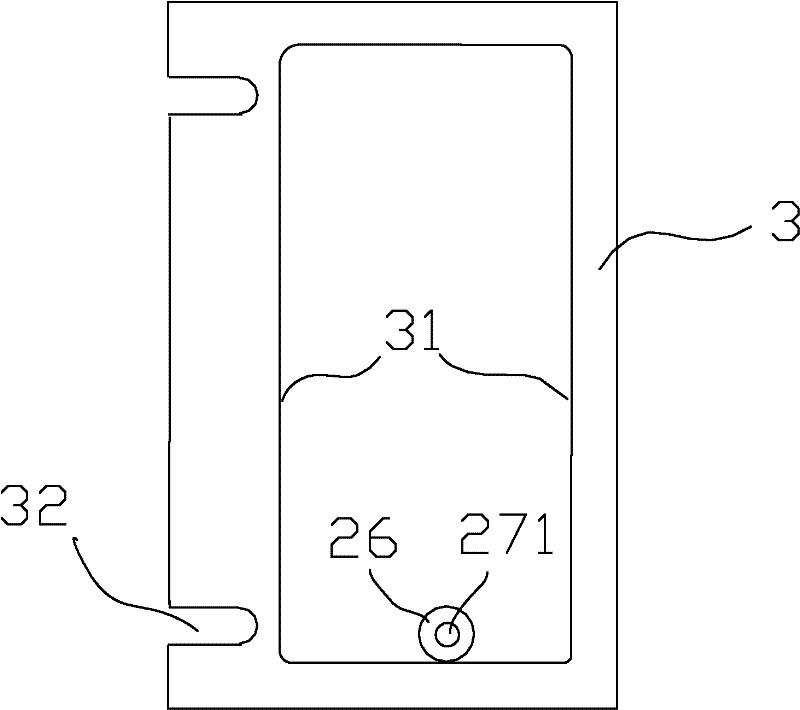

[0014] The mechanical arm is arranged above the workbench 5 and consists of two sections of front and rear swing arms 21, 22 hinged by pin shafts 25. The other end of the rear swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com