Thermoelectric separation power type light-emitting diode bulb with high integration and high lighting effect

A technology of light-emitting diodes and thermoelectric separation, which is applied to semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, light sources, etc. Stable and easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

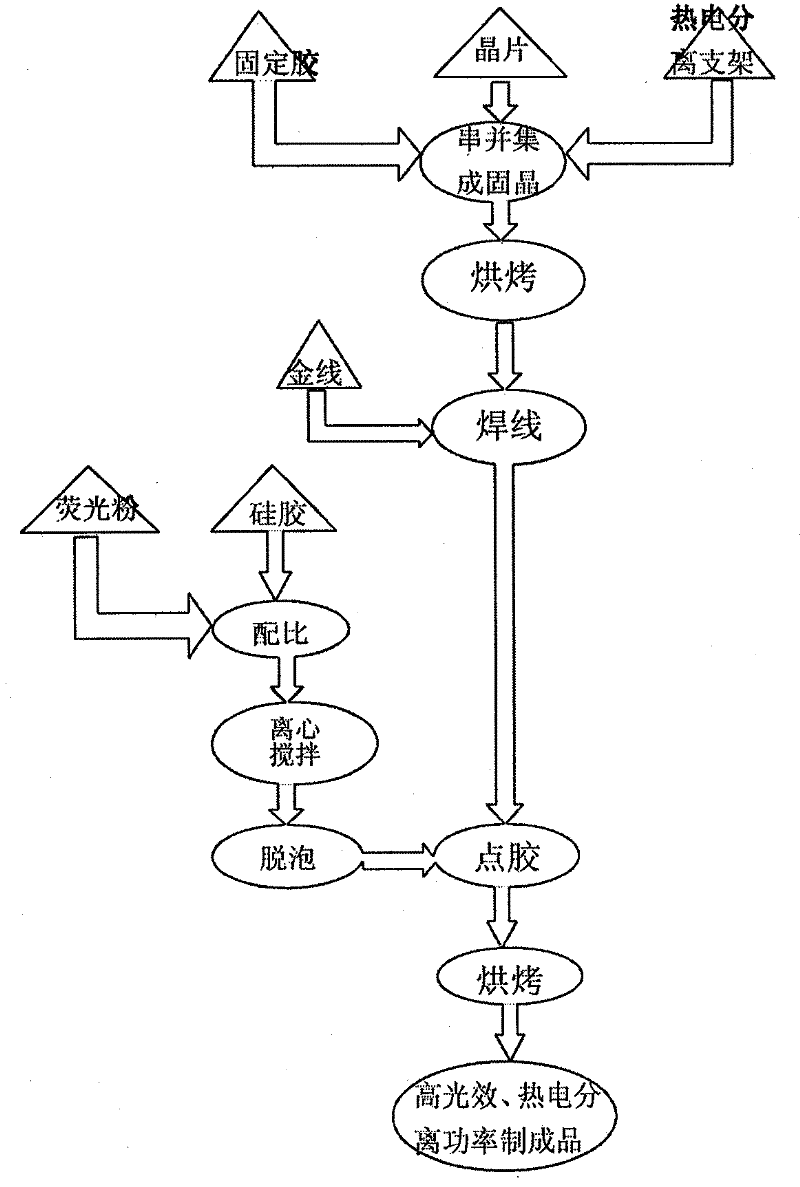

Method used

Image

Examples

Embodiment Construction

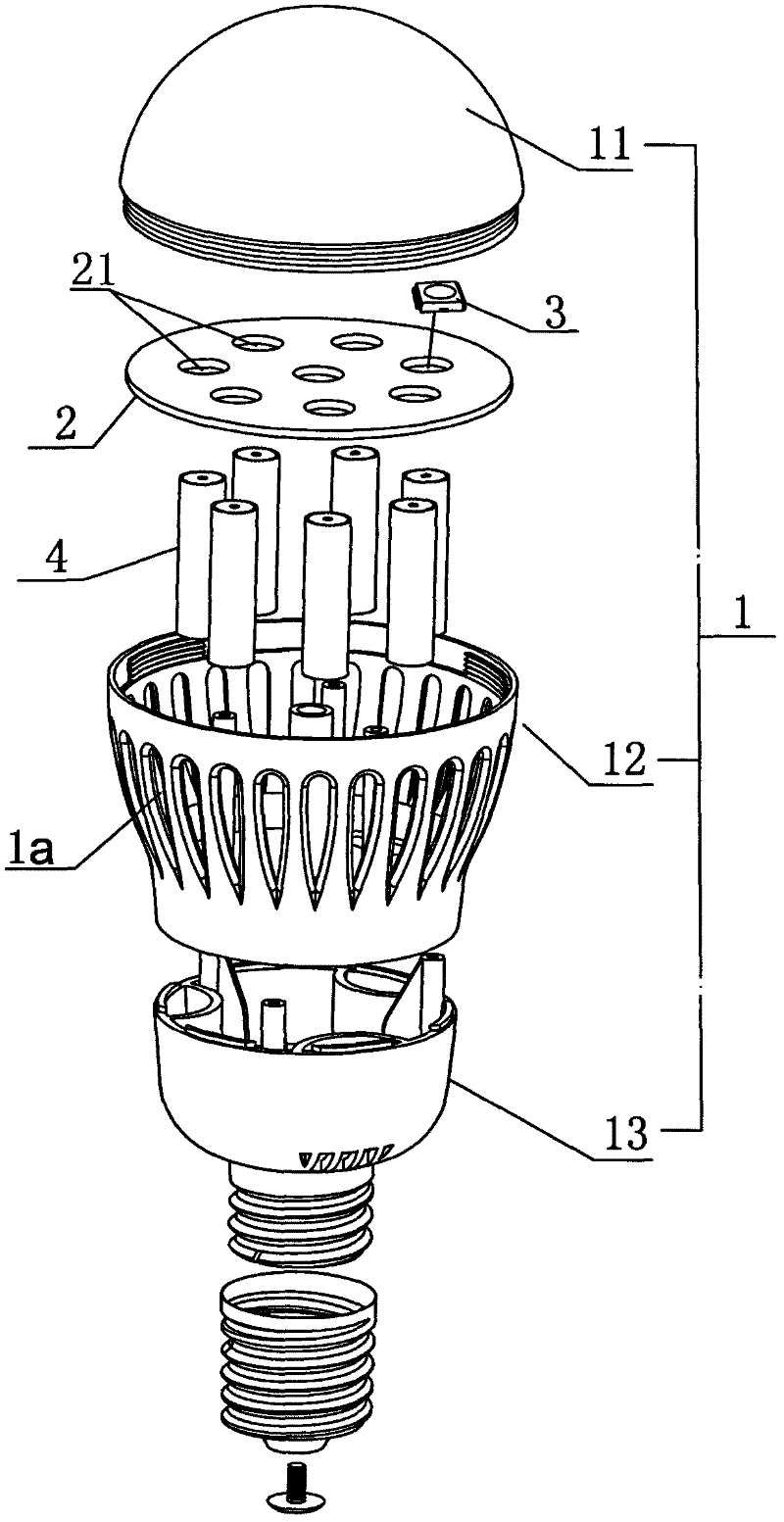

[0042] Such as Figure 1 to Figure 7 Shown: a thermoelectric separation power light-emitting diode bulb with high integration and high light efficiency, including a housing 1, a circuit board 2 and a light-emitting diode 3, the circuit board 2 is arranged in the housing 1, and the light-emitting