Device and method for processing multi-chamber magnesium-aluminum alloy parking air storage cylinder

A magnesium-aluminum alloy and processing device technology, which is applied to metal processing equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of difficulty in grasping the positioning accuracy of the partition, shifting and tilting of the partition, and affecting the welding strength, etc., to achieve improved welding effect, accurate inclination angle, and the effect of improving welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

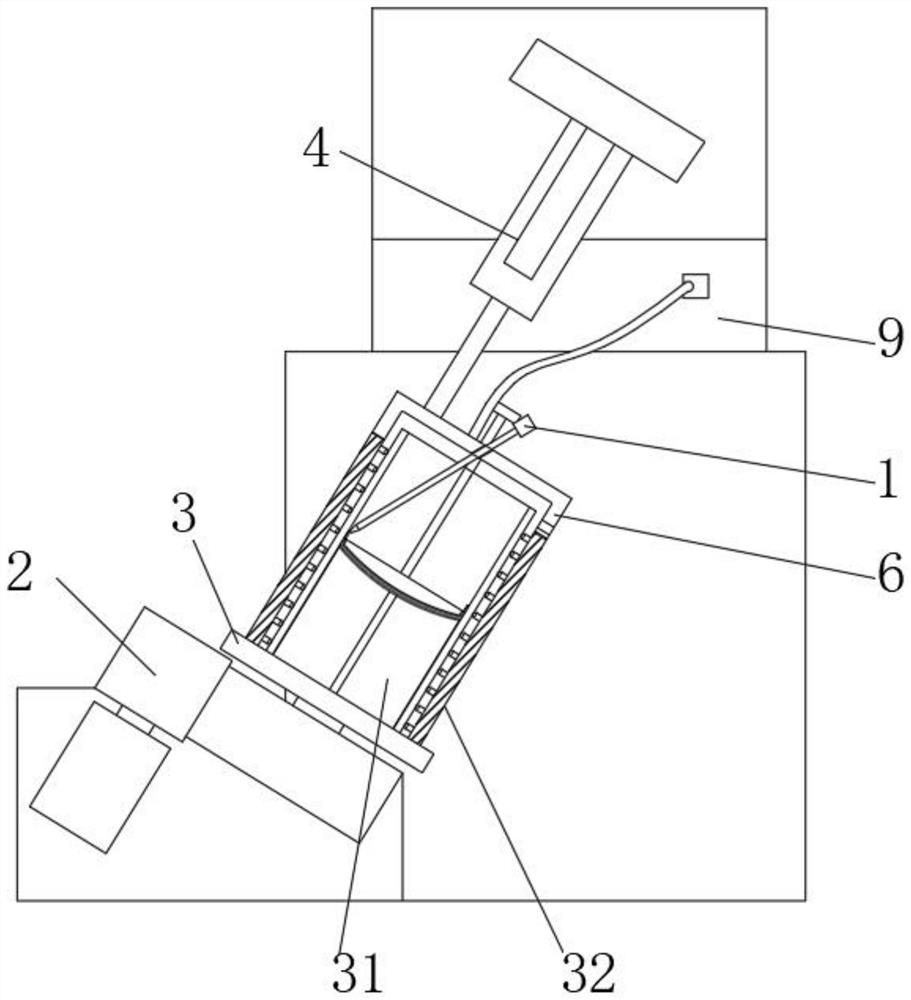

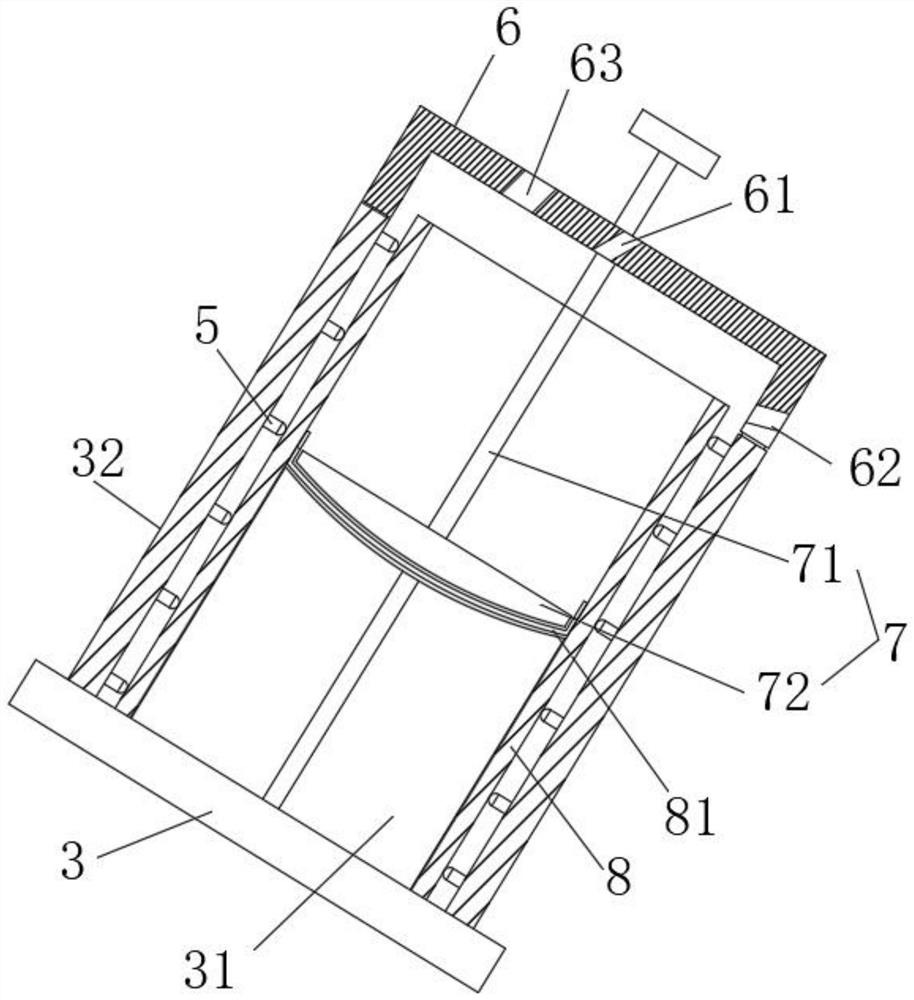

