Wellhead butt joint device and butt joint method thereof

A docking device and calibration device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems affecting welding quality, welding skew, easy to shake, etc., to improve welding quality and welding efficiency, simple operation, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

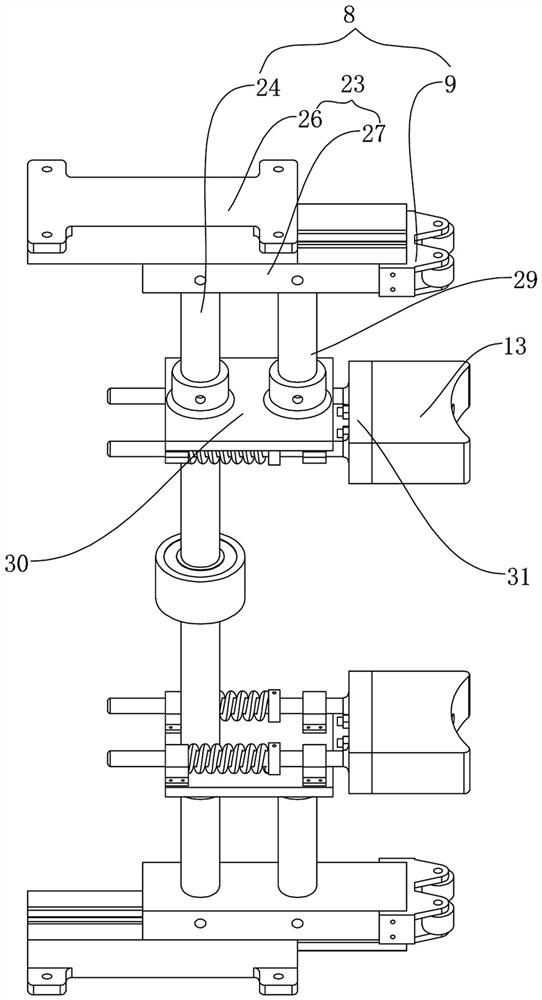

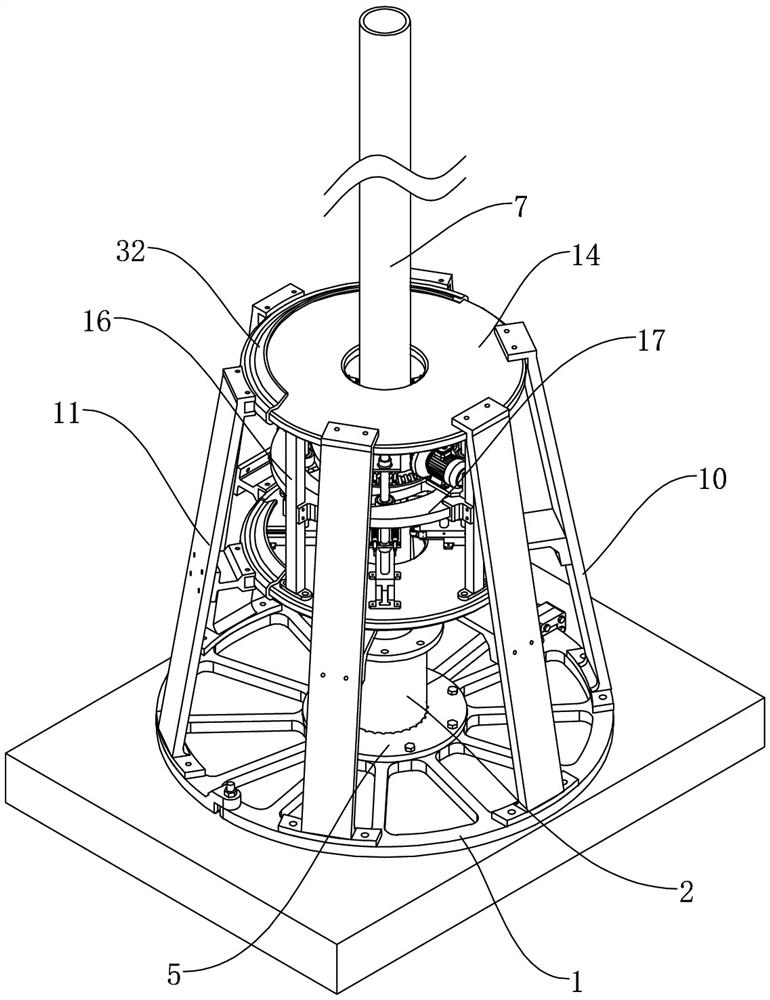

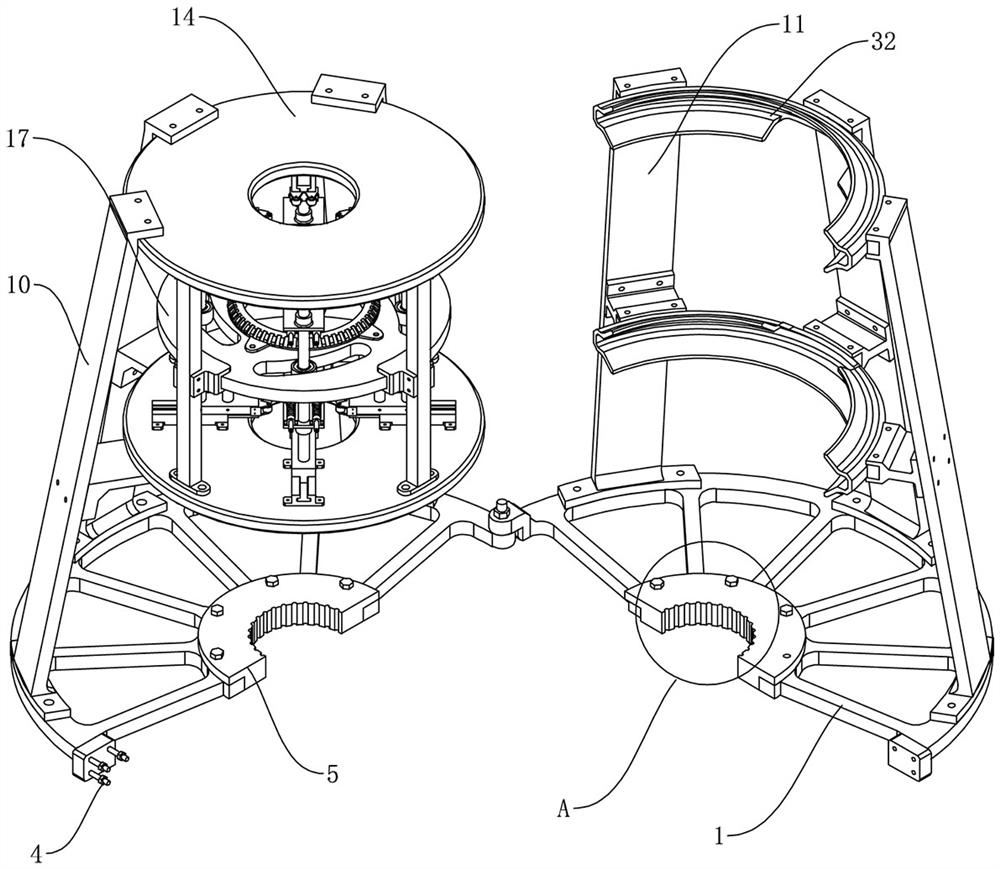

[0051] refer to Figure 1 to Figure 10 As shown, a wellhead docking device includes:

[0052] Two half-ring horizontal support frames 1 located on the ground are arranged coaxially with the wellhead assembly 2, the lower casing 3 is fixed in the wellhead assembly 2, and the lower casing 3 is arranged coaxially with the wellhead assembly 2, And the upper end of the lower casing 3 passes upwards out of the wellhead assembly 2, one end of the two half-ring horizontal support frames 1 is hinged to each other, and the other ends of the two half-ring horizontal support frames 1 are fixedly connected by several first bolts 4, each Each half-ring horizontal support frame 1 is fixedly provided with a coaxial half-ring clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com