Ball-locking type emergency repair leakage stoppage plate and method for repairing pipeline in emergency through ball-locking type emergency repair leakage stoppage plate

A plugging plate and ball lock technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problem of less application, and achieve the effects of saving operating costs, good sealing performance, and good oil corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

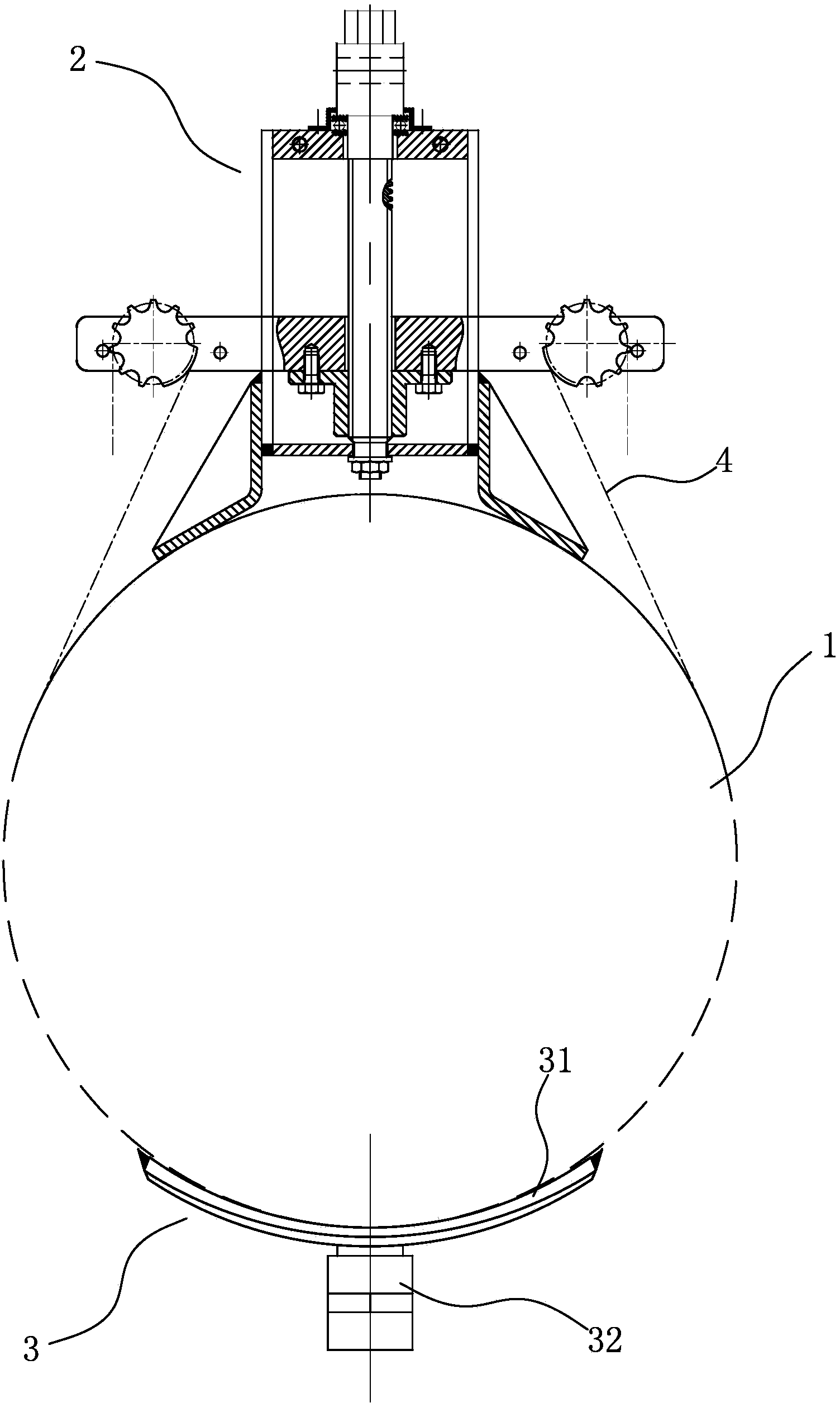

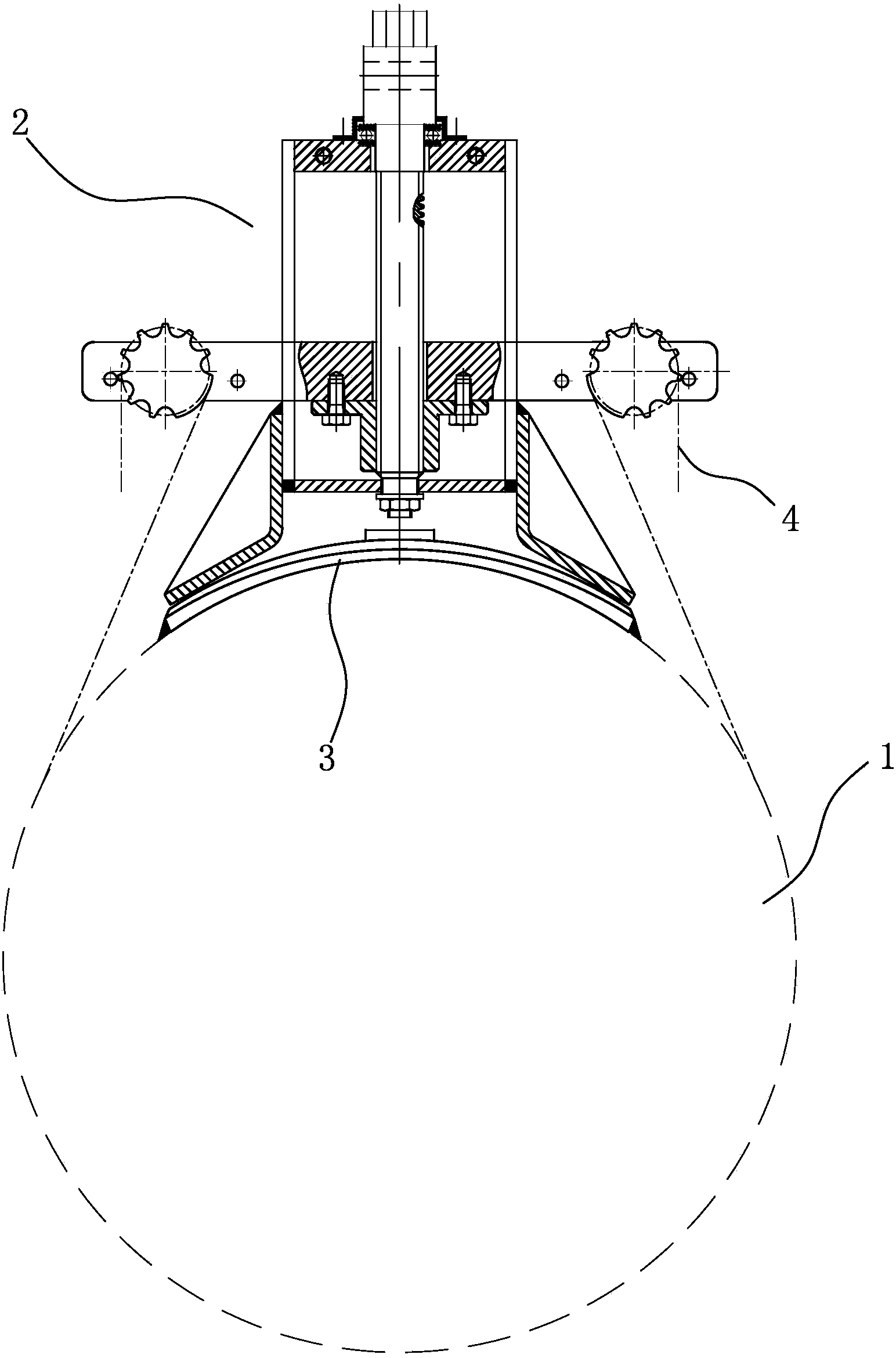

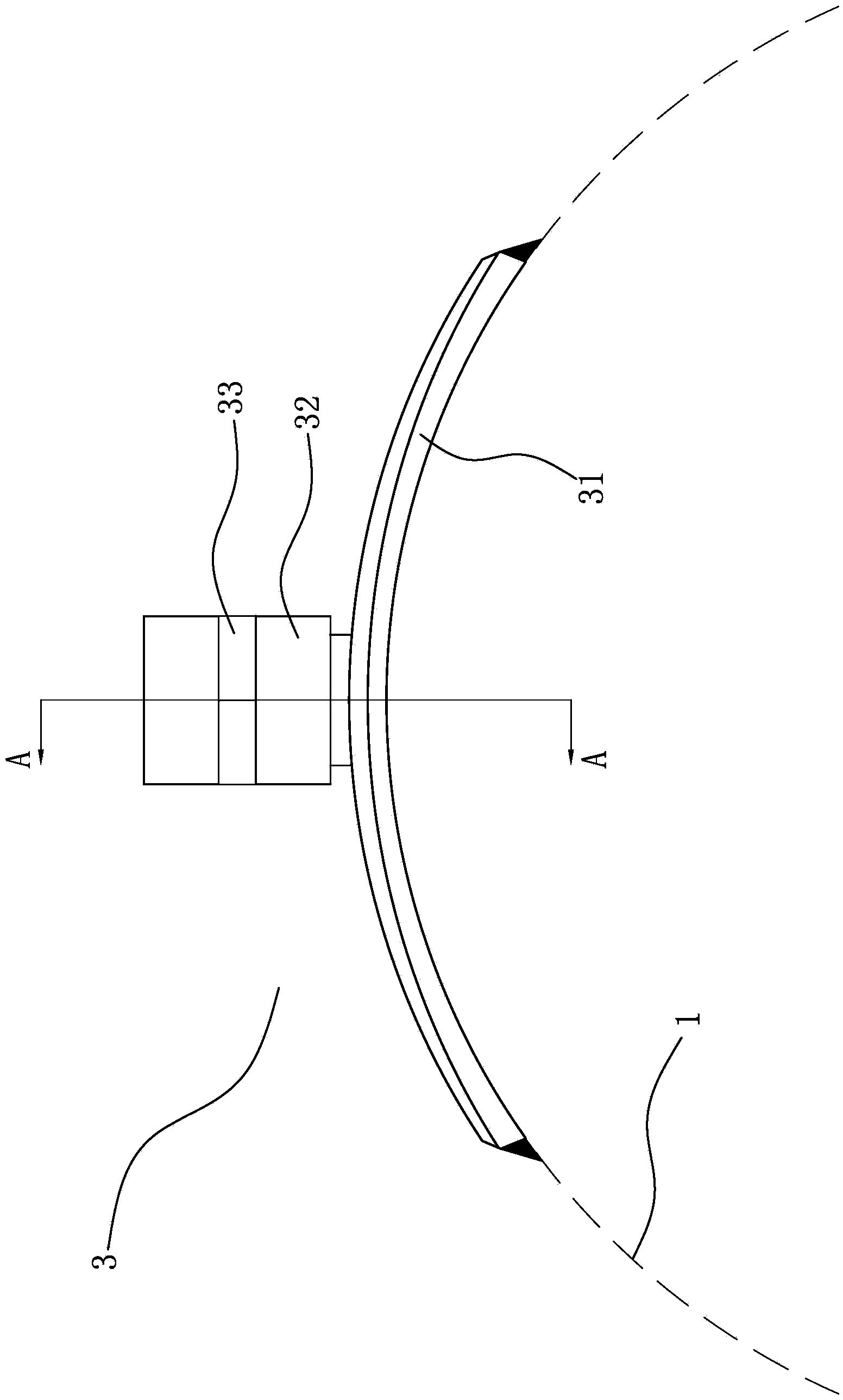

[0039] Such as Figure 1-7 shown, see Figure 4 , A ball-lock emergency repair plugging plate of the present invention includes a plate body 31 , a valve 32 and a sealing ball 321 . A vent hole is opened in the middle of the plate body 31 . A valve 32 is provided on the exhaust hole. The inner lower