Tool-free fixed welding method for high-power IGBT module

A technology for fixing tooling and welding methods, which is applied to welding equipment, auxiliary devices, manufacturing tools, etc., can solve problems affecting the long-term service reliability of high-power IGBT modules, reduce production efficiency, and affect welding quality, etc., and achieve online automation The effect of production, simplification of welding process, and avoidance of solder overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

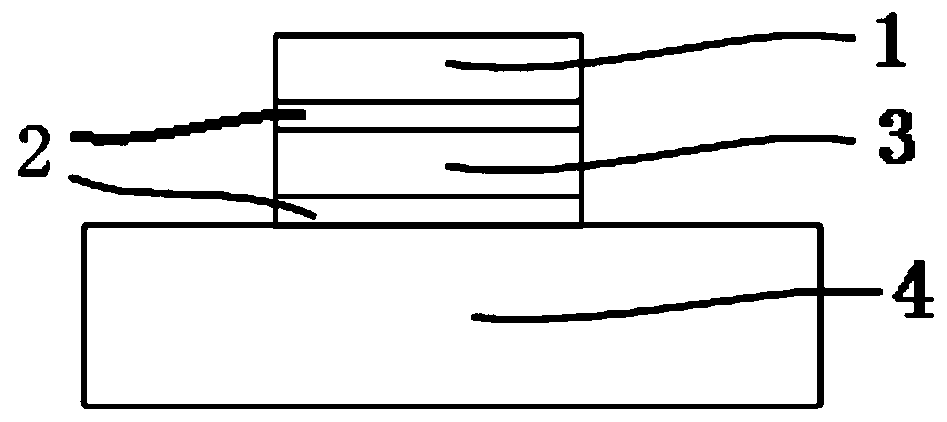

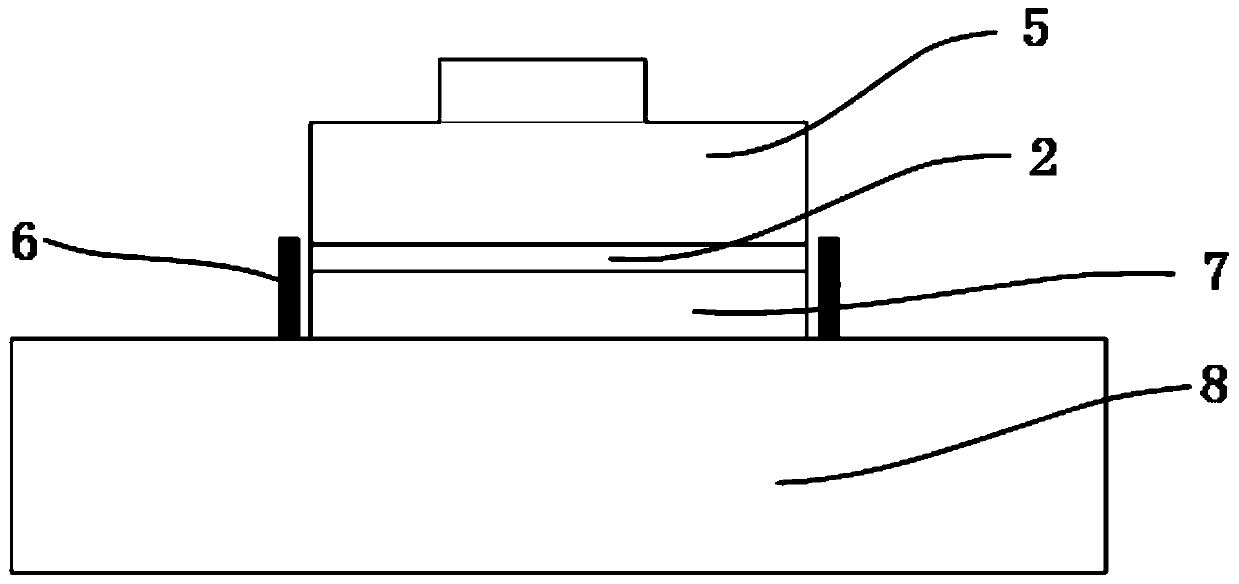

[0026] Such as Figure 1 to Figure 2 As shown, this embodiment uses the EconoDUAL with a voltage of 1700V and a current of 600A TM Take the module of encapsulation type as an example, including the following steps:

[0027] Step 1: Spray 2mg of polymer binder 2 on the back of the primary welding sheet 3, and then place the primary welding sheet 3 on the surface of the DBC liner 5 (copper-clad ceramic liner). The primary welding sheet 3 is a Sn90Sb10 alloy, and the polymer binder 2 is QPAC ® 40. The DBC liner 5 is an alumina ceramic copper-clad liner.

[0028] Step 2: Spray 2 mg of polymer binder 2 on the back of the chip 1, then place the chip 1 on the surface of the primary welding pad 3, assemble it into a lining subunit 5, and then put it into a welding furnace for primary welding. The chip 1 is a silicon-based chip, and the primary sold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com