Manufacturing method of aluminum-substrate printed circuit board in-hole metallization

A technology for printed circuit boards and manufacturing methods, which is applied in the direction of electrical connection formation of printed components, can solve the problems of large pollution, inability to ensure thermal conductivity in holes, complex potassium dichromate treatment process, etc., and achieve high power consumption and convenience The effect of large-scale industrial production and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

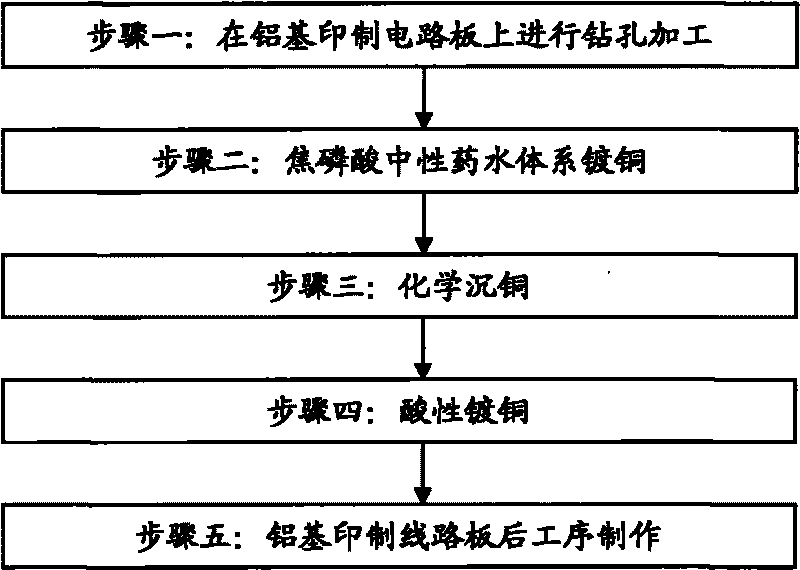

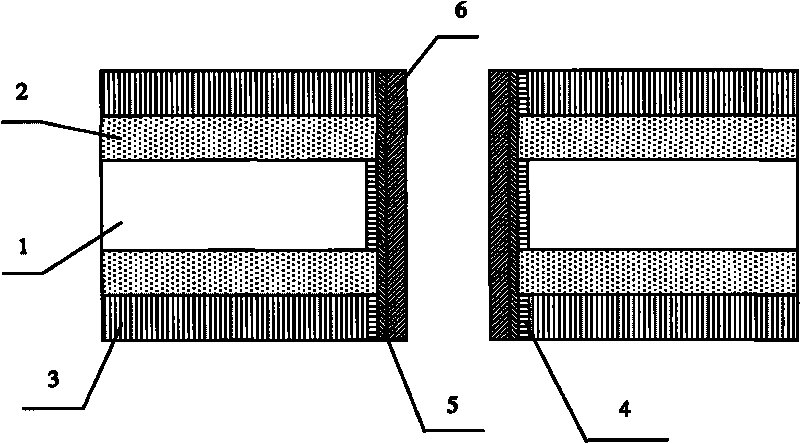

[0019] Such as figure 1 and figure 2 As shown, the present invention electroplates a layer of dense copper protective layer on the surface of the aluminum base through the pyrophosphoric acid neutral copper plating system after the drilling process, which effectively isolates the aluminum base from the strong acid-base potion in the electroless copper plating and acid copper plating process. The contact, so as to realize the metallization in the hole of the aluminum substrate. The aluminum-based printed circuit board includes an aluminum base layer 1 and an insulating dielectric layer 2 and a copper layer 3 sequentially arranged on both surfaces thereof, and the specific steps are as follows:

[0020] Step 1: Carry out drilling processing on the aluminum-based printed circuit board; this step is to carry out the drilling process on the aluminum-based coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com