[0042] A multi-chamber magnesium-aluminum alloy parking air storage cylinder, including a rotating motor 2, the rotating motor 2 is arranged obliquely, the output end of the rotating motor 2 is equipped with a base plate 3, and the rotating motor 2 is used to drive the base plate 3 to rotate and tilt It is set to ensure that the gas storage tank can form a certain angle with the welding torch, making the welding operation more convenient;

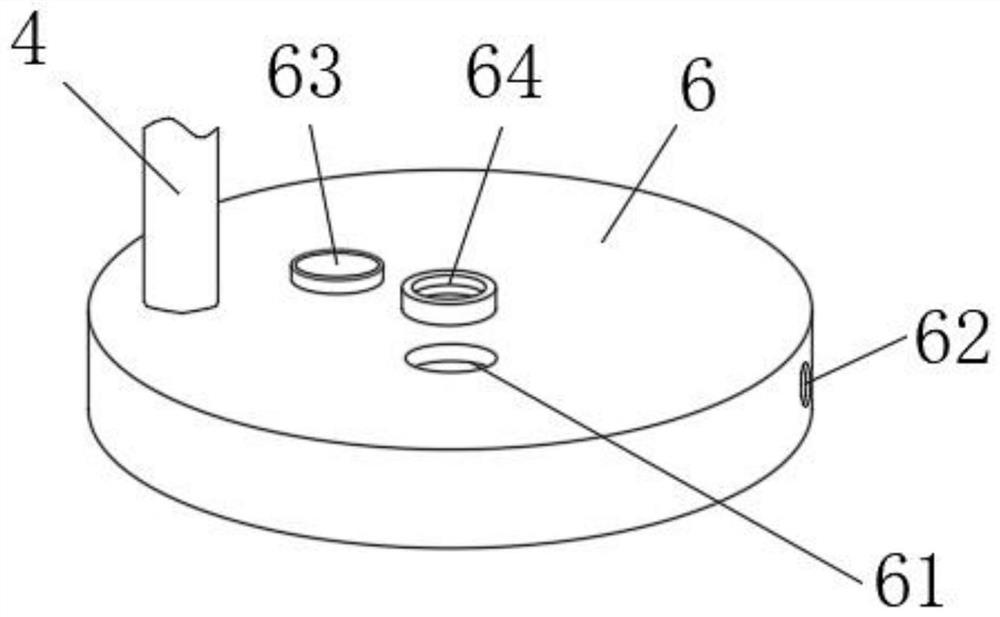

[0043] The center of the surface of the base plate 3 is equipped with an inner positioning seat 31 and an outer positioning tube 32, and the outer positioning tube 32 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com