Production process of range hood

A production process and a technology for range hoods, which are applied in the direction of manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve problems such as poor welding effect, and achieve the effect of fewer defects, reducing the possibility of unwelded, and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

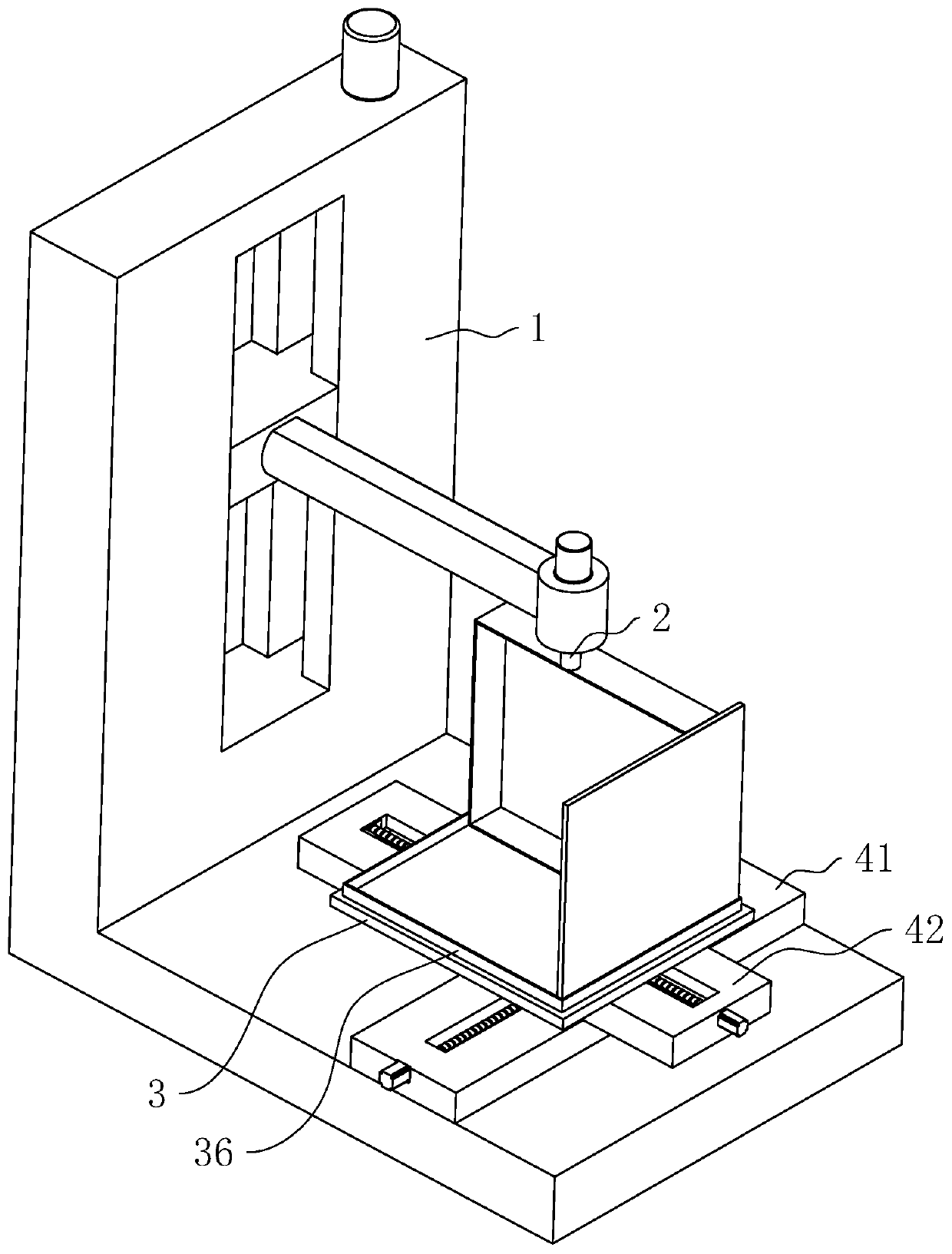

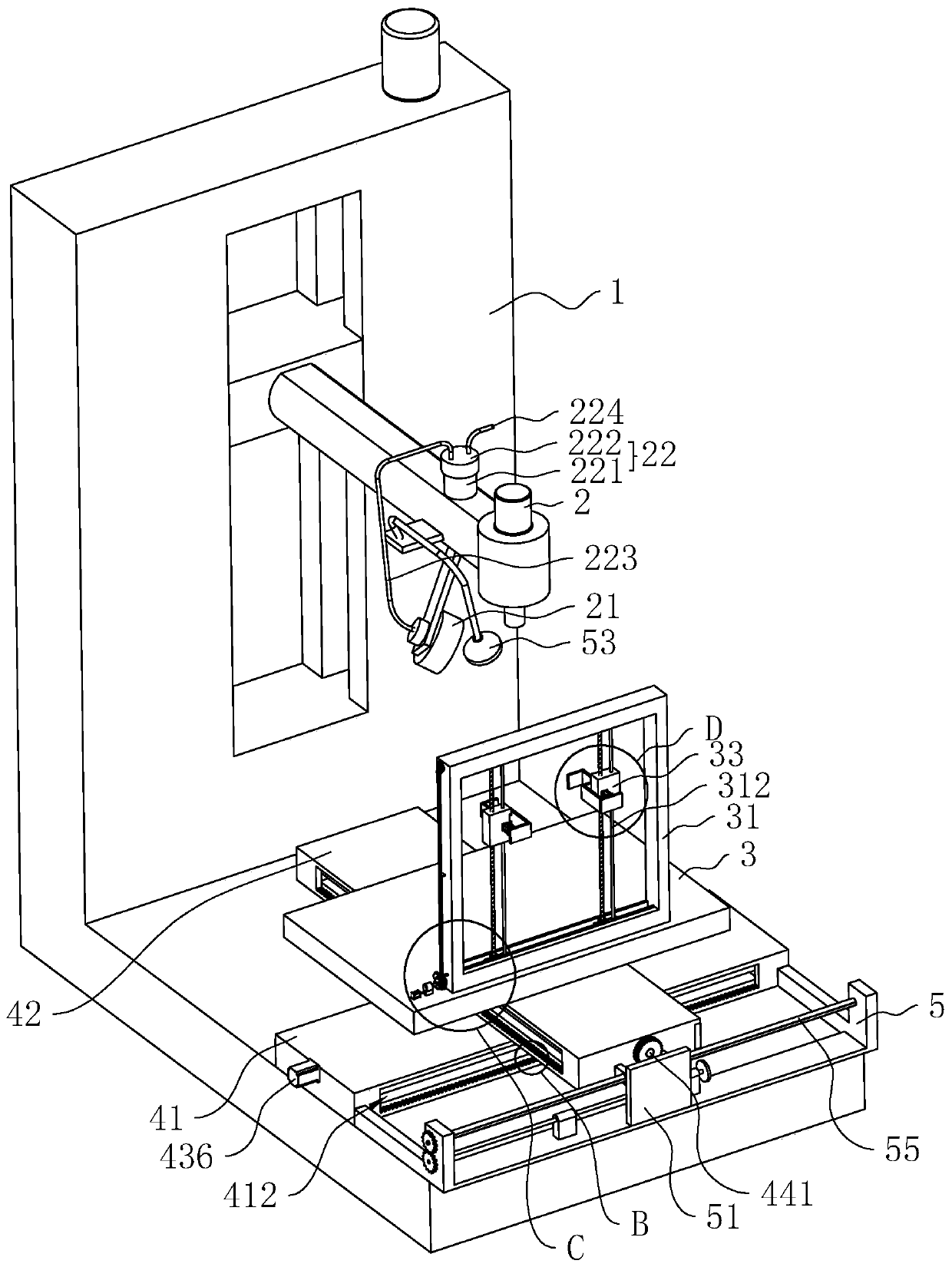

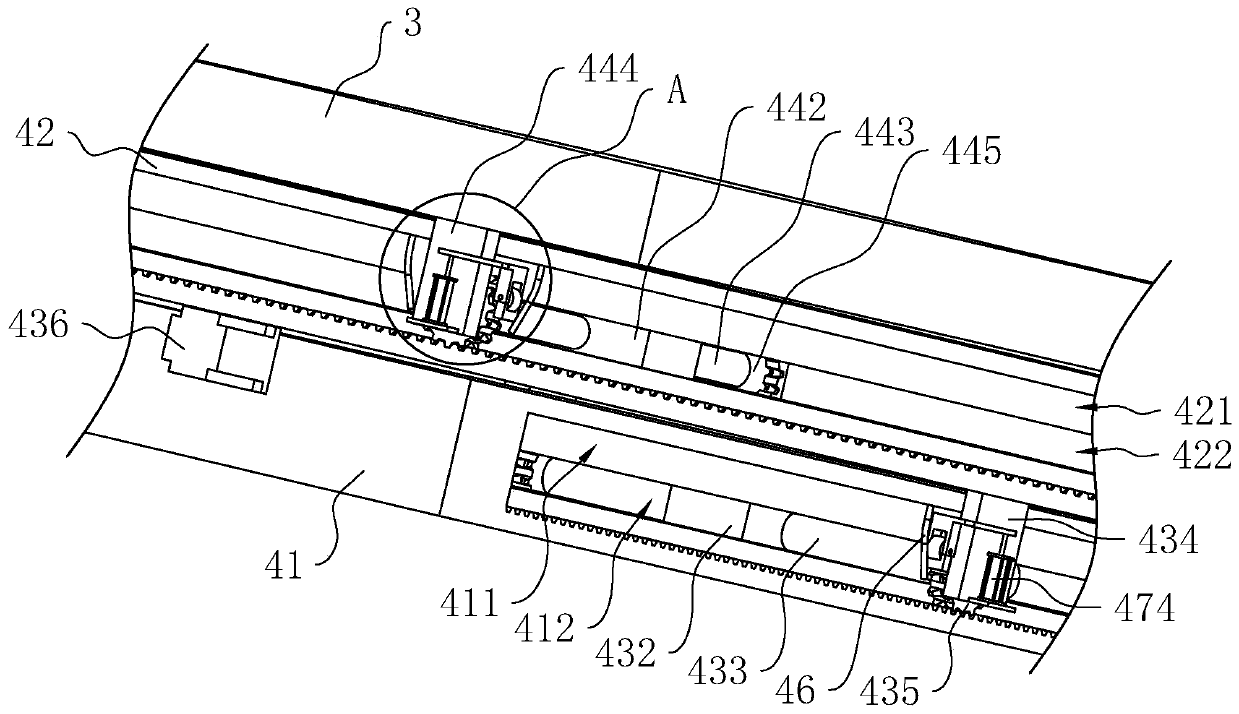

Image

Examples

Embodiment 1

[0113] The difference between Examples 18-22 and Example 1 is that each component in the active agent is calculated in the following table by weight percentage.

[0114] Example sodium fluoride calcium fluoride silica acetone Example 18 13.75 8 5.75 72.5 Example 19 12.5 7 6.5 75 Example 20 11.25 6 7.25 77.5 Example 21 10 5 8 80 Example 22 11 9 5 75

[0115] The difference between Examples 18-26 and Example 1 is that each component in the surface treatment agent is calculated in the following table by weight percentage.

[0116] Example Pure crystalline silicon powder Silicic acid extender extender Example 23 22.5 15 0.45 62.05 Example 24 25 20 0.5 54.5 Example 25 27.5 25 0.55 46.95 Example 26 30 30 0.6 39.4

[0117] The difference between Examples 27-31 and Example 1 is that each component in the spreading agent is calculated as the following table by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com