diode 3 is arranged on the circuit board 2, the housing 1 is a non-metallic hollow housing, the lower side is provided with a ventilation hole 1a, and the lower side of the circuit board 2 is provided with a cooling column 4 which is relatively fixed to the light-emitting diodes 3 one by one.

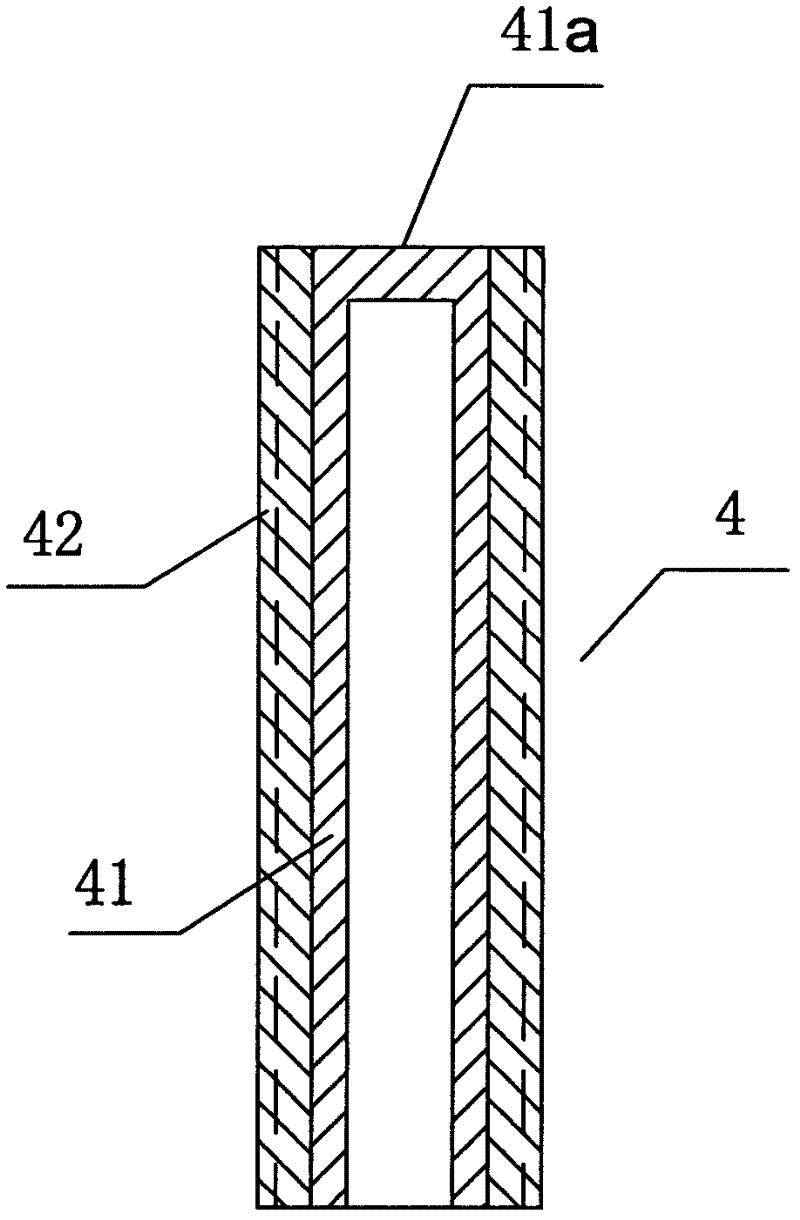

[0043] Such as Figure 2 ~ Figure 4 , Figure 7 As shown, the cooling column 4 includes a heat-conducting copper pipe body 41 and a heat-dissipating graphite layer 42 provided on the surface of the heat-conducting copper pipe body 41 .

[0044] Such as figure 2 As shown, the upper end of the heat-conducting copper pipe body 41 is set as a sealed platform surface 41a.

[0045] The heat dissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com