Three-axis stator iron core welding machine

A stator core and welding machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low welding efficiency of stator core, cumbersome punching and clamping and positioning, long loading and unloading Time and other issues, to achieve the effect of ensuring product stacking coefficient, convenient adjustment and operation, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0030] The invention discloses a three-axis stator iron core welding machine, which is used for welding electric shock punching sheets and can improve welding efficiency. The following are specific examples:

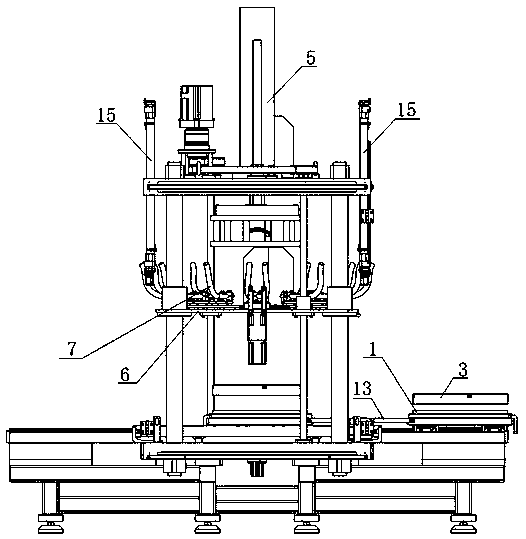

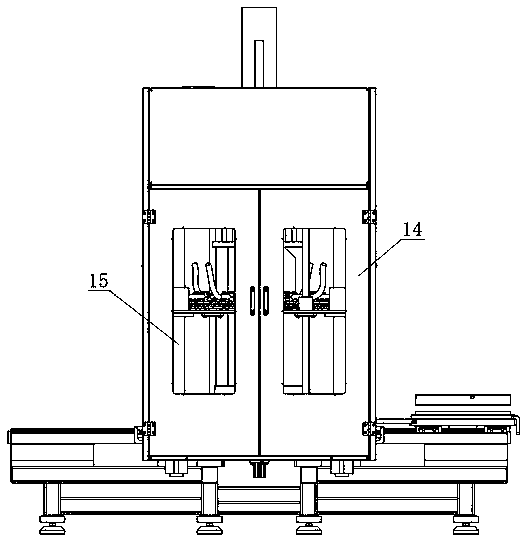

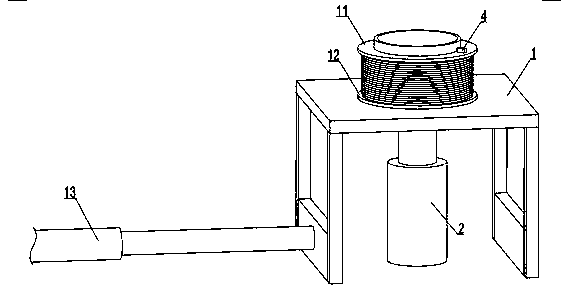

[0031] The three-axis stator core welding machine of the present invention includes a welding part, a clamping part and a switching part. The welding part is used for specific welding work and has welding machine parts. The clamping part has two stations, and the welding work can be continuously performed by switching between the two stations. The switching part is used for switching the working states of the two stations. The switching part continuously moves the two stations to the welding area where the welding part is located. The clamping part, the welding part and the switching part will be described in detail below. Specific as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com