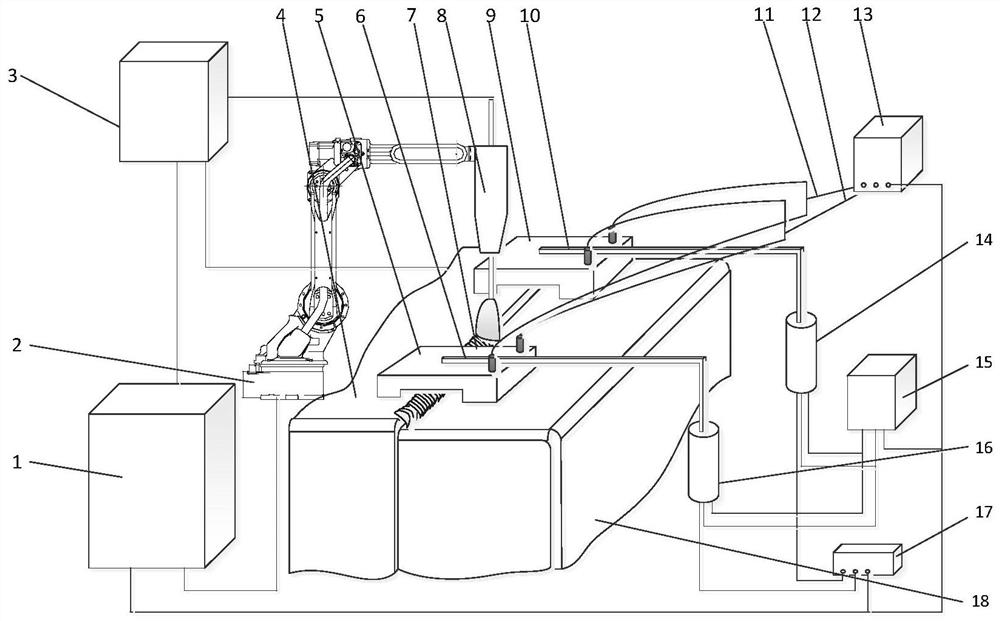

Automatic welding device and method achieving low deformation for circular seam of thin-wall aluminum alloy oil tank

An automatic welding and aluminum alloy technology, which is applied in welding equipment, welding equipment, auxiliary devices, etc., can solve problems such as difficulty in implementing automatic welding, deformation of plates, etc., achieve efficient and fast robot welding, improve welding efficiency, and realize the effect of robot welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

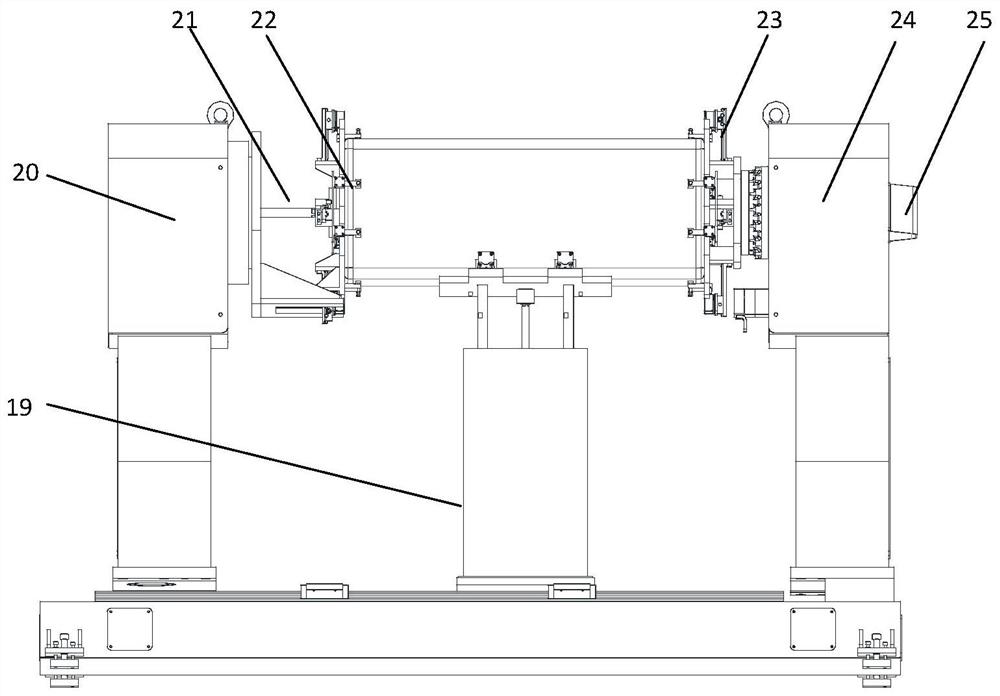

[0038] The invention provides a low-deformation welding method for the front weld seam of a thin-walled aluminum alloy fuel tank, which can realize the automatic welding of the peripheral weld seam of the aluminum alloy fuel tank without spot solidification, and is aimed at a 2mm thick aluminum alloy box body with a length of the end surface of the box body of 200mm. For the welding of the circumferential seam around the fuel tank, the specific steps are as follows:

[0039] Preferably, the material of the refrigeration compression module of the device is copper or brass, and the distance between the two is 60mm;

[0040] As a preference, the refrigeration compression modules are respectively compressed on the left and right sides of the position to be welded on the box body plate and the end plate, and the distance from the weld center is 20 mm;

[0041] As a preference, the length of the refrigeration compression module along the center of the weld is 40mm, and the width of th...

Embodiment 2

[0050] The invention provides a low-deformation welding method for the front weld seam of the thin-walled aluminum alloy fuel tank, which can realize the automatic welding of the peripheral weld seam of the aluminum alloy fuel tank without spot solidification. For circular seam welding, the specific steps are as follows:

[0051] Preferably, the material of the refrigeration compression module of the device is brass, and the distance between the two is 60mm;

[0052] As a preference, the refrigeration compression module is respectively compressed on the left and right sides of the position to be welded on the box body plate and the end plate, and the distance from the weld center is 35mm;

[0053] As a preference, the length of the refrigeration compression module along the center of the weld is 40mm, and the width of the refrigeration compression module along the vertical axis is 90mm;

[0054] The specific implementation of the method includes:

[0055] (1) Set the welding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com