A cylinder robot welding workstation

A robot welding and workstation technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of not using fully automatic robots, high labor intensity, and low work efficiency, so as to improve labor efficiency and reduce The effect of labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

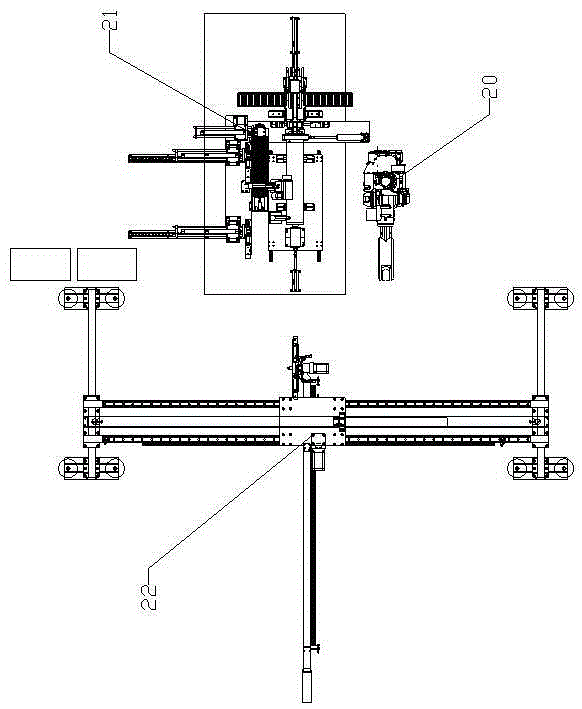

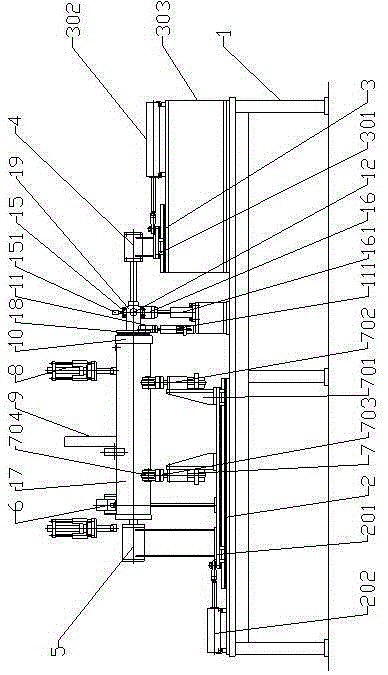

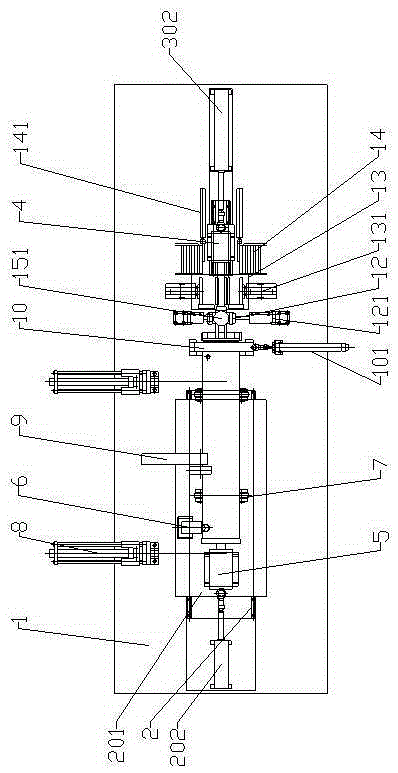

[0018] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 5 As shown, this kind of cylinder robot welding workstation includes a six-degree-of-freedom welding robot 20 for grabbing the cylinder 17, a cylinder support positioning table 21 for supporting the cylinder 17, and a three-degree-of-freedom rectangular Coordinate servo oil cylinder upper and lower parts manipulator 22, six degrees of freedom welding robot 20 and three degrees of freedom Cartesian coordinate servo oil cylinder upper and lower parts manipulator 22 are prior art, and will not be repeated here. Frame 1 is provided with left slide rail 2 and right slide rail 3, and left slide rail 2 is provided with left slide plate 201, and left slide plate 201 is connected with left slide cylinder 202, and frame 1 is provided with right bracket 303, right The slide rail 3 is positioned on the right bracket 303, the right slide rail 3 is provided with a right slide plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com