part of the valve 32 is a cylindrical hole, and the upper part is a circular platform hole. The circular platform hole is a circular platform hole with a small upper part and a larger lower part, and a sealing ball 321 is arranged in the valve 32 . The diameter of the sealing ball 321 is larger than the upper end of the circular table hole and smaller than the lower end of the circular table hole, and the sealing ball 321 is connected with the bottom of the valve 32 by a spring.

[0040] see Figure 4 , Figure 5 , The leak plugging plate 3 also includes an adapter 33 , a bolt 34 and a valve cap 35 . The top of the valve 32 is threadedly connected with an adapter 33 . The i...

Embodiment 2

[0054] A method for urgently repairing a pipeline with a ball-lock type leak plugging plate, comprising the following steps:

[0055] A. Thread the valve 32 of the plugging plate 3 to the adapter 33, and screw down the bolt 34 in the middle of the adapter 33, so that the bolt 34 pushes down the sealing ball 321 to open the ball lock;

[0056] B. Place the middle part of the plugging plate 3 on the leakage of the pipeline 1;

[0057] C. Connect the two sets of fixtures 2 with the plugging plate 3 at the same side of the leakage of the pipeline 1;

[0058] D. Fix both ends of the chain 4 with the fixture 2, and the fixture 2 fixes the leak-stopping plate through the chain groove of the leak-stopping plate 3;

[0059] E. The fixture 2 tightens the plugging plate 3 through the chain 4;

[0060] F. Weld with the pipe 1 along the outer edge of the plugging plate 3 that is not blocked by the fixture 2;

[0061]G. Remove the fixture 2, and weld the outer edge of the plugging plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com