Automatic double-screw bolt driving machine for water outlet plate

A water outlet plate and stud technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of high labor intensity, low work efficiency, low installation accuracy, etc., and achieve low labor cost, high work efficiency, and welding high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

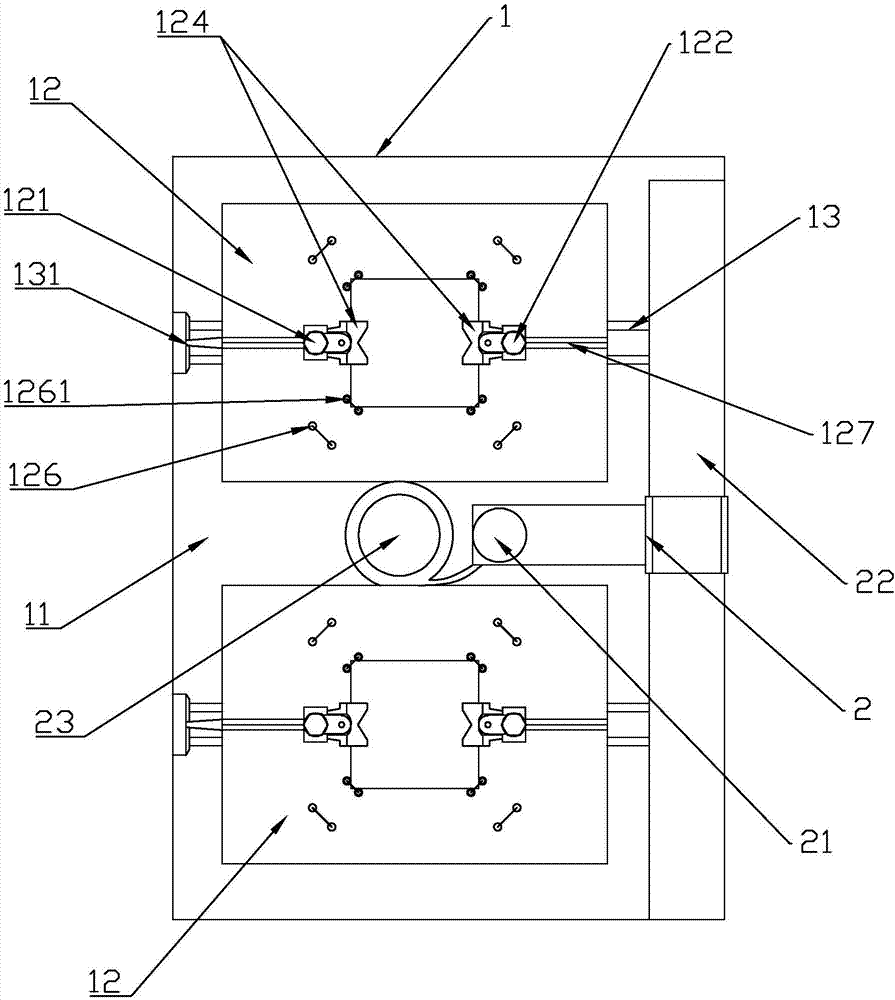

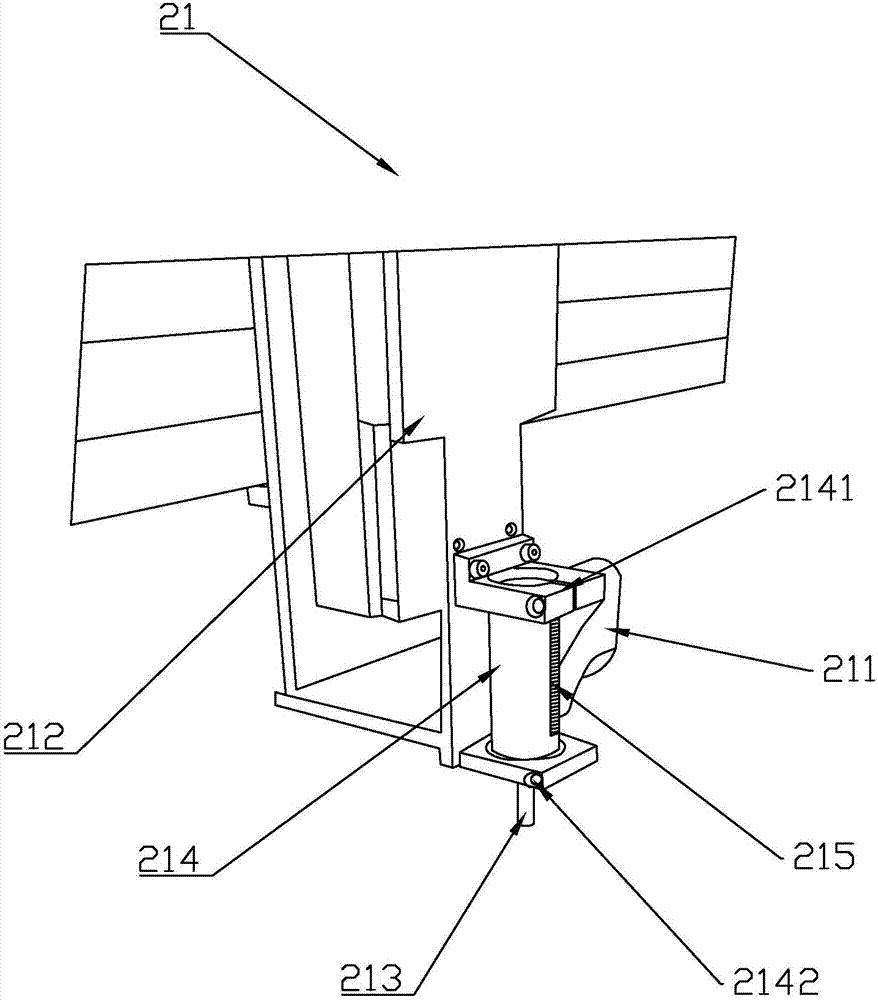

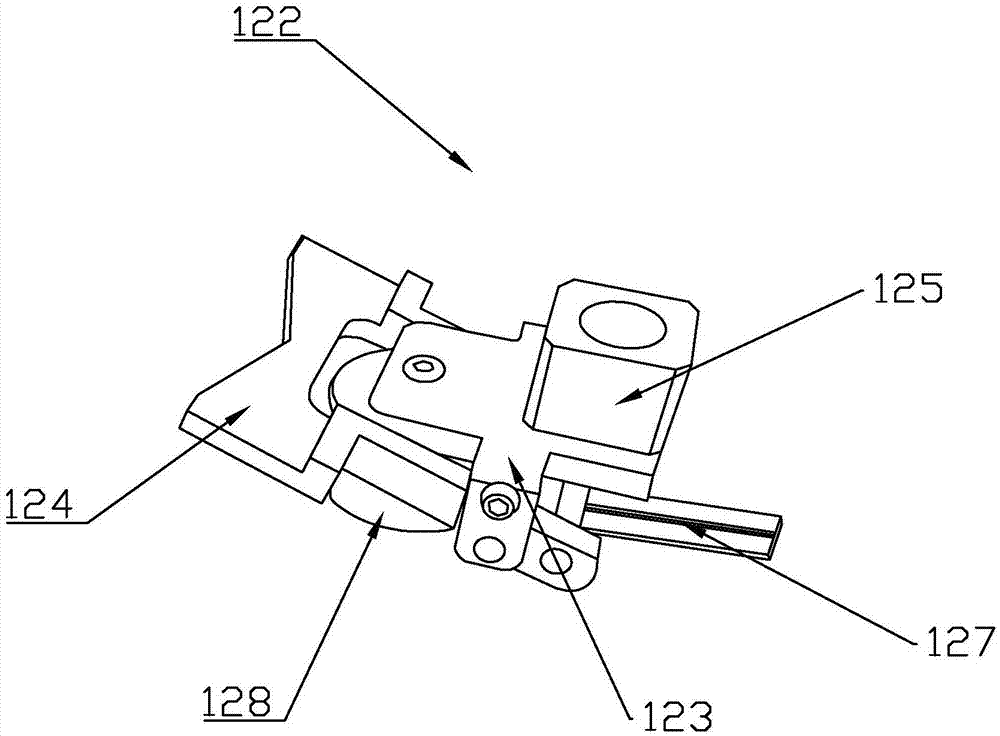

[0016] Such as figure 1 Shown is a structural diagram of a preferred embodiment provided by the present invention. refer to Figure 1 to Figure 3 As shown, the water outlet plate automatic stud driving machine in this embodiment includes a welding platform 1 and a welding mechanism 2 erected on the welding platform 1 for automatic welding. The welding platform 1 includes a frame 11 and is slidably installed on the frame 11. The positioning platform 12, the left clamp 121 and the right clamp 122 for clamping workpiece are symmetrically installed on the positioning platform 12; And the driving cylinder 125 arranged at the other end of the hinge seat 123, the driving cylinder 125 controls the clamp arm 124 to position the workpiece. In this embodiment, the positioning platform 12 is provided with positioning holes 126 symmetrically arranged along the surface contour of the workpiece, and the positioning pins 1261 for clamping the outer periphery of the workpiece are detachably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com