Rapid welding device

A rapid welding and electric cylinder technology, applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve problems such as poor reliability and easy burns, and achieve the effect of ensuring welding safety and welding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

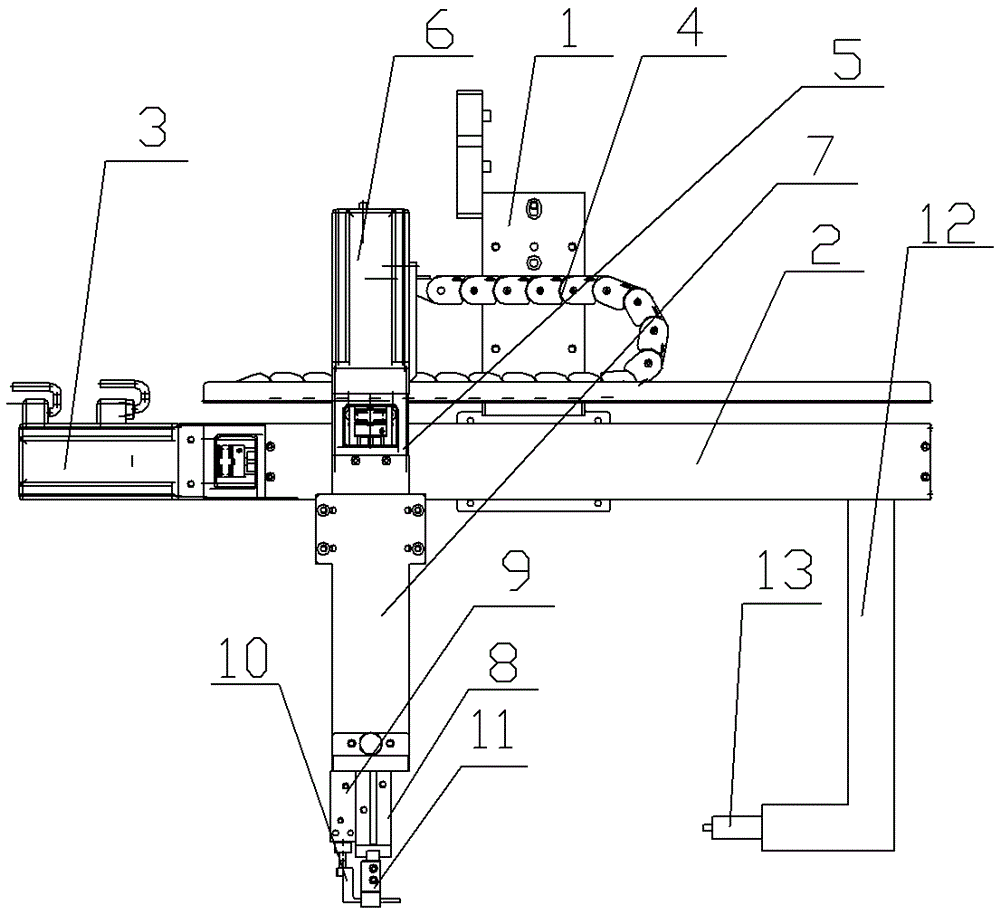

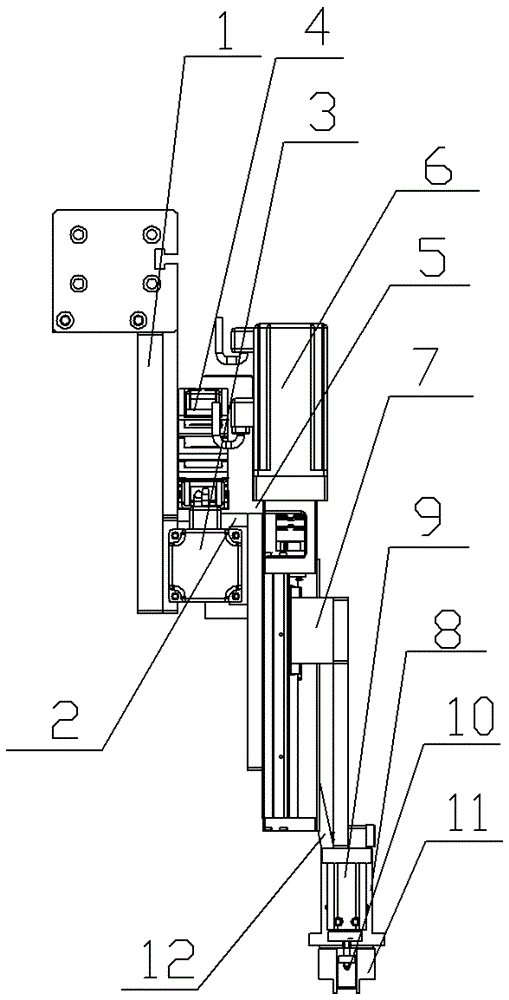

[0009] See figure 1 , figure 2 As shown, a rapid welding device includes a suspension bracket 1, a horizontal electric cylinder mechanism is installed on the suspension bracket 1 through a horizontal support seat 2, and the horizontal electric cylinder mechanism includes a horizontal driving servo motor 3, a horizontal screw rod and a connecting horizontal The horizontal slider 5 of the screw rod is equipped with a longitudinal electric cylinder mechanism on the horizontal slider 5. The longitudinal electric cylinder mechanism includes a longitudinal servo motor 6, a longitudinal screw rod and a longitudinal slider 7 connected to the longitudinal screw rod. The bottom of the longitudinal slider 7 is installed There are jaw cylinder 8 and limit cylinder 9, L-shaped limit block 10 is installed on the piston rod of limit cylinder 9, L-shaped limit block 10 is arranged between two jaws 11 of jaw cylinder 8, horizontal An L-shaped support base 12 is installed on the end of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com