Automatic cylinder welding device

An automatic welding and cylinder technology, applied in the field of mechanical processing, can solve the problems of increased difficulty in manual operation, low welding efficiency, and large area occupied by the welding site, so as to save welding time, uniform circumferential weld seam, improve welding efficiency and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described further in conjunction with accompanying drawing now, and the present invention size can be made according to actual working condition.

[0023] The electric control box in this embodiment can be purchased commercially.

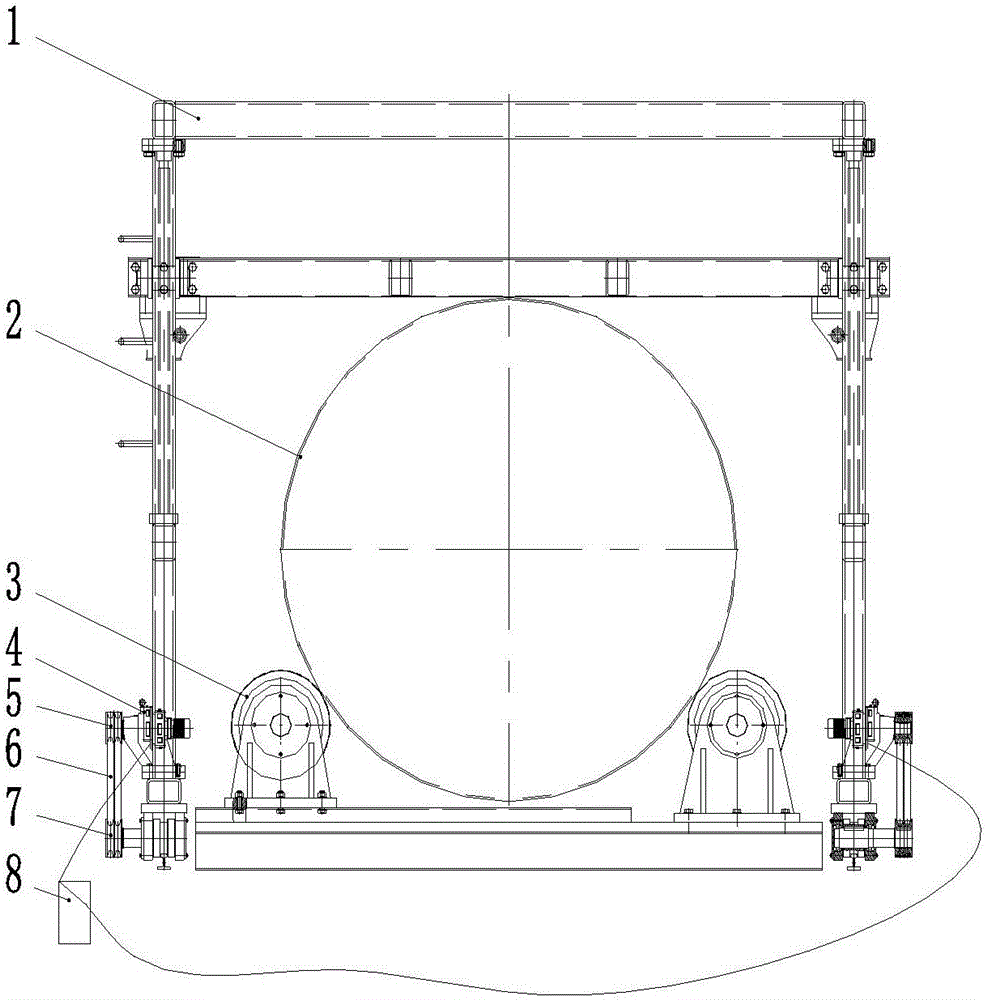

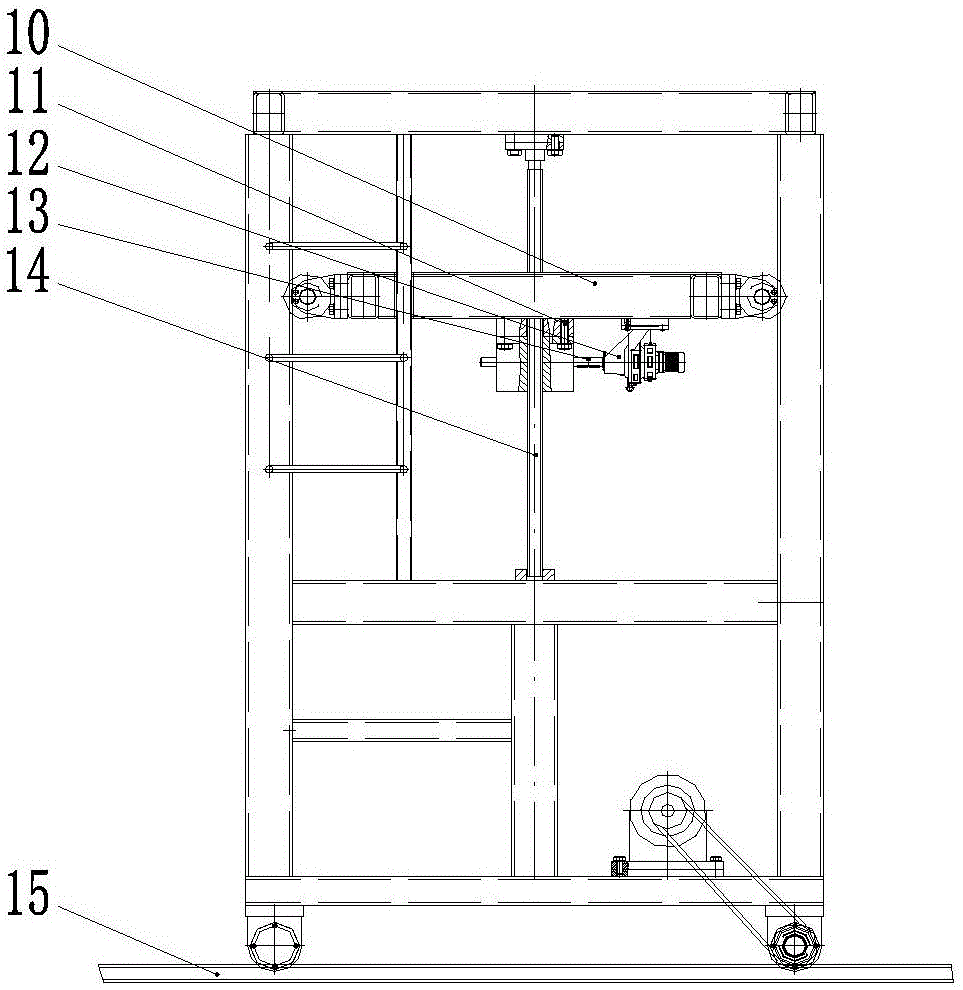

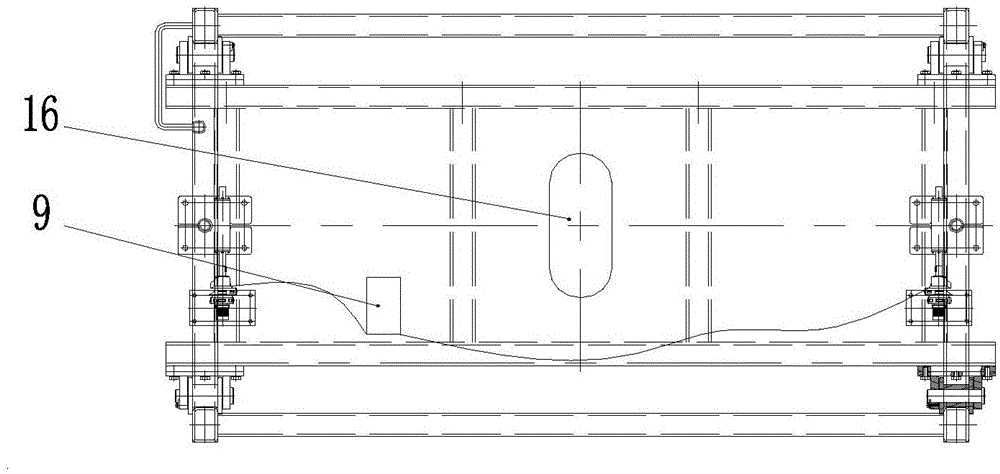

[0024] An automatic cylinder welding device includes a traveling mechanism 1 , an overturning mechanism 3 , a base 24 , rails 15 , a frequency converter 8 and an electric control box 9 .

[0025] Described walking mechanism comprises console 10, console lifting motor 11, belt 6, small pulley 5, large pulley 7, traveling wheel, frame, worm wheel 13 and leading screw 14; Rail 15, the track rail is fixed on the left and right sides of the base; the length of the guide rail can be determined according to the length of the welding cylinder. The traveling wheel of traveling mechanism 1 is installed in track 15, and traveling mechanism 1 can slide back and forth along track 15; The bottom of traveling mechanism 1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com